Exiting a project that utilizes a 0.96 OLED display can involve a multitude of factors, from technological limitations to shifting project requirements. This comprehensive guide provides a structured approach to navigating this process effectively, considering various scenarios and offering practical solutions for manufacturers and developers. We’ll explore technical considerations, logistical challenges, and potential alternatives to help you make informed decisions.

Before exploring exit strategies, it's crucial to identify the precise reasons for needing to move away from a 0.96 OLED display. This clarity will inform the most appropriate course of action. Common reasons include:

The cost-effectiveness of a 0.96 OLED display can be a significant factor. If the budget is constrained, or if the display represents a disproportionately large portion of the overall product cost, exploring alternative display technologies becomes necessary. Consider factors like production volume and the possibility of negotiating better pricing with your current 0.96 OLED display supplier.

Sometimes, the inherent limitations of a 0.96 OLED display might necessitate an exit strategy. For instance, if the display's resolution, brightness, or viewing angle fails to meet evolving project needs, a superior technology might be required. Exploring higher-resolution displays or alternatives like LCDs with improved backlighting could be viable solutions.

Disruptions to the supply chain can force a project to reconsider its reliance on a specific display technology. If procuring sufficient quantities of the 0.96 OLED display becomes challenging or unreliable, securing alternative display components becomes crucial. Maintaining a robust and flexible supply chain is important for the longevity of any project. For reliable and high-quality display solutions, consider exploring options from reputable manufacturers such as Dalian Eastern Display Co., Ltd.

The need to exit a project involving a 0.96 OLED display doesn't necessarily signify project failure. It often presents an opportunity to leverage improved technologies. Here are some potential alternatives:

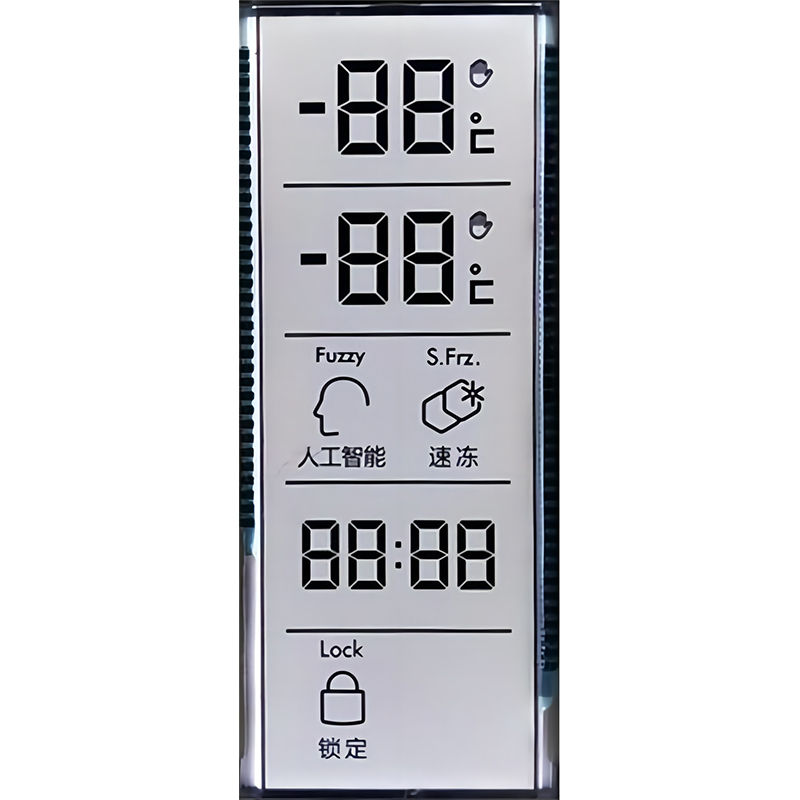

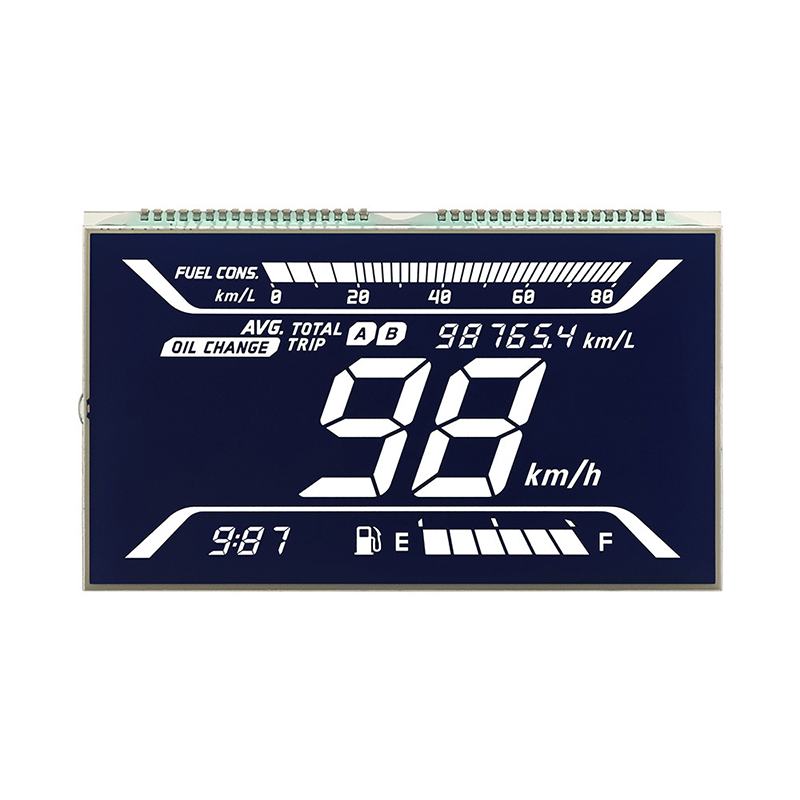

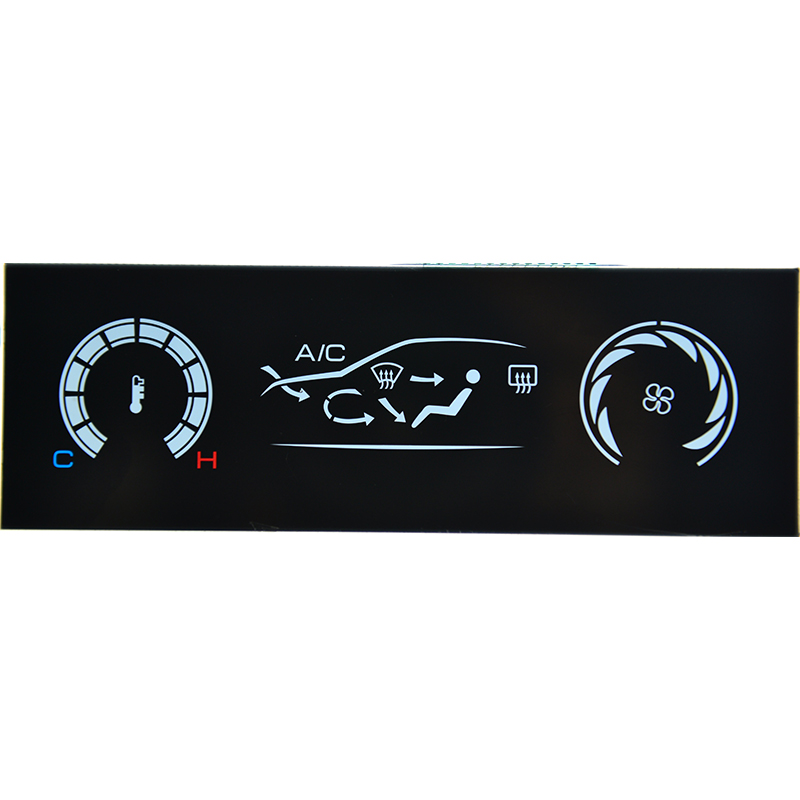

LCDs offer a cost-effective alternative to OLEDs, often providing sufficient performance for applications where high contrast ratios are not paramount. They can be a suitable replacement for a 0.96 OLED display, particularly in volume production where cost savings are crucial.

If the project's core functionality is dependent on OLED technology, exploring other screen sizes might be viable. A larger or slightly smaller OLED display could offer similar functionality with improved performance or cost-effectiveness.

Moving away from a 0.96 OLED display requires a methodical approach to ensure a smooth transition and minimal disruption. This includes:

Before fully committing to an alternative display, rigorous testing and validation are essential. The new display must meet the project's functional requirements in terms of performance, resolution, and compatibility.

Adapting existing software and hardware to accommodate the new display requires careful planning and execution. This may involve rewriting firmware, adjusting driver software, and even modifying the physical layout of the device.

A phased rollout can minimize risks associated with a complete switch to a new display technology. Gradually introducing the new display into production allows for troubleshooting and adjustments before a full-scale deployment.

Exiting a project using a 0.96 OLED display requires a thoughtful evaluation of various factors. By carefully analyzing the reasons for the exit, exploring suitable alternatives, and adopting a methodical transition strategy, developers and manufacturers can navigate this process effectively and maintain project success. Remember to prioritize thorough testing and validation at every stage of the transition to minimize disruptions and ensure the continued success of the project.