This comprehensive guide helps you navigate the world of 32 LCD factories, providing insights into factors to consider when selecting a manufacturer for your project. We’ll explore different types of displays, crucial specifications, and key considerations for successful collaboration.

Understanding the different panel technologies available is crucial in selecting the right 32 LCD factory. Common technologies include IPS (In-Plane Switching), TN (Twisted Nematic), and VA (Vertical Alignment). Each offers a unique balance of color accuracy, response time, viewing angles, and contrast ratio. For example, IPS panels are known for their wide viewing angles and accurate color reproduction, making them ideal for applications requiring high visual fidelity. TN panels, on the other hand, offer faster response times but often sacrifice color accuracy and viewing angles. VA panels sit somewhere in between, balancing contrast ratio and viewing angles.

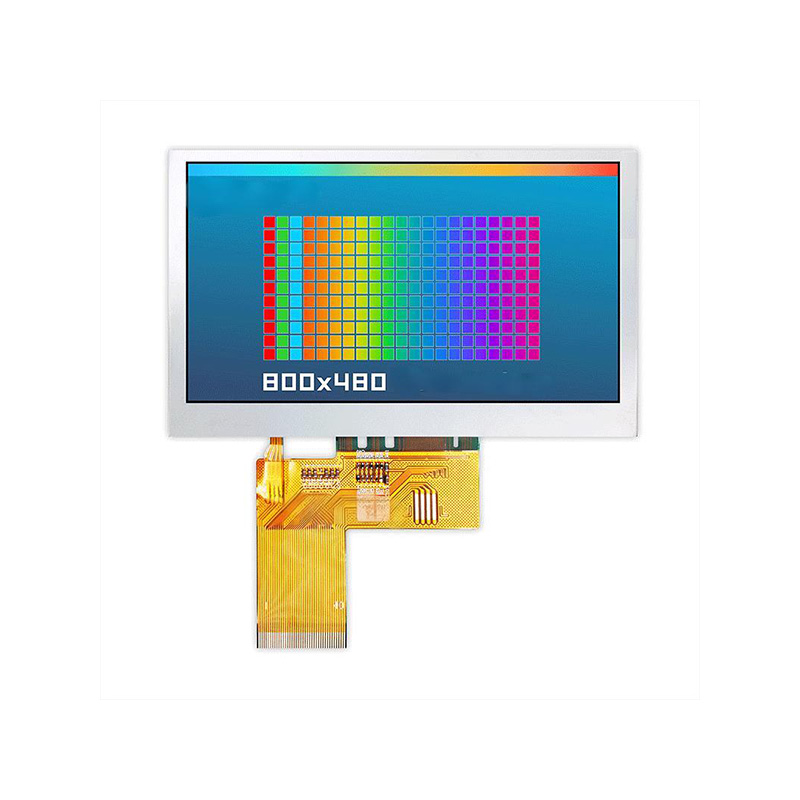

The resolution of a 32 LCD screen, measured in pixels (e.g., 1920x1080, 2560x1440), directly impacts image sharpness and detail. Higher resolution generally means a sharper image, but it also increases the manufacturing complexity and cost. Pixel density (pixels per inch, or PPI) is another crucial factor, influencing the perceived sharpness from a viewing distance.

Brightness (measured in cd/m2) affects visibility in different ambient lighting conditions. Higher brightness is generally preferred for use in brightly lit environments. Contrast ratio represents the difference between the brightest white and the darkest black a display can produce, contributing to image depth and clarity. Response time (measured in milliseconds) dictates how quickly the pixels change color, crucial for applications like gaming where fast transitions are essential. When choosing your 32 LCD factory, carefully consider these specifications to ensure they align with your application’s requirements.

Before partnering with a 32 LCD factory, thoroughly vet their manufacturing capabilities. Look for certifications, quality control processes, and a proven track record. Investigate their production capacity to ensure they can meet your volume requirements. Consider visiting the facility if possible, to directly assess their operational standards and equipment.

Obtain detailed quotes from multiple 32 LCD factories, comparing not only the price per unit but also the total cost, including shipping, customs duties, and potential additional fees. Inquire about lead times to understand how long it will take to receive your order. Consider the potential impact of delays on your project timeline.

Effective communication is crucial for a successful collaboration. Choose a 32 LCD factory with responsive and clear communication channels. Investigate their after-sales support services, including warranty provisions and technical assistance. A strong communication framework can help mitigate potential issues and streamline the entire process.

While we cannot provide an exhaustive list, researching potential manufacturers online is essential. Many companies specialize in producing various sizes and types of LCD screens. Remember to carefully check reviews and ratings before making any commitments.

For high-quality 32 LCD panels and manufacturing solutions, consider exploring companies like Dalian Eastern Display Co., Ltd. You can learn more by visiting their website: https://www.ed-lcd.com/

Choosing the right 32 LCD factory requires meticulous research and careful consideration of several key factors. By carefully evaluating the manufacturer's capabilities, understanding your specific needs, and prioritizing communication, you can ensure a successful partnership and achieve your project goals.