2025-12-26

In the era of information intelligence, whether in industrial instruments, medical equipment, vehicle dashboards, or household appliances, LCD screens serve as the core component of human-machine interaction. To meet the demands of different application scenarios, specific performance indicators, and personalized needs, custom LCD have become the mainstream. Therefore, the production cycle of LCD screens is a crucial factor for many customers during the procurement process. However, customers often find it difficult to understand the lead times of several weeks or even months for batch products. Here, we explain the production cycle of custom LCD products from three aspects: the product process flow, production management, and non-standard raw materials.

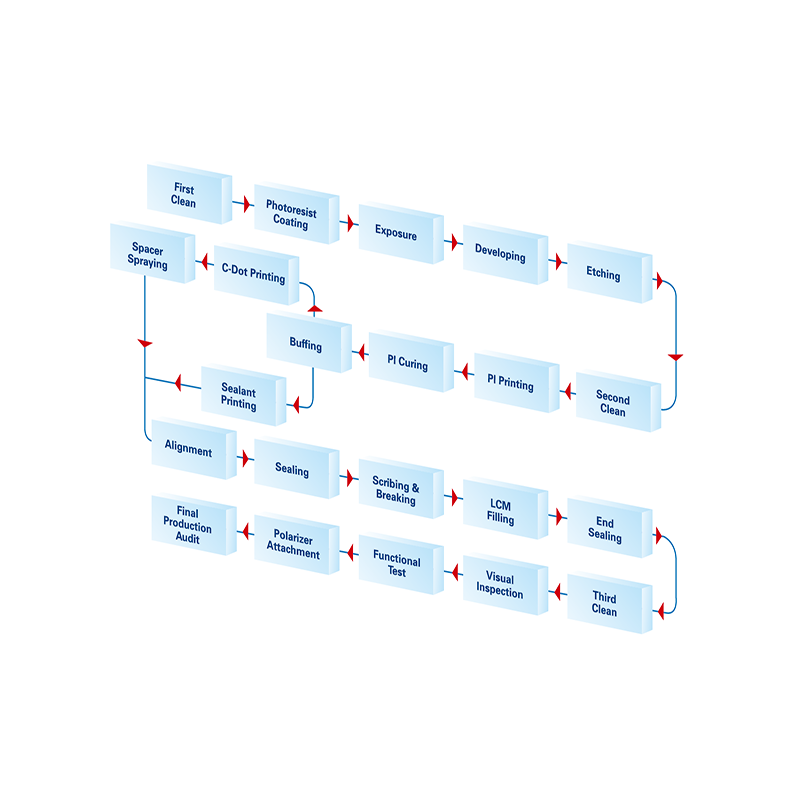

Process Flow of LCD Products

The production of LCD products begins with the input of ITO glass and ends with the Final Production Audit process. It involves a total of 22 main processes and 3–5 auxiliary processes. Before the alignment process, production follows a streamlined assembly line, involving steps such as photoresist and PI coating with temperature-controlled curing. The subsequent processes rely on automated equipment, involving equipment calibration and raw material segmentation. This results in longer production times and lower efficiency for small-batch orders. Unlike mechanical processing, producing 100 pieces or 1,000 pieces of LCD products takes almost the same amount of time, as all production processes must be completed. Additionally, certain products require extra special treatments (such as ultra-small size PIN installation, multiple photolithography steps, special-shaped processing, multi-color screen printing, freezing tests, etc.), which also extend the production cycle.

Production Management of LCD Products

Different types of LCD products require different raw materials. Switching production lines to produce different product types results in significant raw material wastage and consumes considerable time for adjusting equipment parameters. To improve production efficiency and raw material utilization, production management schedules production plans based on the types of products ordered.

Non-Standard Raw Materials

The main raw materials for LCD products are divided into standard specifications and non-standard specifications. Non-standard raw materials (such as special-shaped PINs, custom polarizers, etc.) are difficult to share with other products and cannot be kept as regular inventory. They are typically procured based on order quantities, leading to extended production cycles for LCD products that require non-standard raw materials due to longer lead times for these materials.

In summary, the production cycle for custom LCD batch products generally ranges from 30 to 40 days. For products requiring non-standard raw materials, the lead time may exceed two months.