This guide helps you find the best LVDS tester manufacturer for your needs. We compare key features, functionalities, and considerations to help you choose the right equipment. Learn about different types of testers, their applications, and factors to consider when making your purchase decision.

Low-Voltage Differential Signaling (LVDS) is a crucial technology used in various electronic devices for high-speed data transmission. Ensuring the integrity of LVDS signals is paramount for optimal performance. A reliable LVDS tester is essential for verifying signal quality, detecting faults, and ensuring the smooth operation of devices relying on LVDS technology. This includes applications across numerous industries, from consumer electronics to industrial automation.

Selecting the right LVDS tester manufacturer requires careful consideration of several factors. The ideal manufacturer will offer testers that meet your specific requirements and budget. Let's explore the critical aspects:

The accuracy and precision of the LVDS tester are crucial for reliable testing results. Look for manufacturers that offer testers with high accuracy and low jitter, ensuring accurate signal analysis and fault detection. Manufacturers often specify these metrics in their datasheets – pay close attention to them.

Different LVDS testers offer varying test capabilities. Consider the specific tests you need to perform, such as signal integrity analysis, bit error rate (BER) testing, and eye diagram measurement. Some advanced testers might even incorporate automated test procedures.

A user-friendly interface is essential for efficient testing. Choose a manufacturer that offers intuitive software and hardware, reducing the learning curve and enabling quick setup and operation. Software features like automated reporting and data logging can significantly enhance workflow efficiency.

Reliable after-sales support is crucial. A reputable manufacturer should provide comprehensive technical support, documentation, and prompt service in case of equipment malfunctions. Check their warranty policies and customer support channels.

Consider your future testing needs. Choose a manufacturer that offers scalable solutions to accommodate future expansion and changing requirements. Modular designs allow for upgrades and adaptation to different test scenarios.

While recommending specific manufacturers directly isn't feasible due to constantly changing market dynamics and potential biases, researching reputable companies specializing in test and measurement equipment will lead you to excellent options. Thoroughly review their websites, product specifications, and customer testimonials before making a decision.

The cost of an LVDS tester varies depending on several factors. These include the tester's capabilities (accuracy, speed, features), the brand reputation, and the required level of after-sales support. Higher-end testers with advanced features naturally command higher prices.

The optimal LVDS tester depends entirely on your specific application and requirements. Consider the types of LVDS signals you need to test, the desired accuracy level, and the budget allocated for the equipment. Consult with experts from various manufacturers to find the ideal solution.

Selecting the best LVDS tester manufacturer requires a thorough understanding of your testing needs and a careful evaluation of different manufacturers' offerings. By considering the factors discussed in this guide, you can make an informed decision and select equipment that ensures the reliability and performance of your LVDS-based devices.

| Feature | Importance |

|---|---|

| Accuracy | High |

| Ease of Use | High |

| Test Capabilities | High |

| Cost | Medium |

| Support | High |

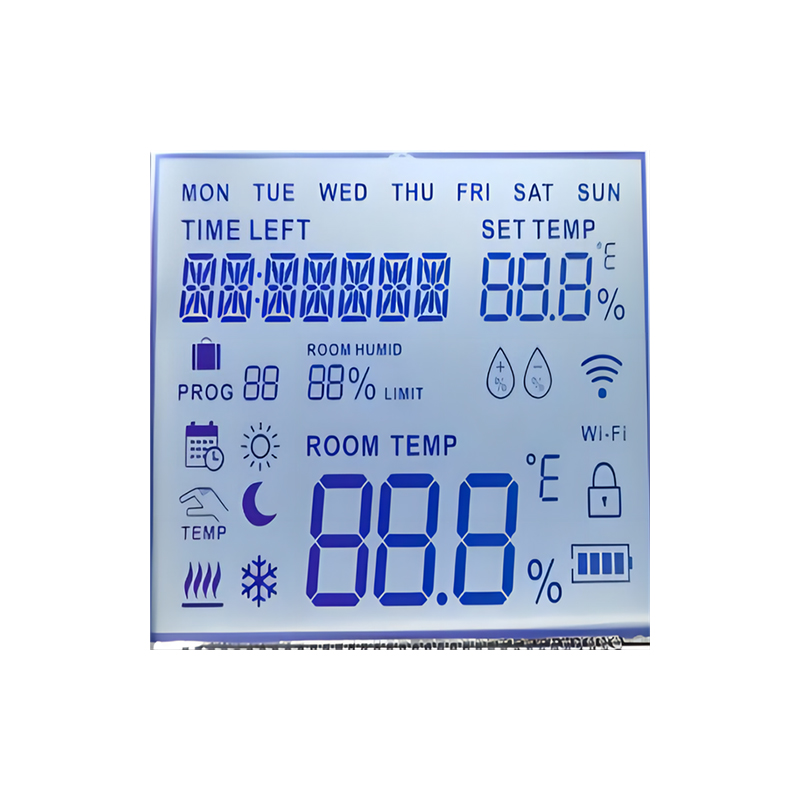

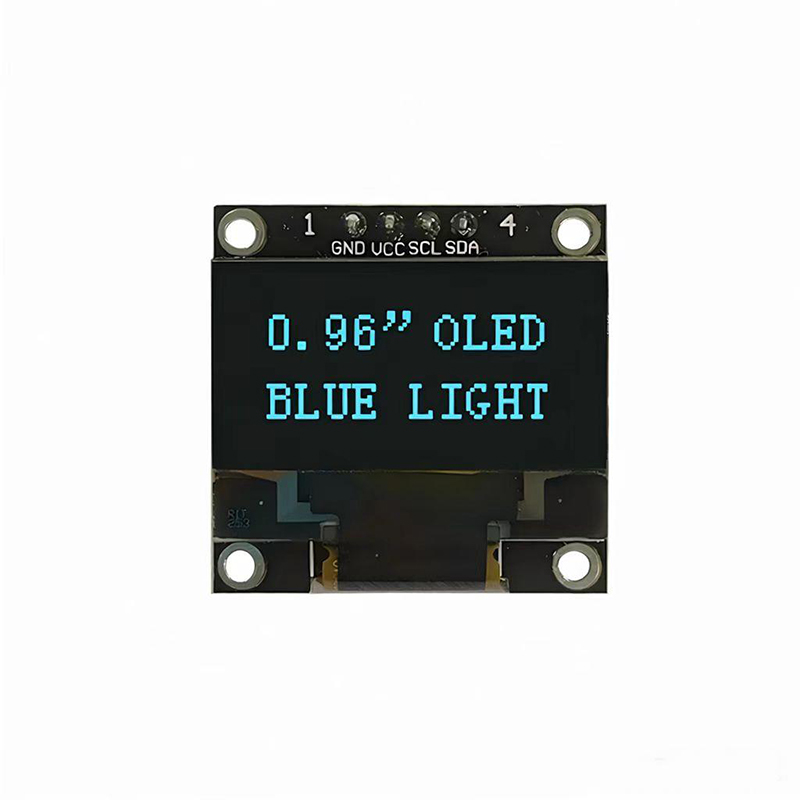

For high-quality LCD and display solutions, consider exploring Dalian Eastern Display Co., Ltd. They offer a wide range of products and services.