This comprehensive guide explores the intricacies of the 12232 LCD factory market, providing insights into production processes, key players, and the technological advancements shaping this industry. We delve into the specifics of 12232 LCD displays, exploring their applications and future trends. This in-depth analysis is perfect for professionals seeking to navigate the complexities of the LCD manufacturing sector.

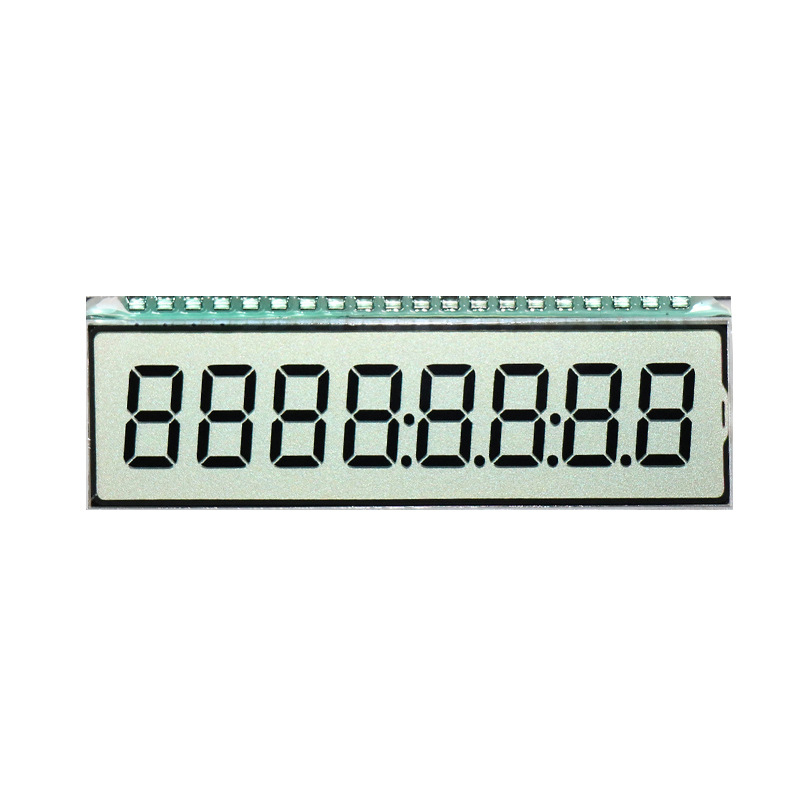

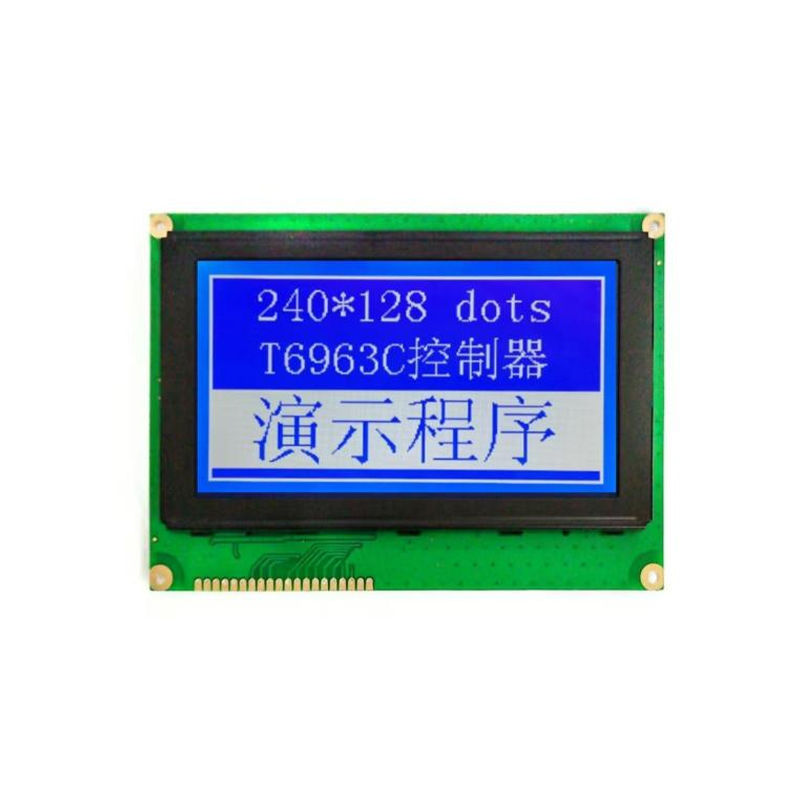

12232 LCD factories produce 12232 LCD displays, a specific type of liquid crystal display characterized by its resolution and size. These displays are commonly utilized in various applications, from simple electronic devices to more complex systems. Understanding the unique characteristics of 12232 LCDs is crucial for anyone involved in sourcing or integrating these components into their products.

The production of 12232 LCDs is a complex, multi-stage process. This involves various steps, including substrate preparation, pixel formation, polarizer application, and final assembly. Each stage requires precise control and adherence to stringent quality standards to ensure the final product meets performance expectations. Efficient production relies on specialized equipment and highly skilled labor.

The global market for 12232 LCD factories is highly competitive, with numerous companies vying for market share. These companies range from large multinational corporations to smaller, specialized manufacturers. Understanding the competitive landscape is essential for strategic decision-making.

While a complete list requires extensive research, it's important to note that many manufacturers produce LCDs with similar specifications. Identifying your specific needs and contacting manufacturers directly is crucial for securing the right product. For example, consider exploring the capabilities of companies like Dalian Eastern Display Co., Ltd., a reputable player in the LCD manufacturing sector.

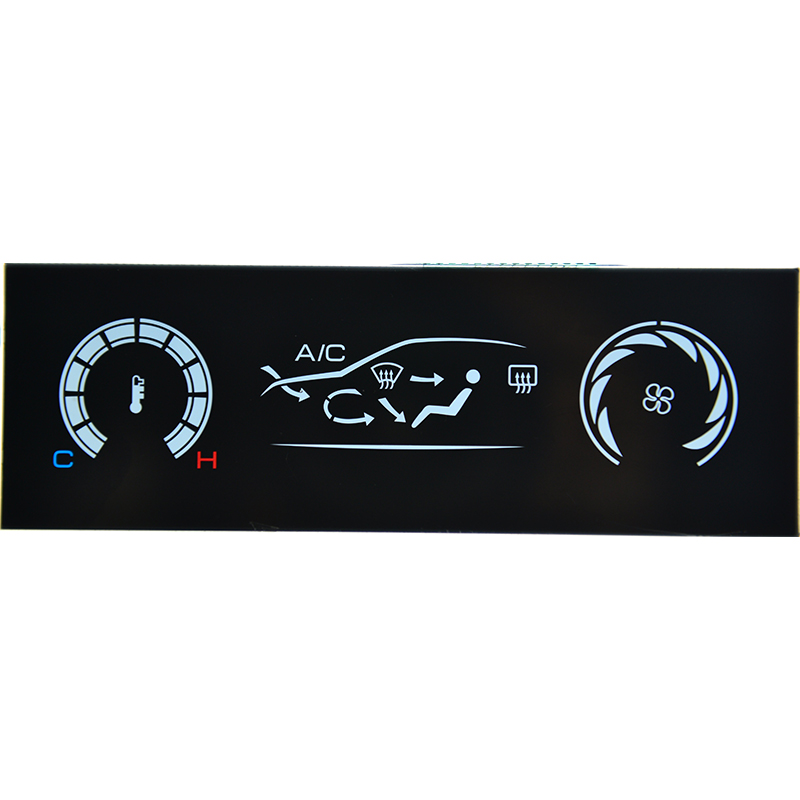

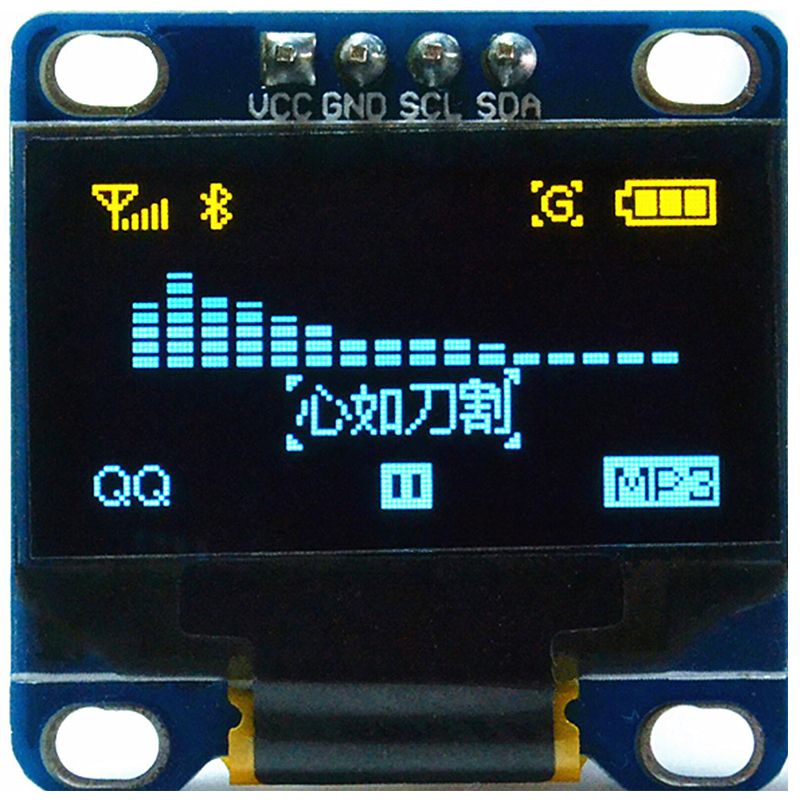

12232 LCD displays find applications across a wide range of industries. Their relatively compact size and versatile nature make them ideal for use in:

The 12232 LCD factory industry is continuously evolving. Key trends include:

Selecting a suitable 12232 LCD factory requires careful consideration of several factors, including production capacity, quality control measures, and pricing strategies. Thorough due diligence is essential to ensure a reliable and cost-effective supply chain.

| Factor | Considerations |

|---|---|

| Production Capacity | Ensure the factory can meet your order volume. |

| Quality Control | Verify their quality assurance processes. |

| Pricing | Compare prices from multiple suppliers. |

| Lead Times | Inquire about their production timelines. |

Remember to conduct thorough research before committing to any 12232 LCD factory. Your success hinges on selecting a reliable and capable partner.