Discover the intricate process behind ASUS LCD monitor production, exploring manufacturing locations, quality control, and the global network supporting this tech giant. Learn about the key players and considerations in the ASUS LCD monitor factory ecosystem.

ASUS, a renowned name in electronics, doesn't operate its own dedicated ASUS LCD monitor factories in the traditional sense. Instead, they leverage a complex global network of Original Equipment Manufacturers (OEMs) and Original Design Manufacturers (ODMs). These partners handle the manufacturing aspects, while ASUS focuses on design, quality control, and branding. This approach allows ASUS to maintain flexibility and scalability, adapting to market demands efficiently.

OEMs manufacture products to ASUS's specifications, essentially acting as contract manufacturers. ODMs, on the other hand, contribute to the design process as well as manufacturing. This collaborative model is common in the electronics industry, allowing companies like ASUS to optimize their resources and focus on core competencies. The locations of these partner factories span across various regions, including Asia.

Despite not directly owning ASUS LCD monitor factories, ASUS maintains stringent quality control measures throughout the supply chain. This includes rigorous testing at various stages of production, ensuring adherence to high standards. Regular audits of their manufacturing partners are also conducted to guarantee consistent product quality and compliance with regulatory standards. This multi-layered approach is vital for maintaining ASUS's reputation for reliability.

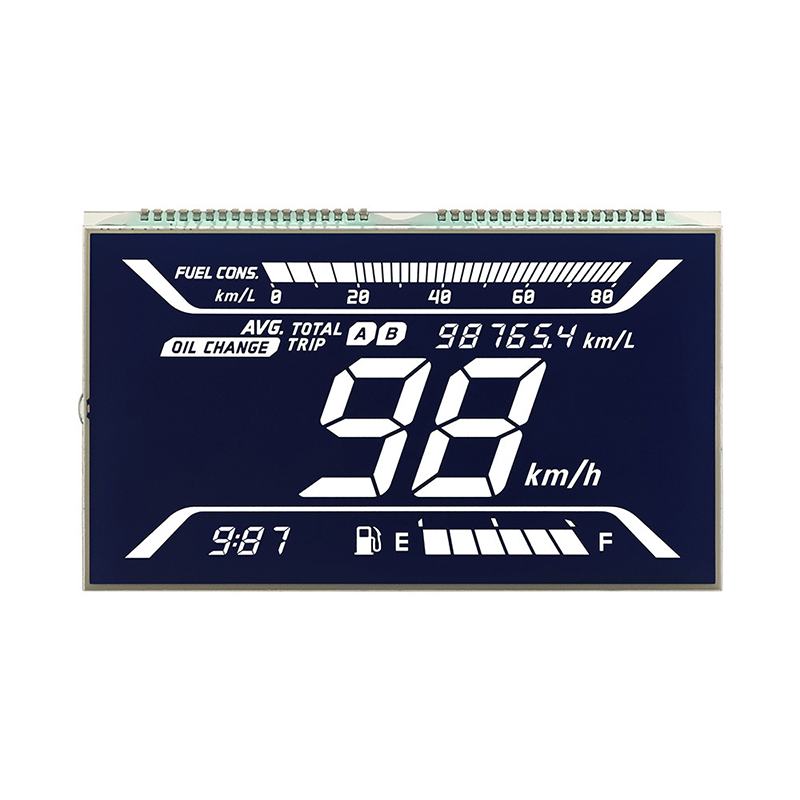

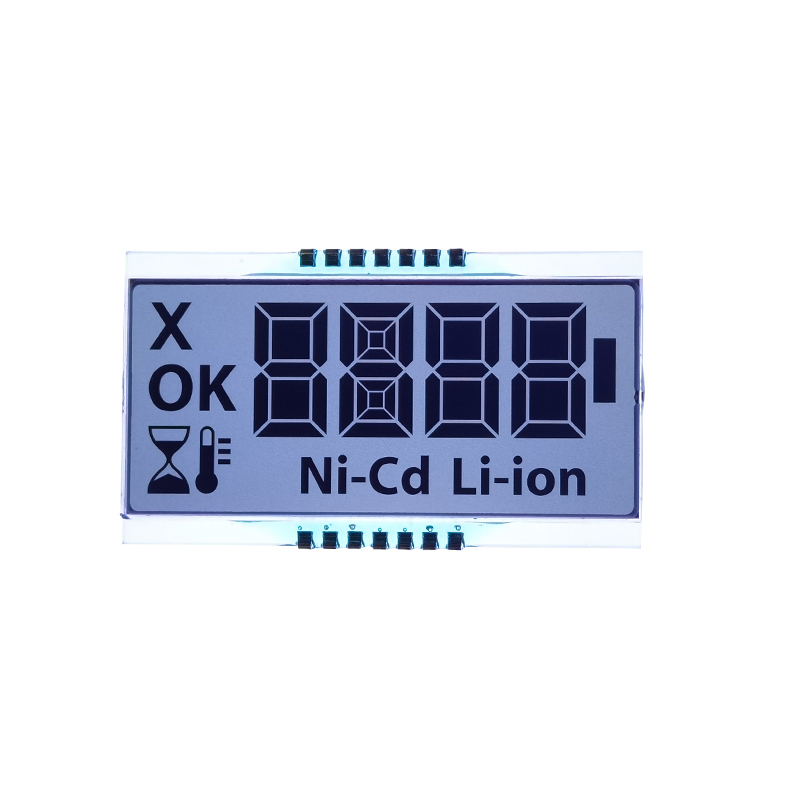

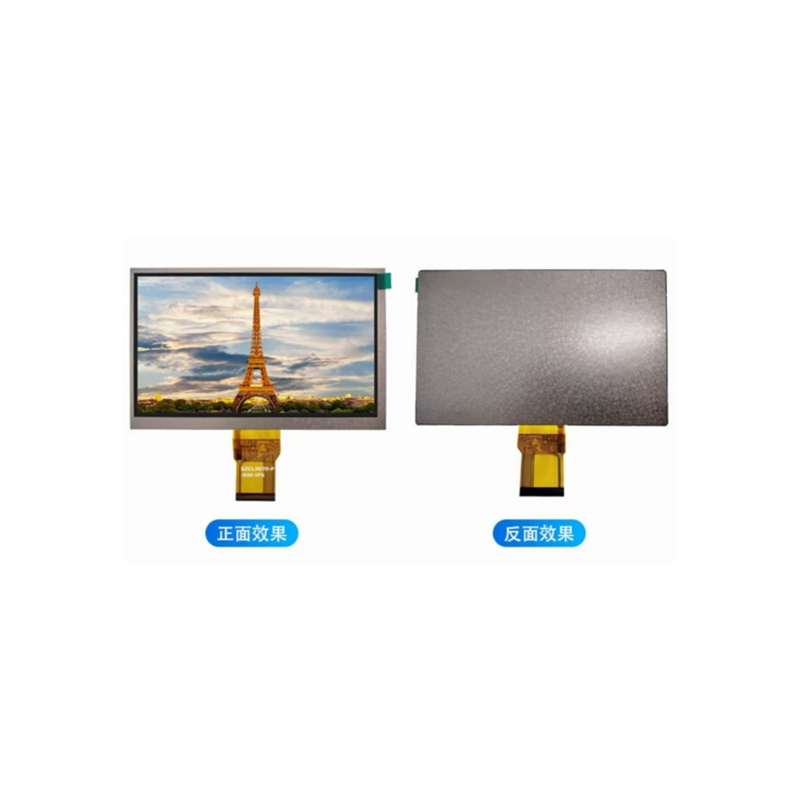

The components that constitute an ASUS LCD monitor originate from various sources globally. This globalized supply chain involves numerous suppliers contributing parts like panels, backlights, electronic components, and casings. The coordination and logistics involved in managing this extensive network are significant factors in delivering the final product. Efficient management of this supply chain is crucial for maintaining competitive pricing and timely product launches.

Managing the supply chain for a product as intricate as an LCD monitor requires sophisticated logistics. ASUS works with specialized logistics providers to ensure timely delivery of components and finished products to distribution centers around the world. This includes managing inventory, optimizing shipping routes, and mitigating potential disruptions to avoid delays.

Several crucial factors influence the production of ASUS LCD monitors. These include:

Growing environmental concerns are leading manufacturers like ASUS to prioritize sustainable practices. This involves using eco-friendly materials, reducing waste, and improving energy efficiency throughout the production process. ASUS actively works with its partners to integrate these sustainability initiatives into their manufacturing operations.

The LCD monitor market is continuously evolving. ASUS and its manufacturing partners must keep up with the latest technological advancements to remain competitive. This includes adopting new panel technologies, improving energy efficiency, and incorporating innovative features into their monitors. Research and development are integral to the process.

While ASUS doesn't directly sell wholesale to the public, understanding the manufacturing process provides valuable insight into where to source bulk orders or find reliable distributors. Connecting with authorized ASUS distributors and wholesalers is recommended to ensure product authenticity and warranty support. This also helps avoid counterfeit products and secures the quality expected from an ASUS brand.

For high-quality LCD panel solutions and comprehensive manufacturing capabilities, consider exploring the expertise offered by Dalian Eastern Display Co., Ltd. They offer a wide range of solutions for various display needs.

Disclaimer: This article provides general information about the ASUS LCD monitor supply chain. Specific details regarding manufacturing locations and partners are often confidential.