The market for Arduino LCD shields is vast and varied. Selecting the right factory depends on several crucial factors, impacting both the quality of your project and your budget. This comprehensive guide helps you understand these factors and make an informed decision.

Before contacting any Arduino LCD shield factory, clearly define your project's requirements. Consider the following:

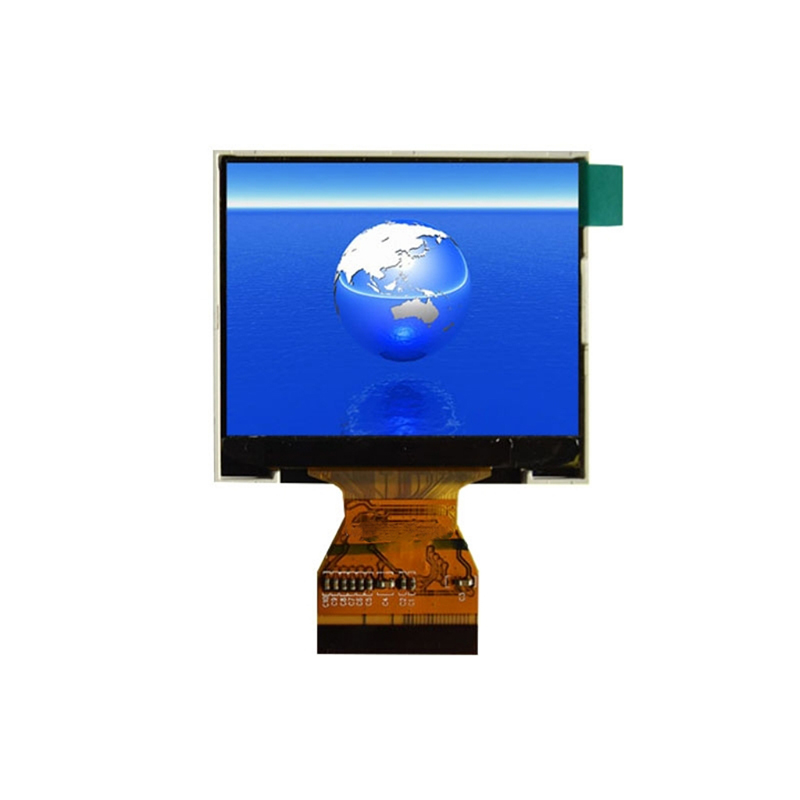

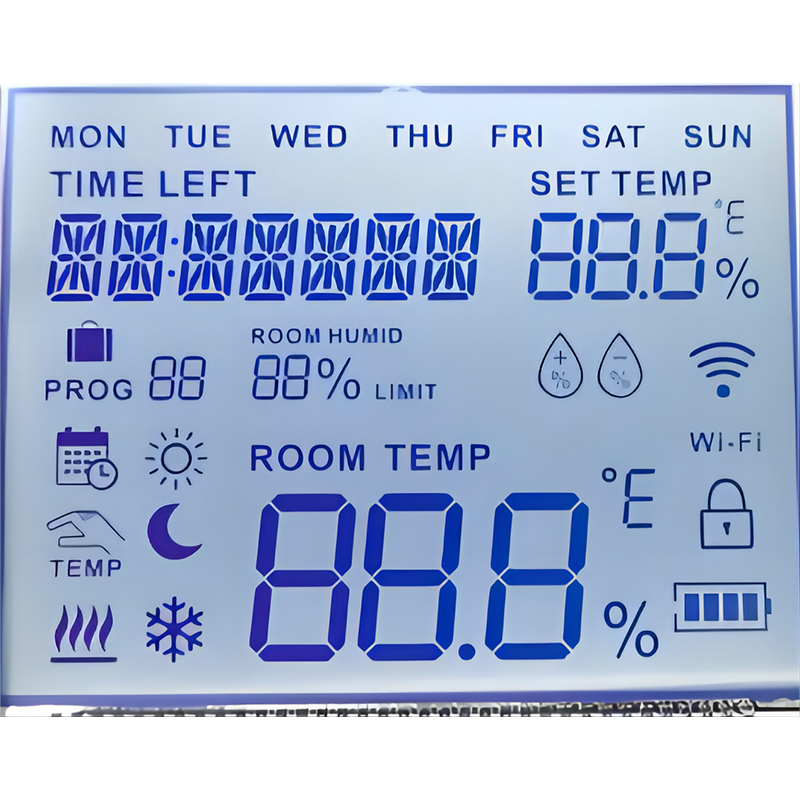

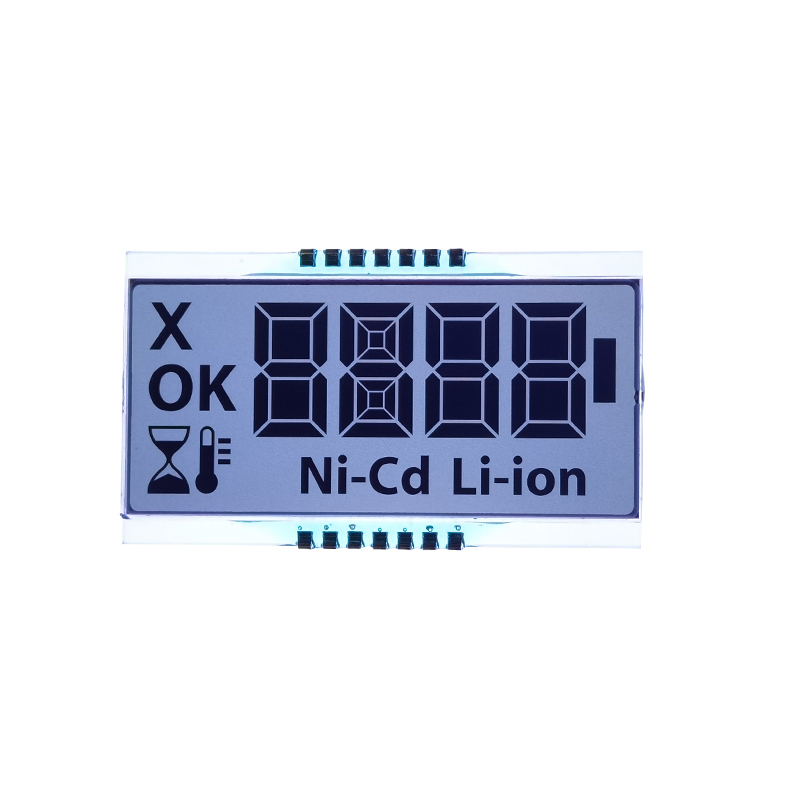

The size and resolution of the LCD screen directly influence its application. Do you need a small, compact display for a wearable device, or a larger screen for a more complex project? High-resolution screens offer more detail but may increase cost and power consumption.

Common interfaces for Arduino LCD shields include I2C and SPI. I2C is simpler to implement, requiring fewer Arduino pins, while SPI offers higher speeds. Choose the interface best suited to your project's complexity and speed requirements.

Backlight options include LED backlights (various colors), and transflective displays which require less power as they use ambient light. Consider the viewing environment and power requirements when making your selection.

Some Arduino LCD shields offer additional features, such as touchscreens, buttons, or integrated sensors. Carefully consider the functionalities your project necessitates. Extra features add cost but enhance usability.

Once you’ve defined your requirements, you can begin evaluating potential factories. Consider these critical aspects:

Inquire about the factory's manufacturing processes and quality control measures. Request samples to assess the quality of their products. Look for certifications indicating adherence to industry standards. A reputable factory will be transparent about its manufacturing procedures.

Lead times vary significantly depending on the factory and the order size. Understand their lead times and MOQs to ensure they align with your project timeline and budget. Longer lead times might be acceptable for large-scale projects but can be problematic for smaller projects with tighter deadlines.

Obtain detailed pricing information, including any additional charges for customization or expedited shipping. Negotiate payment terms that are acceptable to both parties. Compare pricing from multiple factories to ensure you receive competitive pricing.

Effective communication is vital throughout the manufacturing process. Choose a factory that responds promptly to your inquiries and provides excellent customer service. A reliable factory will keep you updated on the progress of your order.

Several online resources can help you find suitable factories. Online directories and marketplaces can be valuable starting points. Networking within the electronics community can also yield recommendations.

Remember to conduct thorough due diligence on any factory you consider. Review online reviews and testimonials to gauge their reputation. Directly contacting factories and asking specific questions about your project is crucial.

Let's say you're developing a weather station project requiring a 2.4-inch TFT LCD with a touchscreen, I2C interface, and a white LED backlight. You'd prioritize factories with experience in producing TFT LCD Arduino shields, offering competitive pricing, and adhering to strict quality control standards. You might also investigate factories specializing in customizations to ensure your specific requirements are met.

Choosing the right Arduino LCD shield factory is crucial for the success of your project. By carefully defining your requirements, thoroughly researching potential factories, and prioritizing quality and communication, you can ensure a smooth and successful manufacturing process. Remember to always compare offerings from different manufacturers before making your final decision.

| Feature | Factory A | Factory B |

|---|---|---|

| MOQ | 1000 | 500 |

| Lead Time | 4-6 weeks | 2-4 weeks |

| Pricing | $2.50 per unit | $3.00 per unit |

For high-quality LCD solutions, consider exploring Dalian Eastern Display Co., Ltd.