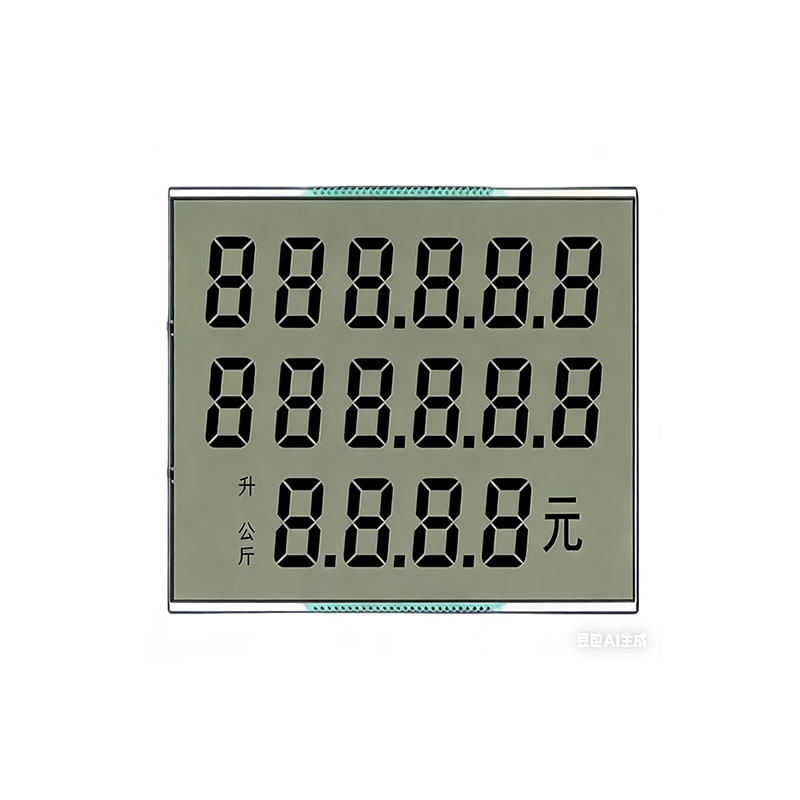

HTN LCD are widely used in various types of dispensing equipment, includingLNG 、dispenserfuel dispensers、special fluid dispensers、 self-sustaining pump dispensers、submersible pump dispensers、 self-service dispensers、and pre-set dispensers. Segment displays provide an intelligent presentation of core fueling information areas, status and prompt zones, and operator interfaces. For a fuel dispenser, an LCD is far more than just a simple “digital display”—it serves as a central interactive hub connecting the gas station, customers, payment systems, and backend management. It transforms a mechanical fluid-dispensing process into a digitized, information-enabled, and interactive modern commercial service environment.

As a key display component in smart electricity meters, the LCD is a high-performance, multi-level display solution. It is widely used in devices such as single-phase remote fee-controlled smart meters, three-phase multifunctional meters, and bidirectional metering smart meters. This display product supports hierarchical information presentation at the user, data, and management levels. It not only allows end-users to intuitively access electricity consumption data but also enables maintenance personnel to conduct in-depth data queries and system management. As the critical human-machine interface of the meter, the LCD serves not only as a window for information display but also as an important carrier reflecting the meter’s measurement accuracy, real-time communication data, and core functionalities. With its high contrast, wide viewing angle, and low power consumption, it ensures clear and stable content visibility under various lighting conditions. This contributes to a user experience where “information is clear to users and accessible for maintenance,” thereby significantly enhancing the practicality and reliability of smart electricity meters.

VA LCD products are widely used in outdoor portable power solutions such as portable energy storage systems, household energy storage units, and RV power systems. The LCD screen digitally and accurately displays real-time parameters including power levels and wattage, interface status, safety alerts, charge-discharge management, and power consumption analysis. It serves as a key component in outdoor portable power products for visually presenting functions such as electricity usage planning, operational status, fault warnings, and power distribution. Furthermore, compared to TFT products, LCD segment displays offer significant cost advantages. The black background of VA LCDs also effectively supports the visually integrated design of portable power products.

STN LCD are widely used in detection instruments, display instruments, and regulation (control) instruments. They can meet the industrial instruments’ requirements for high precision, high reliability, and intelligence. At the same time, STN dot matrix displays can accommodate the needs of complex display content, such as showing adjustment parameters, setting alarms, and outputting control signals. STN segment displays are capable of multiplex drive and offer a wide viewing angle range. Paired with a 10mm-thick glass cover, they can be adapted for explosion-proof, dust-proof, and contamination-resistant environments, with an optional integrated touch function.

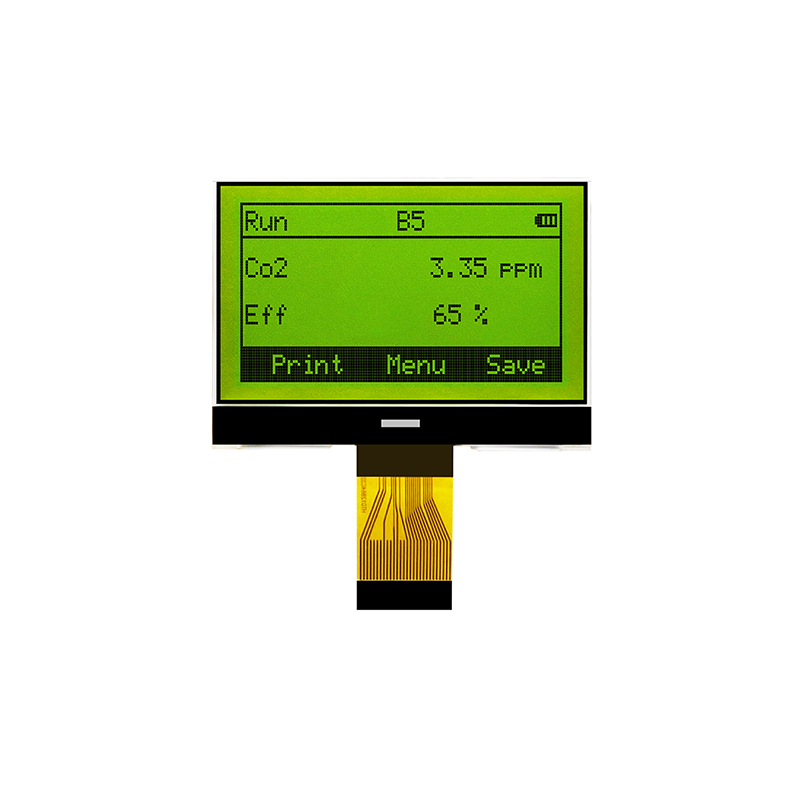

The COG LCD product is widely used in differential pressure flowmeters, positive displacement flowmeters, variable area flowmeters (rotameters), turbine flowmeters, electromagnetic flowmeters, vortex flowmeters, ultrasonic flowmeters, mass flowmeters, volumetric flowmeters, and more. Its dot matrix display can present information such as instantaneous flow rate, total accumulated flow, operational status indicators, engineering units, conductivity/empty pipe alarms, frequency/signal strength, temperature and density, speed of sound, and time of flight difference, in multiple languages as well as digitally. It ensures the accurate and reliable display of measurement data from the instrumentation.

The Negative LCD series is widely used in elevator applications such as floor indicator panels, hall call display panels, car operation panels, LCD information panels, horizontal display panels, and monochrome LCD modules. Among these, the three most representative display modes are white characters on a blue background, white characters on a black background, and colored characters on a black background. The LCD segment display is employed to show the current floor number, indicate the direction of elevator movement, confirm selected floors, display overload warnings, provide arrival notifications, and respond to passenger calls by indicating operational statuses such as “Up,” “Down,” or “Stopping.” Additionally, touch-sensitive functionality can be integrated to meet human-machine interaction needs during elevator operation.

VA LCD products are widely used in industrial alarm instruments such as multi-channel alarm meters, single-channel digital display alarm meters, status/process indicators, and dedicated gas detection alarm meters. The LCD screens digitally display real-time measurement values (temperature, pressure, etc.), alarm setpoints, analog displays (percentage), channel numbers, alarm status indications, gas concentration values (e.g., %LEL), and provide precise display of single-point parameters and threshold alarms. This enables the informational representation of instrument functions for monitoring production process parameters and ensuring personal and property safety.

Eastern Display manufactures various types of character dot matrix LCD modules and graphic dot matrix LCD modules. The display modes include Yellow-Green STN, Blue-White STN, and Gray-Black FSTN, among others. The production processes incorporate COB technology and COG technology. Paired with LED backlight of different colors, these modules can display various characters and graphics. They are easy to use, offer high reliability and cost-effectiveness, and provide diverse options, making them widely used in various types of power meters.

Portable energy storage devices. This product finds extensive applications ranging from the professional energy storage industry to everyday life. LCD screens are characterized by their light weight, strong environmental adaptability, low power consumption, high reliability, and low cost, making them typically the preferred solution for energy storage power supplies.

The 128×64 dot matrix LCD module is one of the most commonly used monochrome display products. Its display types include STN positive display, STN negative display, FSTN positive display, and FSTN negative display. It is paired with white backlight or other monochrome backlights, offering various display modes such as gray background with blue/black characters, yellow-green background with blue/black characters, and blue background with white characters. The product features high contrast and a wide viewing angle. The module contains a driver chip and connects to the main control MCU via an SPI interface or an 8-bit parallel LCD interface. It is simple to use, offers excellent display quality, and provides stable performance. It can display graphics and multiple lines of text, making it widely used in various arcade game machines.

Segment LCDs are widely used in fishing equipment, serving as the human-machine interface (HMI) display for devices such as smart fishing reels, fish finders, remote controls for bait boats, fishing scales, and fishing tackle boxes. Segment LCDs feature low cost, low power consumption, and high reliability, making them highly suitable for displaying critical parameters like numbers and fixed symbols.

Monochrome dot matrix LCDs in STN and FSTN types, with a resolution of 128×64 or higher, capable of displaying graphics and multiple lines of text. They are widely used in handheld portable terminals like POS machines. These products feature high contrast and wide viewing angles, available in various display modes such as gray background with blue-black characters, yellow-green background with blue-black characters, and blue background with white characters. Utilizing COG (Chip-on-Glass) manufacturing technology, the products are slim, lightweight, and feature low power consumption. The module includes a driver chip and connects to the main MCU via an SPI or I2C interface, offering simple operation, excellent display quality, and stable performance.

A 30+ year professional manufacturer of high-quality and low-cost LCD display screens. Customized monochrome LCD screens, monochrome COG, COB modules, TFT modules and OLED modules for customers. Products are widely used in energy meters, blood glucose meters, blood pressure meters, flow meters, vehicle meters, household appliances, instruments, etc. LCD production capacity reaches 4000 sets/day, and LCD display modules 50K/day.