The demand for high-quality, high-refresh-rate displays continues to surge, driving innovation in display technology. At the forefront is the 120Hz E4 AMOLED display, a technology offering exceptional visual fidelity and responsiveness. This article provides a detailed overview of the manufacturing process behind these advanced displays, examining the various stages, technological considerations, and the leading companies involved in their production. Understanding the intricacies of 120Hz E4 AMOLED display factory operations allows for a better appreciation of the technology's capabilities and limitations.

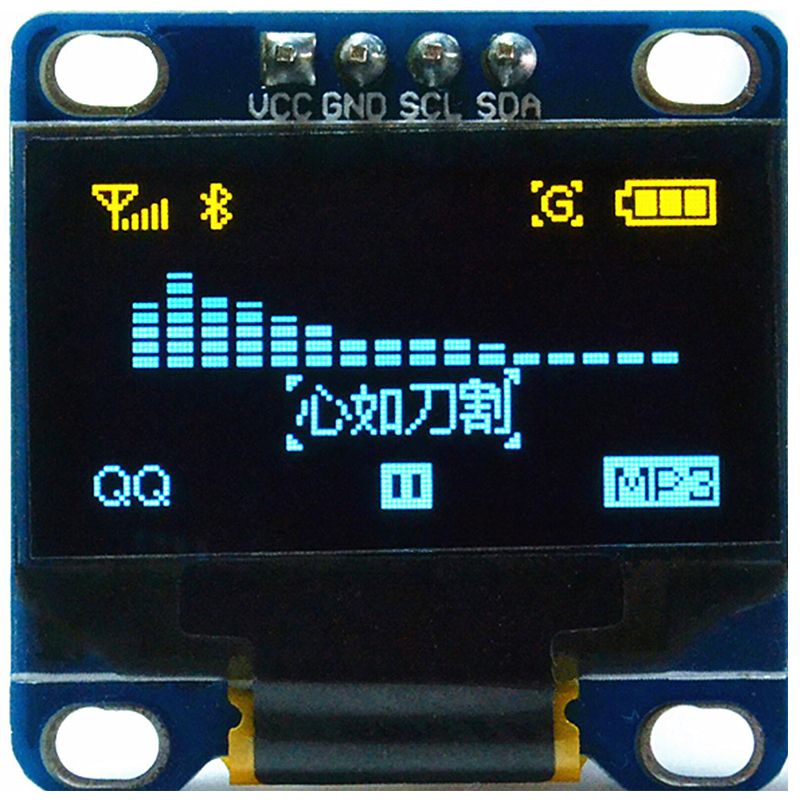

Before delving into the manufacturing process, it's crucial to understand the underlying technology. E4 AMOLED technology represents a significant advancement over previous AMOLED generations (like E3). Key improvements often include enhanced color accuracy, improved power efficiency, and higher brightness levels. The E4 designation reflects specific advancements in the underlying substrate and pixel structure, typically leading to thinner panels and improved performance. The implementation of a 120Hz refresh rate further elevates the visual experience, resulting in smoother scrolling and motion, particularly beneficial for gaming and video consumption.

The manufacturing of a 120Hz E4 AMOLED display is a complex and multi-stage process requiring highly specialized equipment and precision engineering. The process generally includes the following steps:

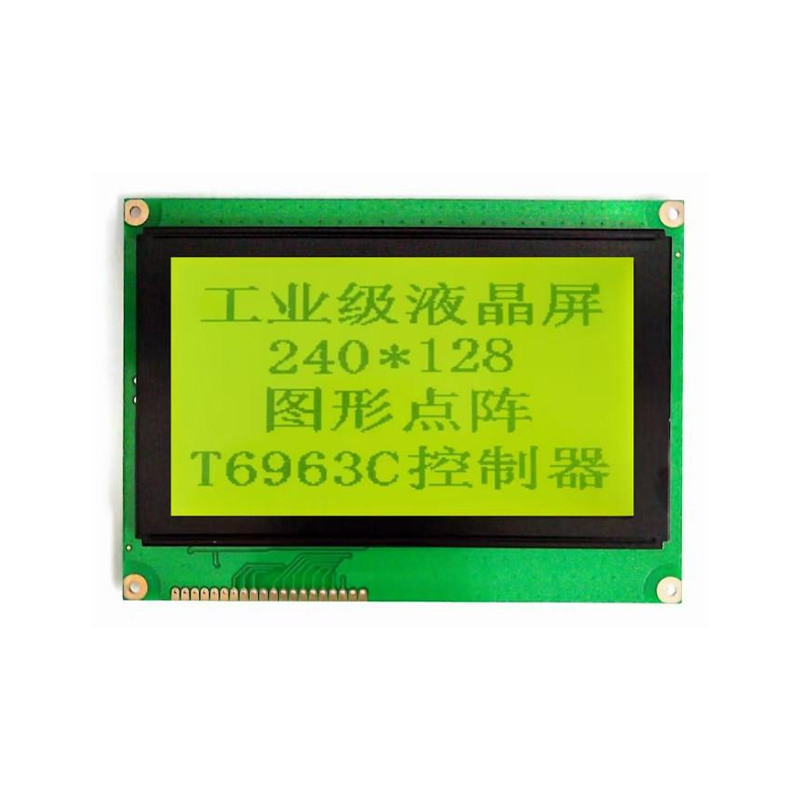

This stage involves preparing the substrate material (typically glass or plastic) and depositing thin-film transistors (TFTs) and other necessary layers. This process requires meticulous control of temperature and atmosphere to ensure the quality and uniformity of the deposited layers. The precise alignment and patterning of TFTs are crucial for achieving the high resolution and refresh rate of the final product.

The organic light-emitting diodes (OLEDs) are deposited onto the TFT layer. This is a critical stage, as the quality and performance of the OLEDs directly impact the display's color accuracy, brightness, and lifespan. The deposition process needs to be precise to create uniform layers, ensuring consistent pixel behavior across the entire display area. Precise control of the deposition process ensures minimal defects and high yield.

Once the organic layer is deposited, the display is encapsulated to protect it from moisture and oxygen, which can degrade the OLEDs. The encapsulation process typically involves sealing the display with a protective layer, often using advanced materials and techniques to maintain performance and longevity. The final assembly stage involves integrating the display panel into a complete module, including backlight, touch screen, and other necessary components.

Several companies play a significant role in the production and supply of 120Hz E4 AMOLED displays. These include leading display manufacturers, material suppliers, and equipment providers. While specific companies involved in individual processes often remain confidential due to proprietary reasons, major players in the AMOLED technology landscape are well-known. Research into these companies often reveals insights into the advancements and challenges in manufacturing these high-end displays.

Despite the advancements in 120Hz E4 AMOLED display technology, several challenges remain. These include maintaining consistent quality across large-scale production, reducing costs, and improving the lifespan of the displays. Future trends are expected to focus on further improving power efficiency, color accuracy, and brightness while exploring more sustainable and cost-effective manufacturing processes. Innovations in materials science and manufacturing techniques will play a critical role in shaping the future of this technology.

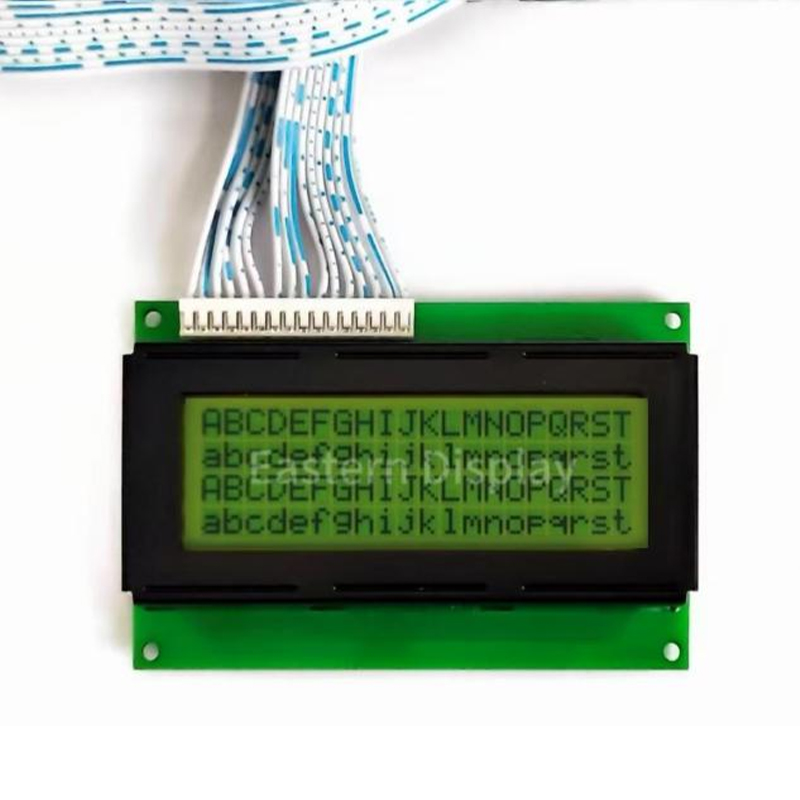

For further information on high-quality display solutions, you might want to explore the offerings at Dalian Eastern Display Co., Ltd. They are a prominent player in the display manufacturing industry.

| Feature | E3 AMOLED | E4 AMOLED |

|---|---|---|

| Power Consumption | Higher | Lower |

| Brightness | Lower | Higher |

| Color Accuracy | Good | Excellent |

1 Data comparisons are based on general industry trends and may vary depending on specific implementations.