This comprehensive guide helps you understand and resolve common issues with your 1602 LCD screen, focusing on exit codes and troubleshooting steps. We'll cover various scenarios, providing practical solutions and resources to get your display working optimally. Learn how to identify problems, interpret error messages, and implement effective fixes.

The HD44780 controller, commonly used in 1602 LCD screens, doesn't directly provide exit codes in the traditional sense. Instead, issues manifest as display malfunctions like blank screens, garbled text, or incorrect character displays. These problems often stem from incorrect initialization, wiring errors, or software glitches.

Let's explore some typical problems encountered with 1602 LCD screens:

A systematic approach is crucial for resolving issues with your 1602 LCD screen. Follow these steps:

Carefully inspect all connections between your microcontroller (e.g., Arduino, Raspberry Pi), the LCD screen, and the power supply. Ensure secure connections to the correct pins, paying close attention to the VSS, VDD, and contrast pins. Loose connections are a frequent culprit.

The 1602 LCD screen requires a stable power supply, typically 5V DC. Use a multimeter to verify that the correct voltage is reaching the LCD. Insufficient power can lead to various display problems.

The contrast adjustment potentiometer (usually a small dial on the back of the LCD) affects the screen's visibility. Adjust this potentiometer to find the optimal contrast level. Too little or too much contrast can cause display problems.

If you're using a microcontroller, carefully review your code for any errors in the initialization sequence or data transmission. Errors in the code are a common cause of 1602 LCD screen malfunctions. Many tutorials and examples are available online to aid in the correct initialization of the screen.

If possible, test the 1602 LCD screen with a known-good microcontroller and program to rule out hardware failures. This helps isolate whether the problem lies with the LCD itself or your setup.

For further assistance and detailed information, refer to the datasheets provided by manufacturers of your 1602 LCD screen. These datasheets contain comprehensive information on specifications, pinouts, and operational details. Additionally, online forums and communities dedicated to electronics and embedded systems offer valuable support.

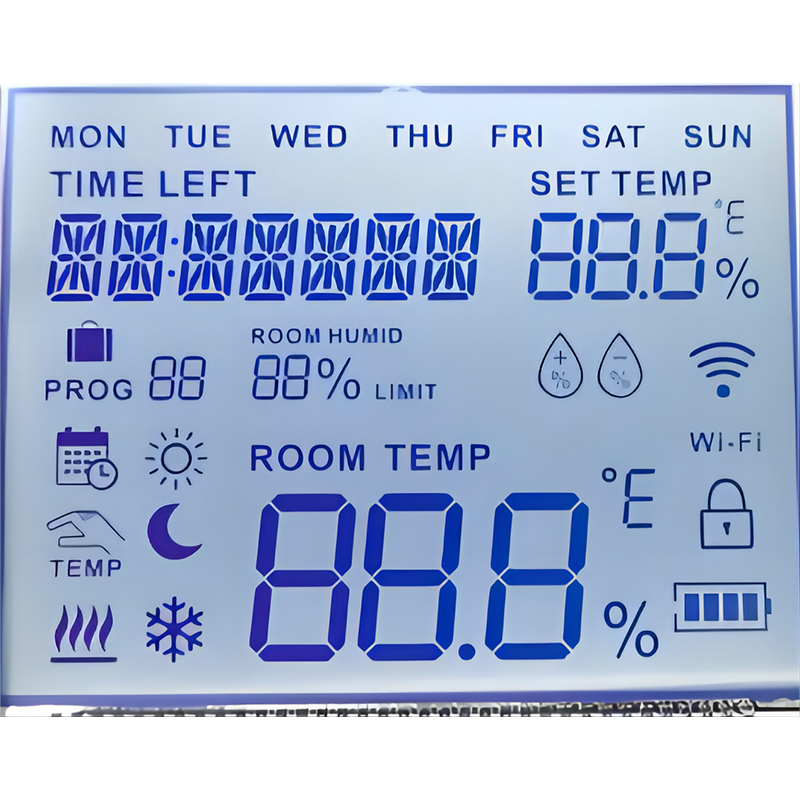

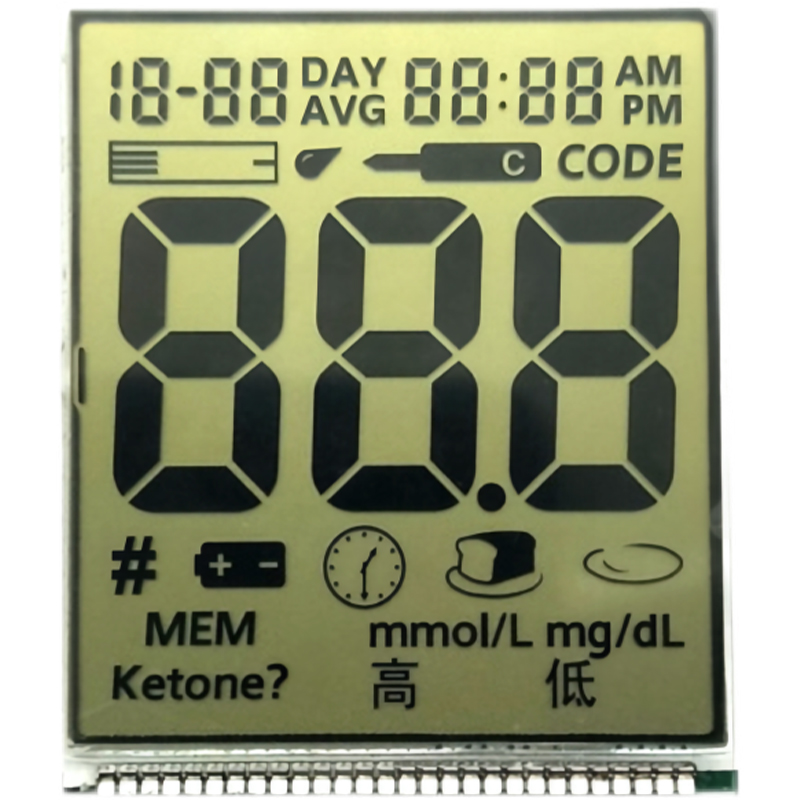

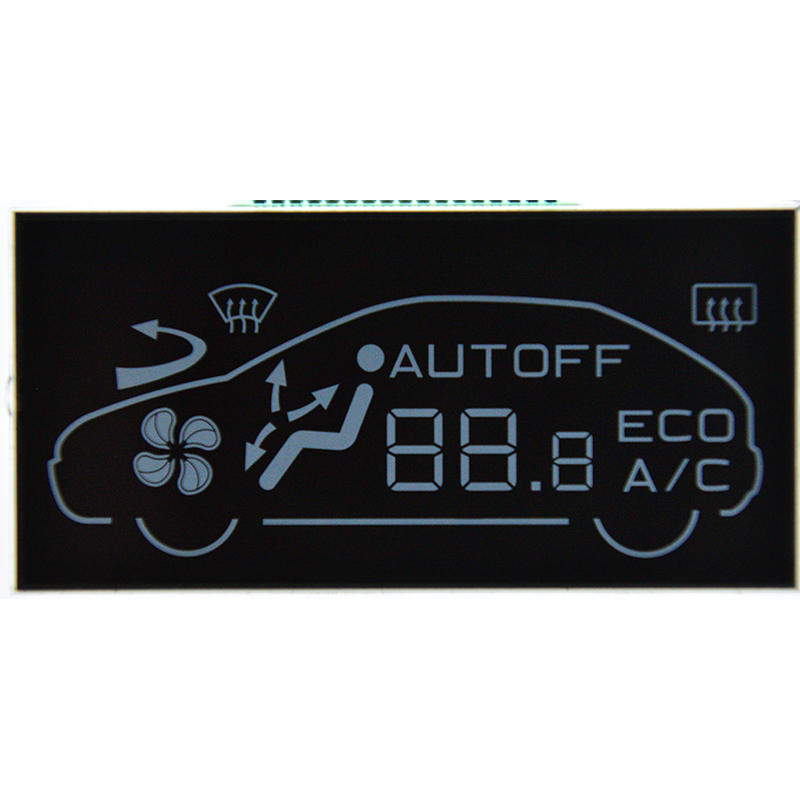

Consider sourcing high-quality 1602 LCD screens from reputable suppliers like Dalian Eastern Display Co., Ltd. to minimize potential issues. They offer a range of LCD screens and related products for various applications.

Successfully troubleshooting your 1602 LCD screen requires a methodical approach, combining careful hardware inspection with thorough code review. By systematically checking connections, power supply, contrast, and code, you can effectively diagnose and resolve most display problems. Remember to always consult manufacturer datasheets and online resources for further assistance.