This is a Liquid Crystal Display (LCD) with high anti-static (ESD) performance. Electrostatic discharge can damage electronic devices, particularly affecting LCD display quality in dry environments. Anti-static LCDs minimize the impact of static electricity on the screen through specialized designs, materials, and manufacturing processes, ensuring device reliability and longevity.

The Color Printing LCD Segment Display achieves monochrome, color, and gradient effects by applying ink to the surface of polarizers through screen printing or inkjet printing processes. It is widely used in industrial instruments, medical equipment, consumer electronics, and other fields.

Special-shaped metal PINs are non-standard shaped metal pins used in LCDs, typically designed to meet specific assembly requirements or adapt to particular usage environments.

A special-shaped LCD is a liquid crystal display that breaks away from the traditional rectangular shape, designed in circular, curved, triangular, or other irregular forms to meet specific needs in specialized fields.

FSTN LCD enhances viewing angle width and improves background color uniformity (compared to STN LCD) through the compensation film process. FSTN is suitable for multiplex dynamic driving and can support up to 320-multiplex dot matrix products, making it ideal for complex graphic displays.

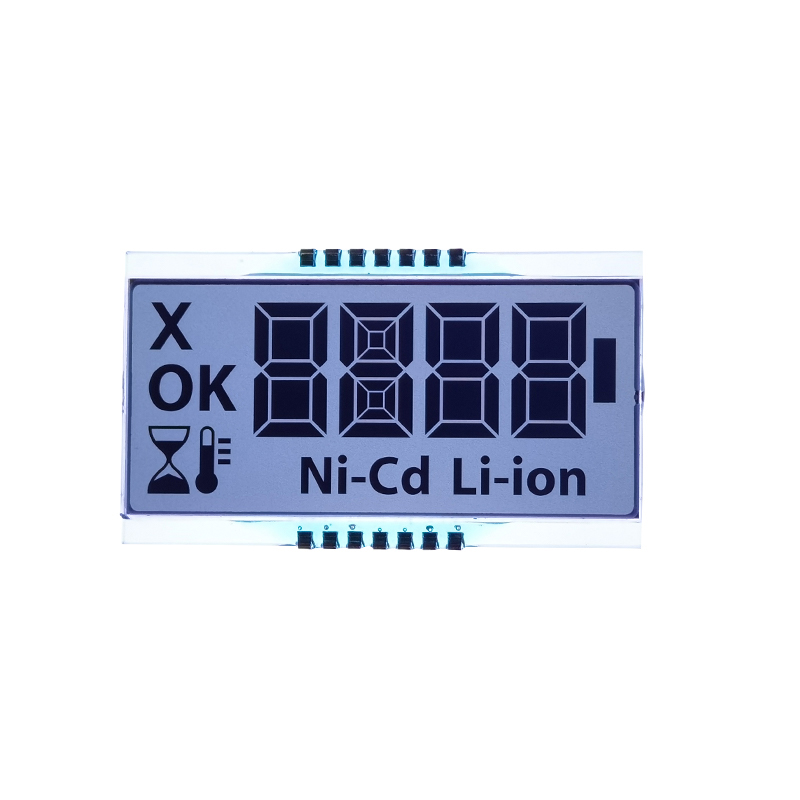

VA LCD segment displays feature a black background with white characters, offering high contrast, a wide operating temperature range, broad viewing angles, and fast response times. They can be combined with color silk printing or color filter films to achieve TFT-like colorful display effects and can also be used in conjunction with TFT screens.

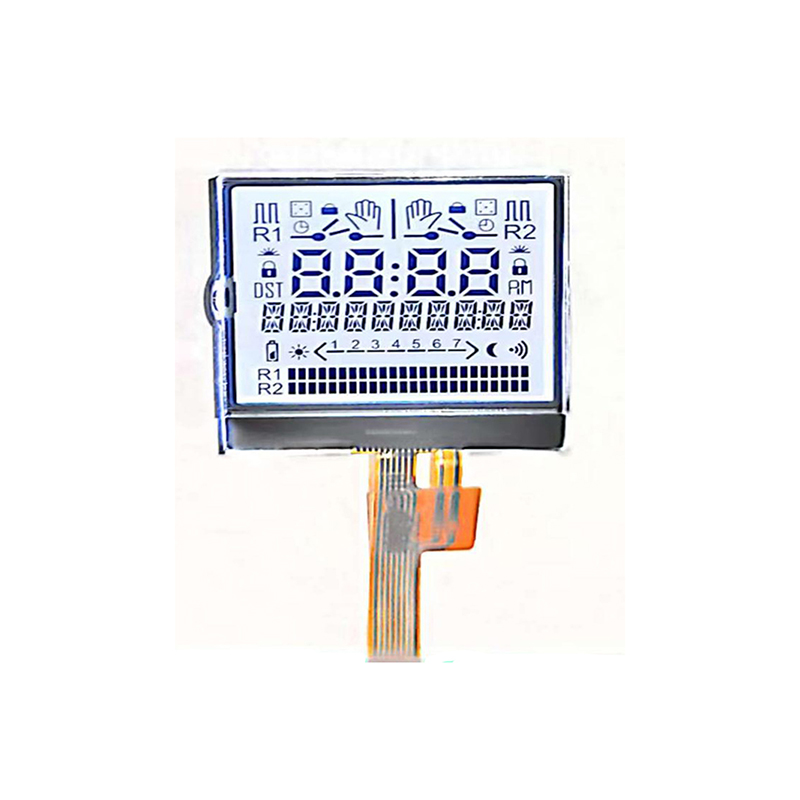

COG Segment LCD (Chip-on-Glass Segment Liquid Crystal Display) is a liquid crystal display technology where the driver chip (IC) is directly bonded onto the glass substrate. It features high integration, slim design, low power consumption, and low cost.

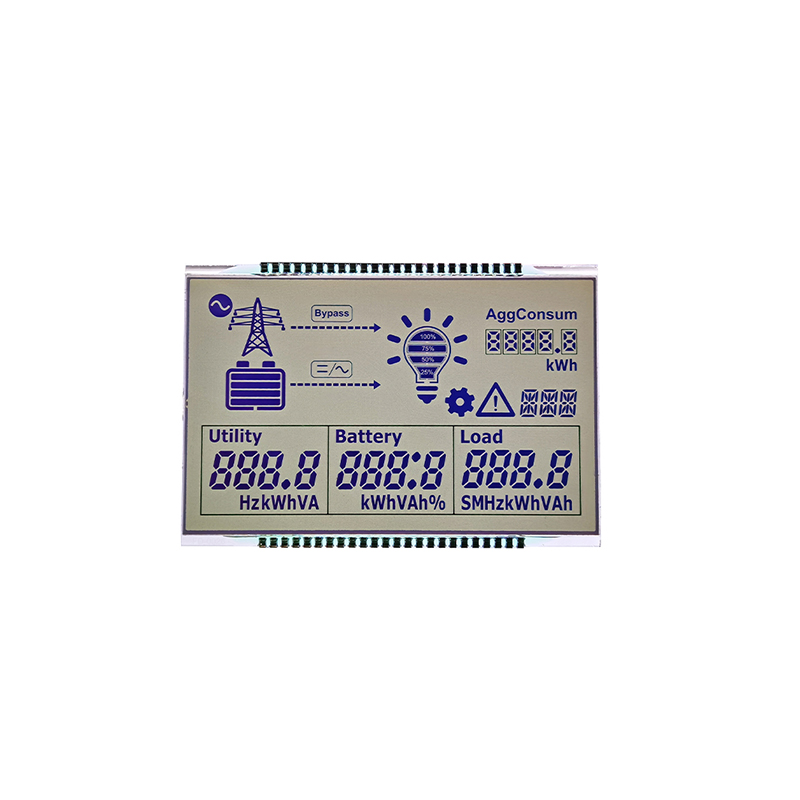

Segment LCD are widely used. For some product application scenarios, it is necessary to enhance display recognition and improve aesthetic appeal. By employing screen printing or the application of colored films onto the LCD surface, a monochrome LCD can achieve multi-color effects under low-cost conditions.

LCD segment displays are widely used, with some products deployed in extreme environments such as low temperature, high temperature, strong light, and high humidity. High-durability LCDs are designed to meet the demands of such harsh operating conditions.

Wide-view LCD Segment Display: LCD segment displays typically have a primary viewing angle. Outside this primary viewing angle, contrast ratio differs significantly. The width of the primary viewing angle varies depending on the product type and manufacturing process. The electrical characteristics and environmental parameters of wide-viewing angle products are consistent with those of standard LCD segment displays.

Backlit LCD segment display: LCD screens in environments with varying brightness levels typically require backlighting. Additionally, LCD products with screen printing and color film effects generally need backlighting support to achieve the desired screen printing results. Both backlighting and LCD screens can be customized for irregular shapes.

This customized segment code COG module features a TN LCD display integrated with driver chips using COG technology. The Transflective mode LCD panel is paired with LED backlighting, ensuring clear visibility in both bright and dim environments. It connects to the main MCU via a serial I2C interface through either a PIN or FPC connection. This LCD display module delivers low power consumption, a slim profile, excellent visual performance, stable operation, and cost-effective features.

A 30+ year professional manufacturer of high-quality and low-cost LCD display screens. Customized monochrome LCD screens, monochrome COG, COB modules, TFT modules and OLED modules for customers. Products are widely used in energy meters, blood glucose meters, blood pressure meters, flow meters, vehicle meters, household appliances, instruments, etc. LCD production capacity reaches 4000 sets/day, and LCD display modules 50K/day.