2025-08-28

Cleaning is an important process in the manufacturing process of LCD, and the effect of cleaning directly affects the quality and service life of products. Cleaning methods: In addition to conventional water-based cleaning and air cleaning, UV ultraviolet cleaning is also used in many processes.

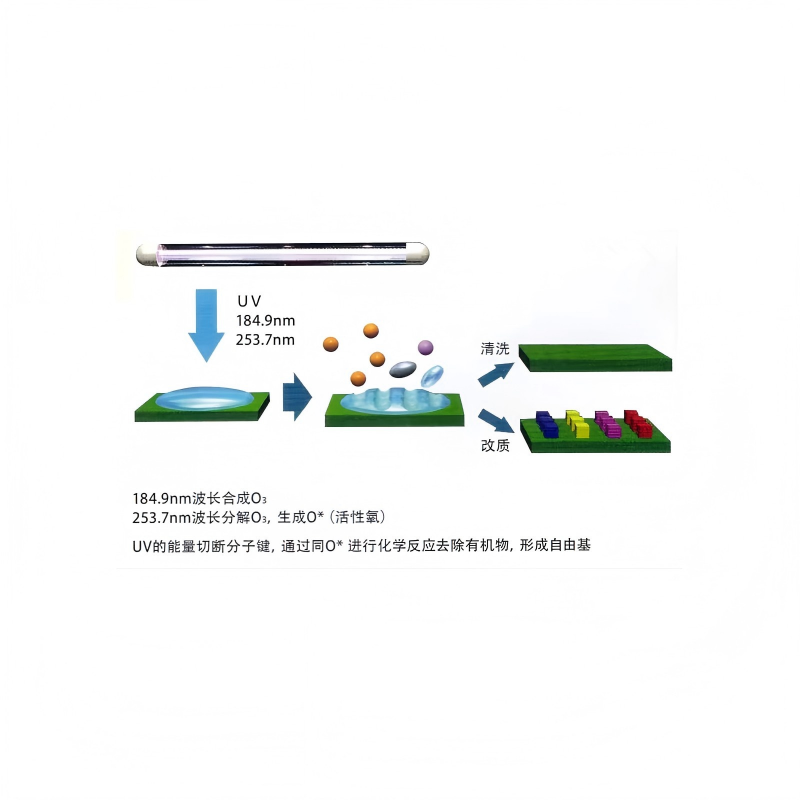

The working principle of UV cleaning technology: This method utilizes the photo-oxidation of organic compounds to remove adhered organic substances from material surfaces, achieving “atomic-level cleanliness” through photolithography. Specifically, UV light sources emit photons at 185nm and 254nm wavelengths, which carry high energy. When these photons strike the surface of materials to be cleaned, most hydrocarbons absorb the 185nm UV light with remarkable efficiency. The absorbed energy then decomposes into ions, free atoms, excited molecules, and neutrons – a process known as photo-oxidation. Simultaneously, oxygen molecules in the air absorb 185nm UV light and generate ozone and atomic oxygen. Ozone exhibits strong absorption of 254nm UV light and further breaks down into atomic oxygen and oxygen gas. The highly reactive atomic oxygen facilitates the decomposition of carbon and hydrocarbon residues on surfaces, converting them into volatile gases like carbon dioxide and water vapor that escape from the material surface. This mechanism thoroughly eliminates carbon and organic contaminants adhering to the material’s surface.

During cleaning, the substrate’s wettability is optimized. Glass substrates are conveyed using rollers while a low-pressure mercury lamp above generates ultraviolet (UV) irradiation. The more UV energy accumulated by the glass substrate, the smaller its surface water contact becomes – this follows an inverse relationship. In TN-LCD/STN-LCD/VA-LCD manufacturing processes, the required UV energy accumulation for glass substrates exceeds 300mj/cm2(253.7nm). For TFT-LCD production, besides ozone cleaning using low-pressure mercury lamps, the mainstream current process employs Excimer Lamps. Their high-reactivity UV light at 172nm wavelength delivers superior cleaning efficiency for glass substrates.

Features of uv light cleaning:

1) It is a contact-free method that can be carried out in the air and does not need to be dried after cleaning.

2, can completely remove the carbon and organic pollutants on the surface of objects.

3. Solvent-free volatilization and disposal of waste solvents.

4. Ensure high reliability and high yield of products.

5. The uniformity of surface cleaning treatment is consistent.

Note: Since light cleaning is to remove carbon and organic compounds on the surface of objects through photosensitive and oxidation reactions, the light cleaning method should not be used for surfaces prone to oxidation. It is only suitable for cleaning surface dirt, but not for cleaning inorganic dirt with more dirt.

UV cleaning is suitable for materials including ITO glass, optical glass, chromium plates, mask plates, and metal surfaces with oxide films that require precision cleaning. This process effectively removes various contaminants such as organic residues, human sebum, cosmetic oils, resin additives, polyimides, paraffin wax, rosin, lubricants, and residual photoresist.

Furthermore, UV light sources in LCD manufacturing demonstrate UV surface modification capabilities. Currently, they are primarily employed in film processing technologies to enhance inter-film adhesion between components such as ITO films and photosensitive adhesive layers, as well as TOP coatings and polyimide (PI) coatings. Before chip bonding in COG products, UV light cleaning is also required on bonding surfaces to improve adhesion strength and structural stability.

With the increasing quality requirements of LCD products, the LCD industry has been continuously improving the requirements for manufacturing process. In accordance with the demand of “if you want to do a good job, you must first sharpen your tools”, the UV light cleaning equipment, a key tool in LCD manufacturing, will continue to guarantee the quality of LCD products.