This article explores the complex world of acer lcd monitor factory production, examining the various stages involved, key players, and considerations for businesses seeking reliable sources for these displays. We'll delve into the manufacturing process, discuss quality control, and highlight the importance of choosing the right supplier for your needs. Learn about the different types of LCD monitors produced, the technological advancements shaping the industry, and how to navigate the complexities of sourcing these essential components.

The production of acer lcd monitor factory products begins with sourcing high-quality raw materials. This includes components like LCD panels, backlight units (BLUs), circuit boards, and casings. Reputable suppliers ensure consistent quality and reliability throughout the manufacturing process. Strict quality checks are implemented at this initial stage to minimize defects later down the line. Major manufacturers often have established partnerships with suppliers to guarantee a continuous and reliable flow of materials.

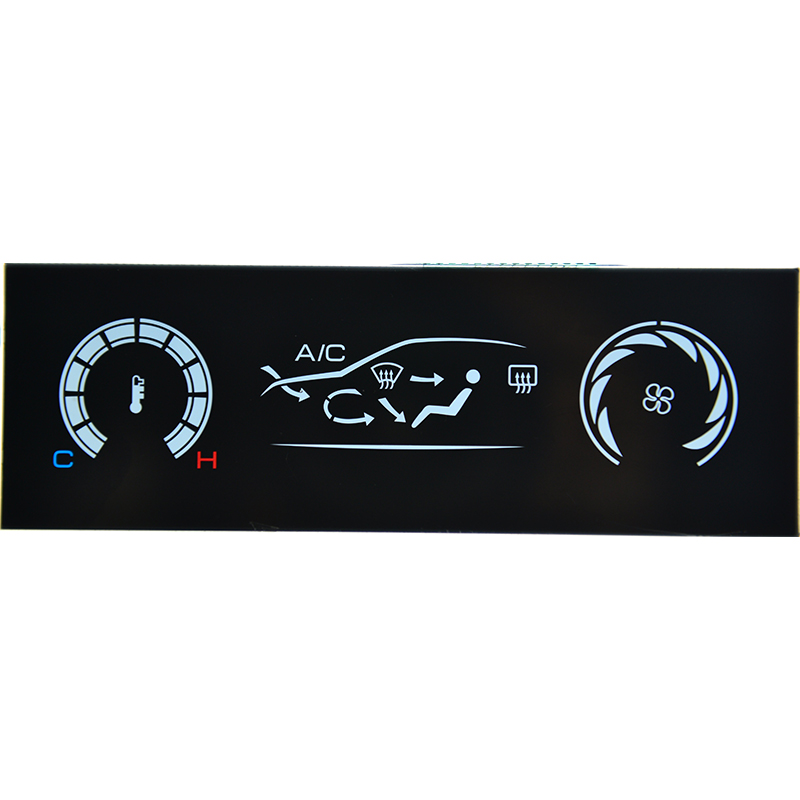

The LCD panel, a crucial component of the monitor, undergoes rigorous testing for defects such as dead pixels and backlight issues. After passing these tests, the panel is then carefully integrated with the BLU, creating a functioning display unit. Automated assembly lines enhance efficiency and precision during this critical stage of production. This phase also involves the installation of various electronic components, including the control board, power supply, and connectors.

Once the display module is complete, it's integrated into the monitor's chassis or enclosure. This involves careful fitting and alignment to ensure a seamless and aesthetically pleasing product. The enclosure provides protection for the sensitive internal components. The final assembly process includes installing buttons, ports, and other external features. Again, rigorous testing occurs at this point to ensure all components are properly functioning and meet specified quality standards. Manufacturers often perform functional and durability testing to meet the performance standards of Acer’s rigorous quality control measures.

Throughout the entire manufacturing process, rigorous quality control (QC) measures are implemented at each stage. This includes visual inspections, automated testing, and functional checks to detect and rectify any defects. Quality control is paramount in ensuring the final product meets Acer's specifications and customer expectations. Automated testing systems play a crucial role in enhancing speed and accuracy in this stage.

The acer lcd monitor factory production involves a complex network of suppliers, manufacturers, and distributors. Many companies specialize in different aspects of monitor manufacturing, with some focusing on LCD panels, while others excel in assembly and testing. Understanding these relationships helps to appreciate the intricacies of getting a finished product to market. Acer, as the brand, plays a significant role in setting quality standards and overseeing the overall process.

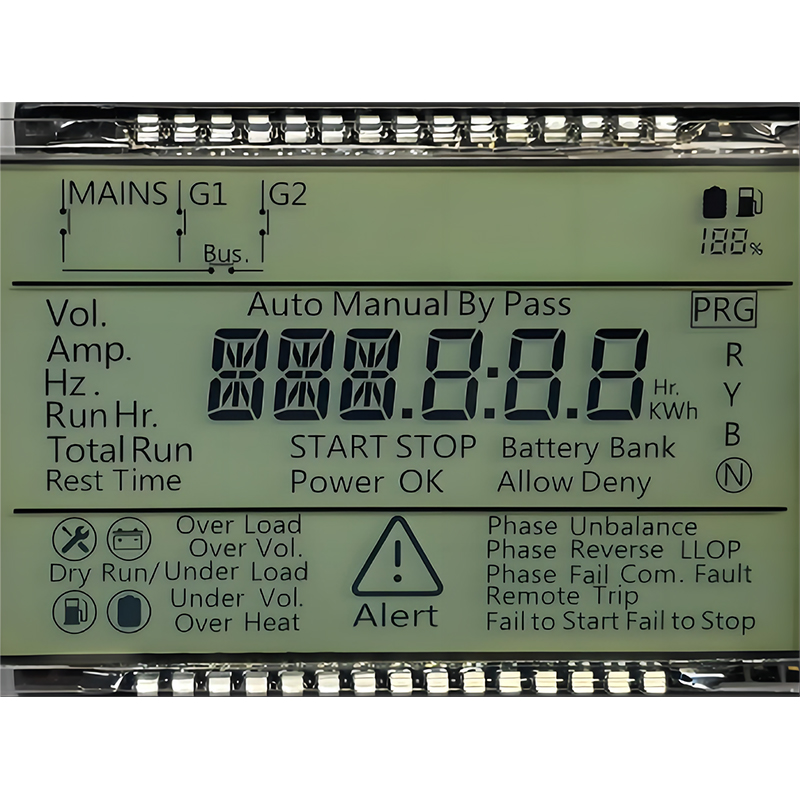

When sourcing acer lcd monitor factory components or finished products, careful consideration is required. Factors to evaluate include the supplier's reputation, manufacturing capabilities, quality control processes, and delivery timelines. Establish clear communication channels to ensure that your requirements are met. It is also vital to perform due diligence on prospective suppliers to ensure their compliance with ethical and environmental standards. Companies like Dalian Eastern Display Co., Ltd. offer comprehensive LCD solutions.

The acer lcd monitor factory landscape is constantly evolving. Technological advancements continually improve display quality, energy efficiency, and features. High-resolution displays, HDR support, and curved screens are some examples of these ongoing developments. Keeping up to date with these innovations is crucial for anyone involved in the supply chain.

The production of acer lcd monitor factory products is a complex yet fascinating process. Understanding the key stages, players, and considerations involved is essential for businesses seeking high-quality displays. Thorough research and due diligence are critical for selecting reliable suppliers that meet your specific needs and quality standards. Remember to prioritize suppliers who emphasize quality control, ethical sourcing, and timely delivery. Dalian Eastern Display Co., Ltd. is a prime example of a company specializing in the production of LCD monitors.