2025-05-30

Mastering Quality Concepts to Promote High-Quality Development of Enterprises

In order to help employees and partners better understand the quality management system and enhance the quality awareness of all employees, we have compiled popular science knowledge about common quality terminology in the workplace, covering core content such as quality control, quality assurance, and continuous improvement. Whether you are a production worker, manager, purchaser, or employee in the marketing and sales department, this knowledge will play a role in your daily work.

I. Basic Concepts of Quality Management

Quality

Definition: The ability of a product or service to meet explicit or implicit requirements.

Key Points: It involves not only “conformity” but also “suitability.”

Quality Control

Definition: Monitoring the production process through technical means to ensure products meet standards.

Application Scenarios: Sampling inspections on production lines, real-time monitoring of equipment parameters.

Quality Assurance

Definition: Preventing quality issues through systematic management measures.

Differences: QC is “post-hoc inspection,” while QA is “preventive measures.”

II. Classic Management Methods and Tools

PDCA Cycle (Deming Cycle)

Significance: A continuous improvement model: Plan → Do → Check → Act (Plan → Execute → Inspect → Act).

Example: Through PDCA, a workshop reduced the defect rate of Segment display products from 0.12% to 0.015%.

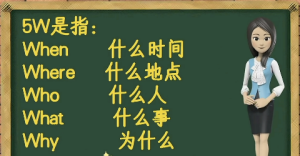

5W1H Analysis Method

Application: Identify the root cause of a problem by asking questions such as “Why?”, “What?”, “Where?”, “When?”, “Who?”, and “How?”.

Example: One of the VA LCDs produced by our company encountered an edge light leakage issue for the customer. Through the 5W method, we determined that the cause of the problem was a defect in the backlight structure provided by the customer. Our company assisted the customer in optimizing the backlight dimensions using VA LCD drawings, ultimately resolving the issue.

Poka-Yoke (Error-Proofing)

Definition: Developing equipment or processes to prevent human errors, such as USB interface designs that prevent incorrect connections.

Example: Our company’s TFT products were frequently connected to the wrong interfaces during customer use. We resolved this issue through a design that prevents incorrect connections.

III. International Quality Standards

ISO 9001

Core Values: A globally recognized quality management system standard emphasizing the “process approach” and “risk-based thinking.”

Latest Requirements: The 2015 version introduced new requirements for organizational environmental analysis and flexibility in responding to changes.

Example: ISO 9001 is often a prerequisite for customer access. Our company supplies 3.5-inch TFT screens and 4.3-inch TFT screens to European customers, which requires the factory to have an ISO 9001 system in place.

Six Sigma

Objective: To control defect rates below 3.4 per million, achieving breakthrough improvements through the DMAIC (Define, Measure, Analyze, Improve, Control) process.

IV. Customer-Centric Terminology

CS, Customer Satisfaction

Indicators: Product performance, delivery timeliness, after-sales service response speed, etc.

Example: Due to a sudden increase in orders from the end-customer market, we increased the number of night shifts for the production of HTN LCD and STN LCD models, thereby reducing the delivery time from 35 days to 25 days and meeting the customer’s requirements for quality and quantity.

VOC (Voice of the Customer)

Actual Meaning: Collect customer demand information through customer complaints and surveys to drive product upgrades.

Example: Starting from the second half of 2022, some customers began to frequently inquire about the viewing angle range of LCD screens and repeatedly mentioned product viewing angle issues in complaints. Through customer surveys, we began R&D on full-view LCDs in 2023 and officially started shipments in 2025. Currently, full-view LCDs have been successfully applied in aerospace industries, portable mobile device testing, and other fields.

V.

Kaizen

Core philosophy: Encourage employees to focus on details and improve efficiency through daily micro-innovations.

Zero Defects

Philosophy: Do it right the first time to avoid rework costs.

Conclusion

Mastering quality terminology is not only about accumulating knowledge but also the foundation for transforming theory into practical action.

As a professional manufacturer of liquid crystal displays and TFT displays, Dalian Eastern Display Co., Ltd. has accompanied its partners for 35 years, overcoming various challenges. Our company has always adhered to