This comprehensive guide helps you navigate the world of 16:2 LCD display factories, providing insights into factors to consider when selecting a supplier. Learn about different display types, quality control, and crucial considerations for successful sourcing. We’ll explore key specifications, potential challenges, and best practices for ensuring a smooth and efficient process.

16:2 LCD displays refer to liquid crystal displays with an aspect ratio of 16:2, indicating a wider than typical screen. While less common than standard ratios like 16:9 or 4:3, this aspect ratio finds applications in specialized niches. The specific uses often dictate the necessary features and manufacturing processes.

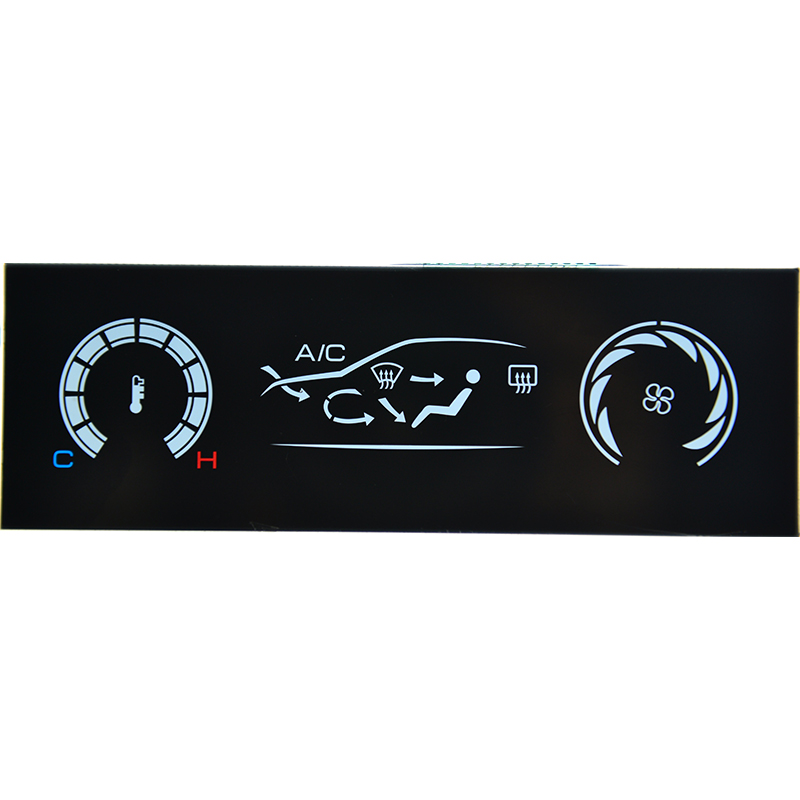

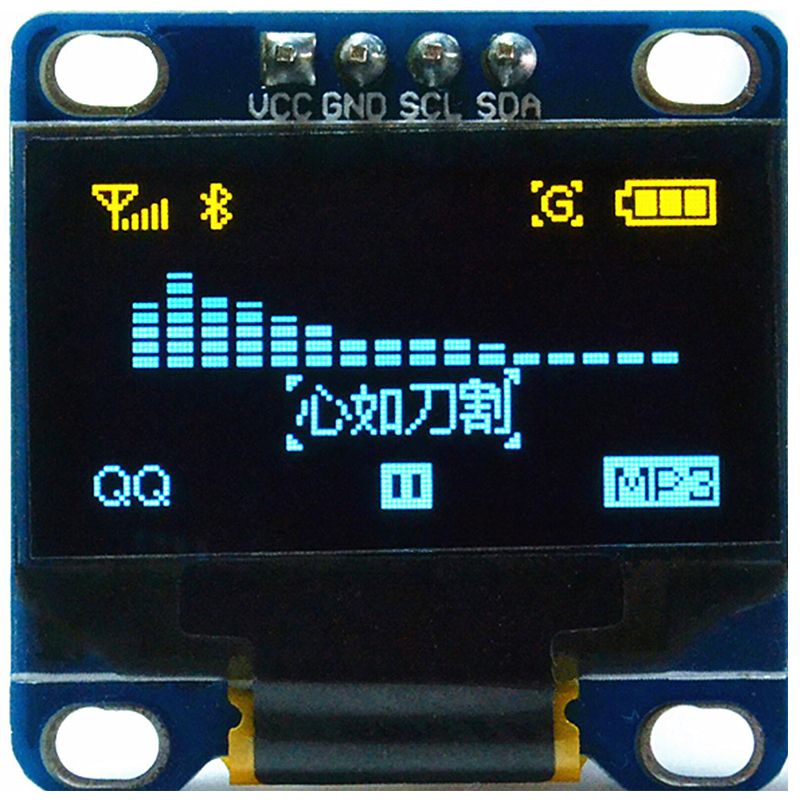

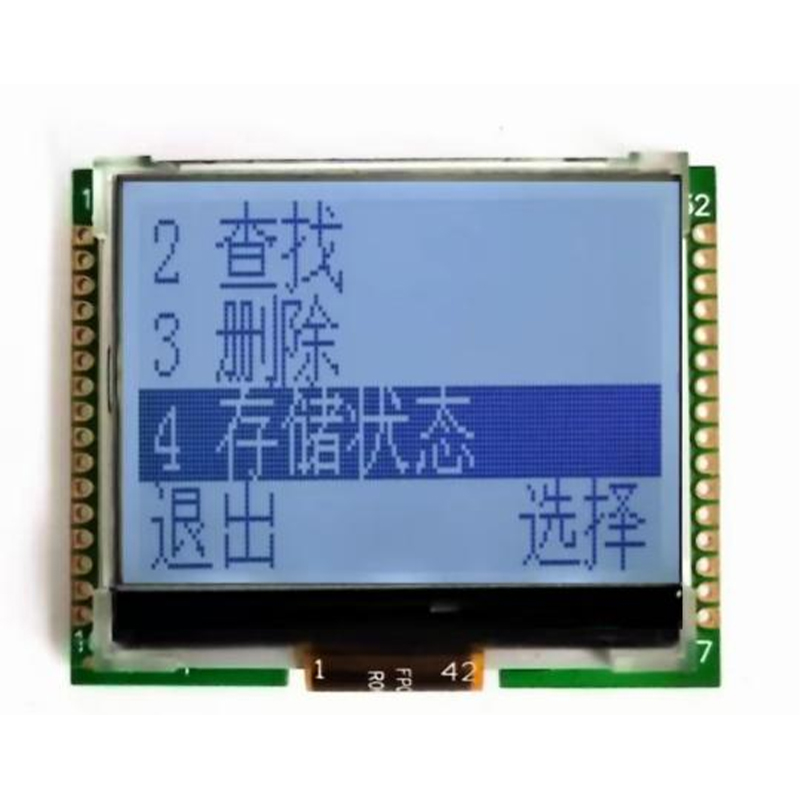

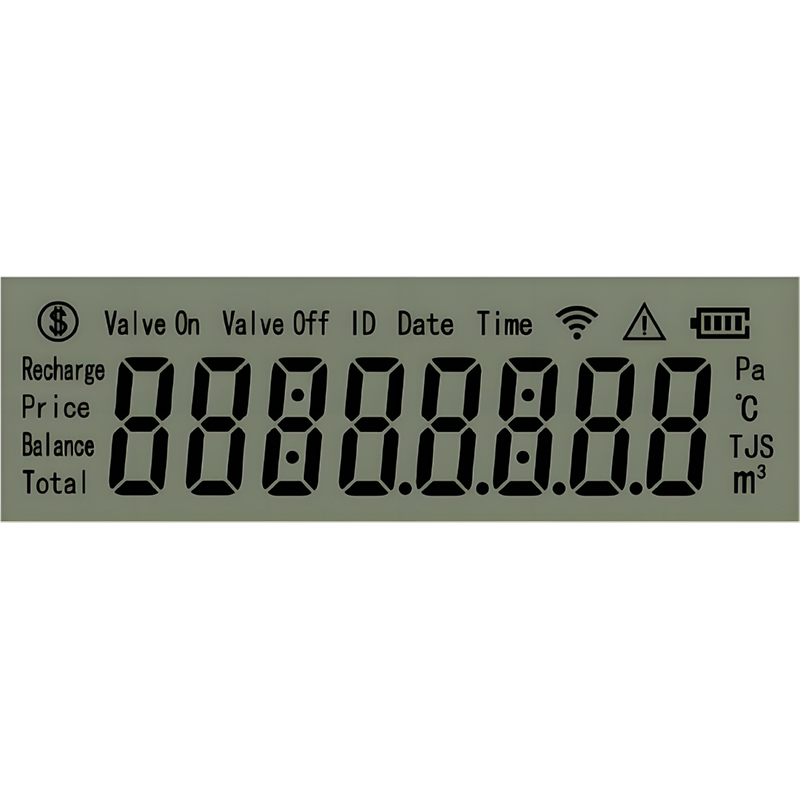

The type of 16:2 LCD display needed depends heavily on the application. Consider factors like resolution, brightness, contrast ratio, response time, and viewing angle. For example, a display for industrial applications might prioritize durability and readability in direct sunlight, whereas a display for a specialized consumer product may need higher resolution and color accuracy. Many manufacturers offer customization options to cater to diverse requirements.

Selecting a reliable 16:2 LCD display factory is crucial for the success of your project. Consider these key aspects:

Thorough due diligence is essential. Verify the factory's legitimacy, conduct background checks, and consider visiting the factory for an on-site assessment if possible. Reading online reviews and seeking recommendations can also provide valuable insights.

Various online platforms list manufacturers of LCD displays. However, always carefully vet potential suppliers before engaging them.

Attending trade shows and industry events focused on electronics manufacturing provides opportunities to network with potential suppliers, compare products, and assess their capabilities directly.

Maintain open and consistent communication throughout the entire process. Clearly define your requirements, specifications, and expectations to minimize misunderstandings and delays.

Implement rigorous quality assurance and testing procedures to ensure the displays meet your standards. Regular communication and collaboration with the factory are crucial for addressing any issues that may arise.

For high-quality 16:2 LCD displays and expert manufacturing services, consider exploring options from reputable suppliers. A thorough research process, including supplier vetting and contract negotiation, is vital for successful procurement. Remember to factor in lead times and maintain open communication with your chosen factory.

While this guide offers valuable insights, always conduct your own thorough research and due diligence before selecting a 16:2 LCD display factory. The success of your project hinges on the quality of your chosen partner.

| Aspect | Considerations |

|---|---|

| Quality Control | ISO certifications, defect rates, sample testing |

| Lead Times | Production schedule, delivery reliability |

| Pricing | Compare quotes from multiple suppliers, payment terms |

For a wide range of LCD display solutions, consider exploring Dalian Eastern Display Co., Ltd. They offer comprehensive services and expertise in the LCD display industry.