Diffusion film LCD converts point light source or line light source (such as LED or CCFL) into uniform surface light source to ensure the brightness and color uniformity of LCD display. The light source of LCD motherboard with diffusion film can directly use LED lamp beads to reduce the cost of backlight source, and can also effectively cover the dots or other optical defects on the light guide plate, so that the brightness of LCD display is more uniform.

The diffusion film of LCD is made by coating optical light-scattering particles on a transparent substrate (usually a PET film), so that light is refracted, reflected and scattered when passing through the film layer, thereby converting uneven light sources into uniform surface light sources. This optical diffusion effect can effectively cover the dots or other optical defects on the light guide plate and improve the display effect. The diffusion film is used in combination with the fully transparent LCD, and the brightness of the LCD display is more uniform. Usually, the diffusion film is applied to the lower surface of the fully transparent LCD.

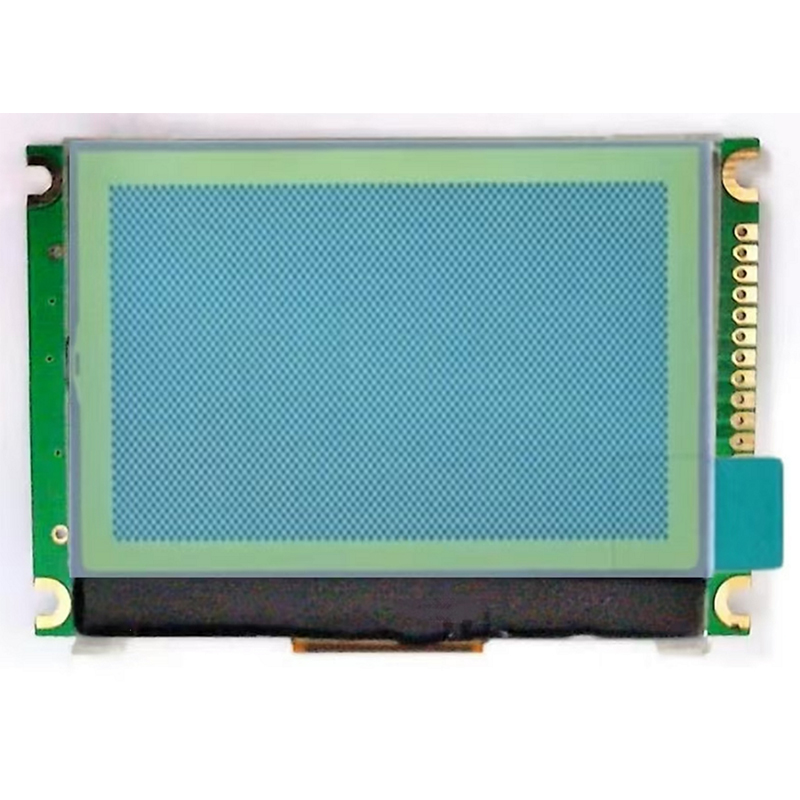

| Manufacturer | EASTERN DISPLAY |

| Contrast | 20-120 |

| Connection method | PIN/FPC/ZEBRA |

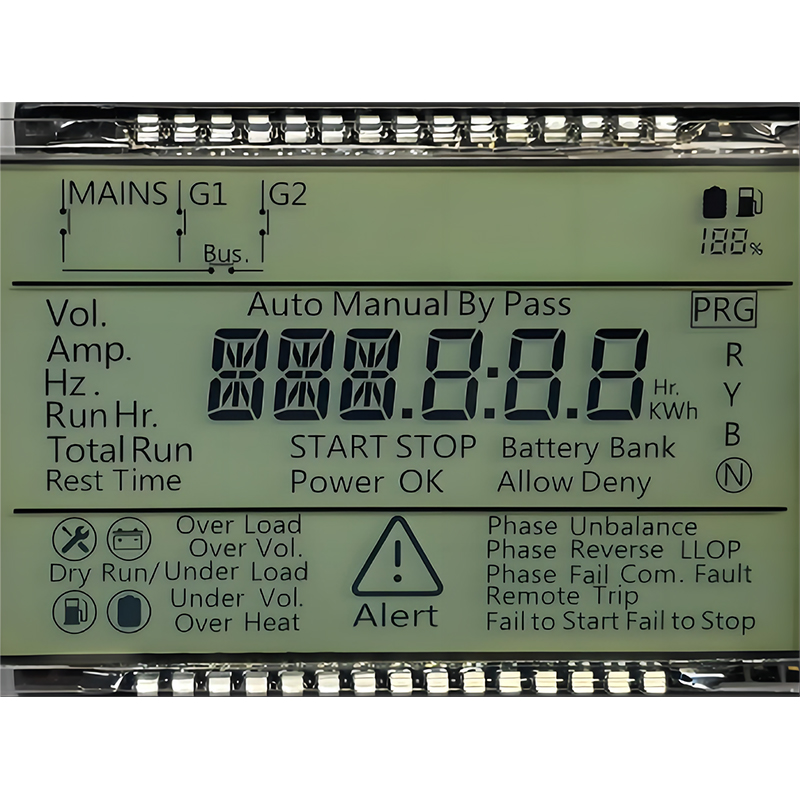

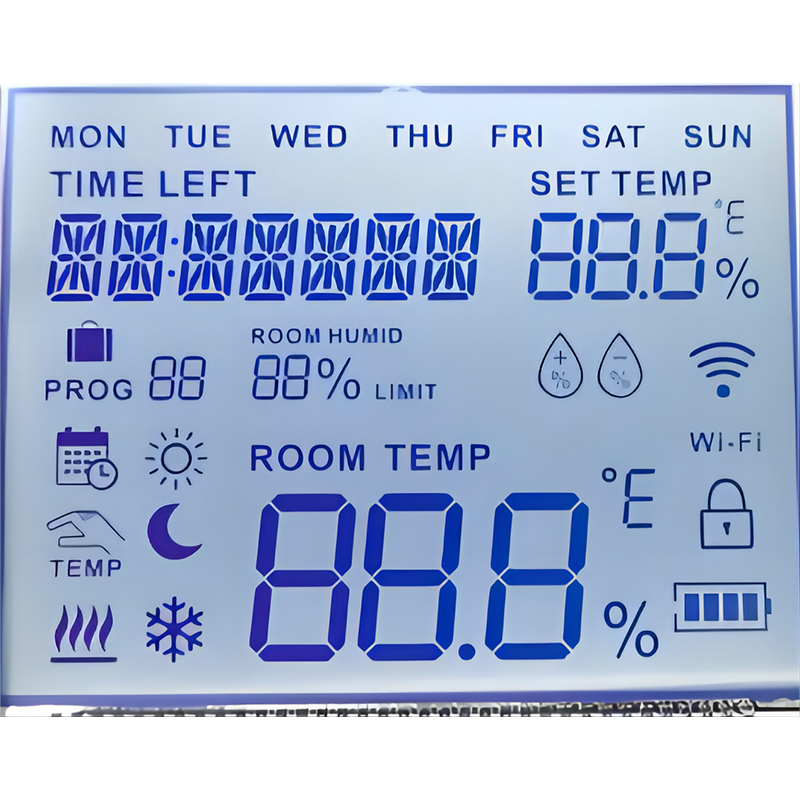

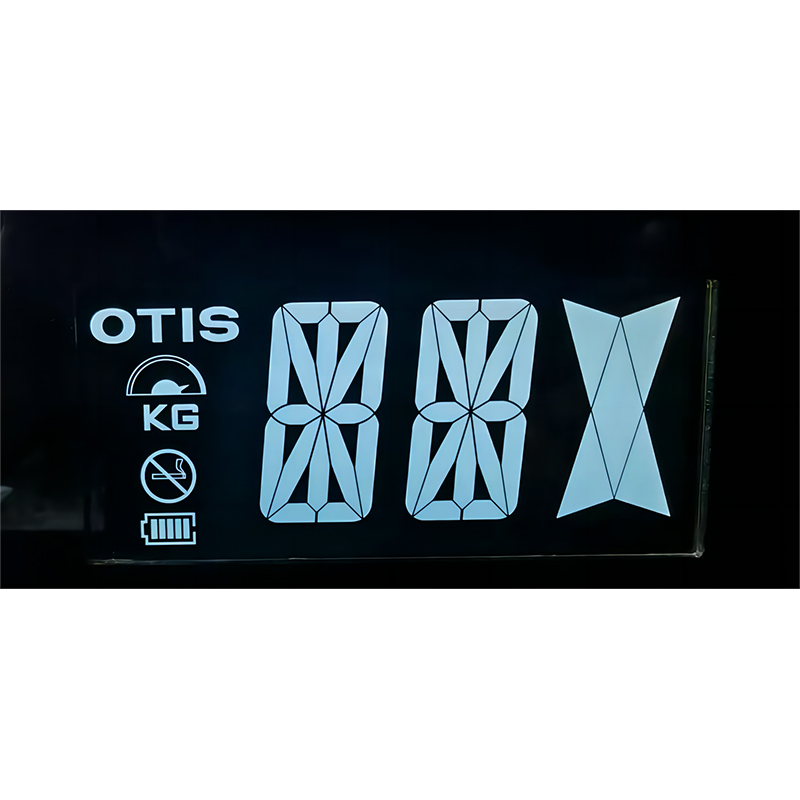

| Display type | Segment LCD /Negative/Positive |

| Viewing angle direction | 6 0’ CLOCK Customization |

| Operating voltage | 2.5V-5V Customization |

| Viewing angle range | 120-150° |

| Number of drive paths | STATIC/ MULTI DUTY |

| Backlight type/color | Customization |

| Display color | Customization |

| Transmittance type | Transmissive |

| Operating temperature | -40-80℃ |

| Storage temperature | -40-90℃ |

| Service life | 100,000-200,000 hours |

| UV resistance | YES |

| Power consumption | Microampere level |