2025-07-16

Introduction: LCD production facilities require exceptionally stringent cleanliness standards, particularly in the front-end manufacturing process (from glass substrate input to glass assembly). The workshop must maintain Class 100 cleanroom certification. Failure to meet these requirements would lead to a sharp increase in LCD screen defect rates, compromising both product stability and service life. Dongxian Electronics Co., Ltd. has consistently prioritized cleanroom control as the cornerstone of its LCD quality management system.

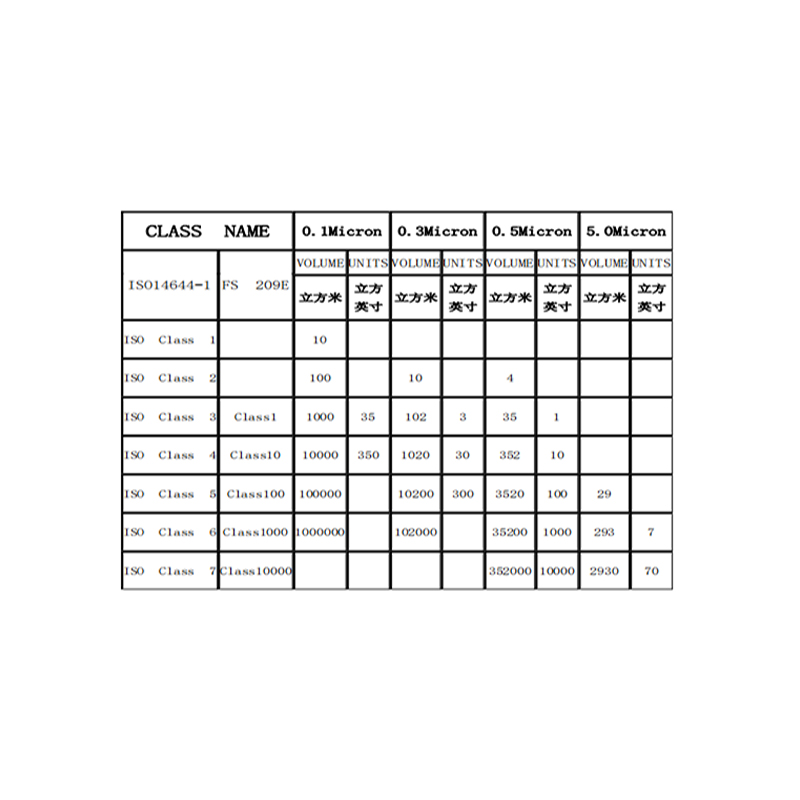

I. Cleanliness requirements

The cleanliness standard for a Class 100 cleanroom specifies that no more than 100 particles larger than 0.5μm should exist in every cubic foot (approximately 0.0283m³) of air. All surfaces within the facility—including walls, floors, ceilings, equipment, and tools—must remain dust-free, stain-resistant, and easy to clean.

II. Temperature and humidity requirements

In order to ensure the stable environment in the LCD workshop and meet the production requirements, the temperature in the 100-grade clean room should be controlled at 20-26℃, and the relative humidity should be controlled at 45%-65%RH. This requires a good air conditioning and ventilation system to ensure the stability and controllability of the workshop environment.

III. Microbial control

Microbial control is an important part of the operation of a clean room. The interior of the workshop should be disinfected regularly to prevent the growth of microorganisms. In addition, employees must undergo strict disinfection before entering the workshop, such as changing clean clothes, wearing masks and gloves.

IV. Dust particle control

Dust particles are the main factor affecting workshop cleanliness. Therefore, regular dust removal and cleaning should be carried out in the workshop to reduce the generation of dust particles. At the same time, employees should minimize unnecessary movement and operations when moving around in the workshop to reduce the generation and diffusion of dust particles.

V. Equipment layout and operation

The layout and operation mode of equipment have a significant impact on the cleanliness of the workshop. Equipment should be placed in a reasonable position to facilitate operation and maintenance, while avoiding the generation of too many dust particles. In addition, the operation of equipment should also be stable to reduce the impact on the workshop environment.

VI. Air handling system

The air treatment system, which serves as the core component of a Class 100 cleanroom, comprises high-efficiency filters, air circulation systems, and fresh air supply units. These systems require regular inspection and maintenance to ensure proper operation and effectiveness. Additionally, optimizing airflow velocity and direction within the workshop is essential to meet cleanliness requirements.

VII. Operating procedures and implementation

To ensure workshop cleanliness and production efficiency, it is essential to establish rigorous operational procedures and implementation standards. These protocols should cover employees’ daily conduct, equipment operation, environmental monitoring, and other aspects. Additionally, staff must receive relevant training and strictly adhere to the procedures to guarantee stable workshop operations and product quality.

VIII. Monitoring methods and standards

To evaluate the cleanliness and operational status of a workshop, regular monitoring and assessment are essential. Monitoring methods include particle counters and microbial testing. The results should be compared against workshop standards to promptly identify and resolve issues. Additionally, these findings should serve as a basis for improving workshop management and operations.

The above is the standard content of a 100-grade clean room. Dongxian Electronics will continue to pay attention to the purification of the workshop, improve the purification standard through precision equipment and scientific management system, and ensure the production of high-quality LCD products.

keyword :

LCD/ Class 100 clean room /LCD quality/high quality LCD/LCD workshop/ Class 100 clean room