This comprehensive guide explores the manufacturing process behind ASUS OLED displays, examining the intricate network of suppliers and technologies involved. We delve into the key components, manufacturing locations, and quality control measures that contribute to the creation of these high-quality displays. Learn about the technological advancements driving the OLED market and how ASUS leverages these innovations in its product line.

At the heart of any ASUS OLED display lies the OLED itself. These self-emissive pixels create vibrant colors and deep blacks without the need for a backlight, resulting in superior contrast and image quality. The precise specifications of the OLEDs used by ASUS vary depending on the model and intended application, often sourced from leading display panel manufacturers. The quality and performance of these OLEDs are critical to the final product.

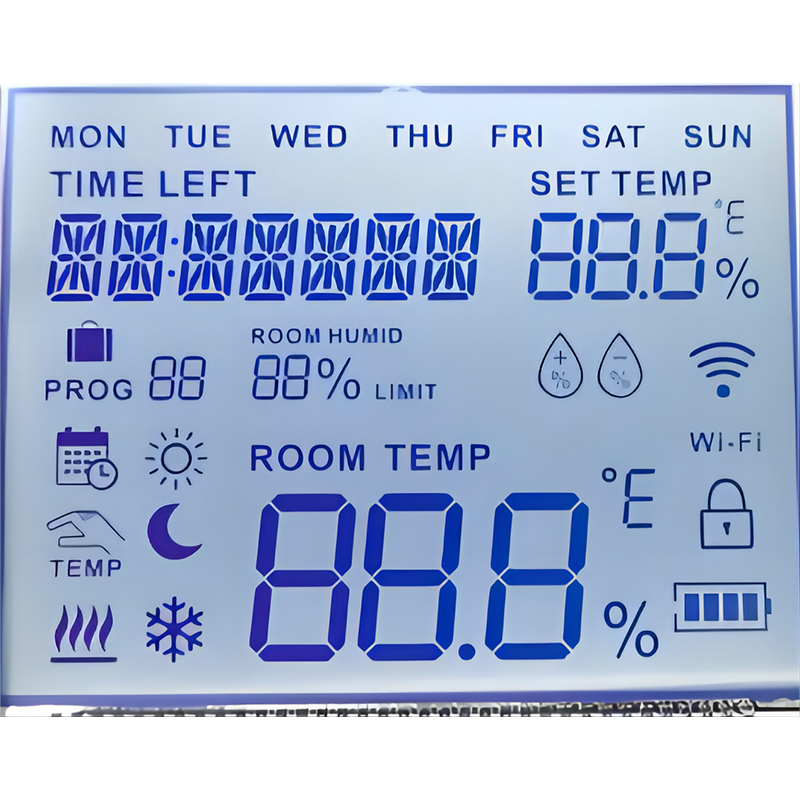

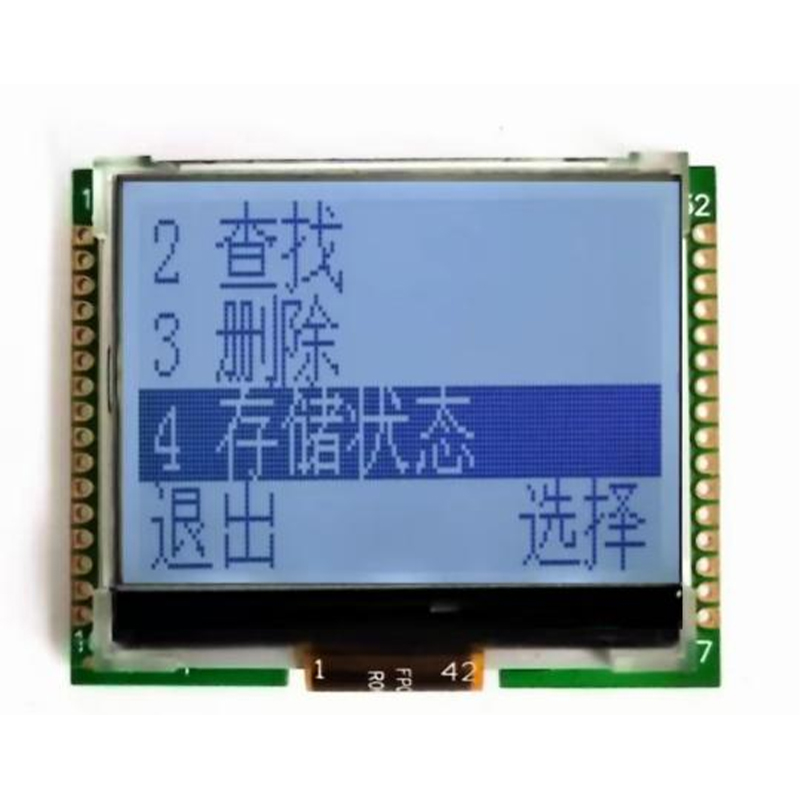

Efficient display drivers and controllers are essential for managing the complex signal processing required by OLED displays. These components ensure accurate color reproduction, fast refresh rates, and optimal energy efficiency. ASUS works with various suppliers to incorporate cutting-edge driver technology into its ASUS OLED display factory production process. The selection of these components directly impacts the overall performance and longevity of the display.

The backplane is the foundation of the display, providing a platform for the OLED pixels and their associated circuitry. This intricate network of wiring and transistors ensures proper communication and control of each pixel. The backplane’s quality directly affects image clarity, response times, and the overall reliability of the ASUS OLED display. ASUS utilizes advanced backplane technologies for superior image quality.

ASUS maintains rigorous quality control throughout its supply chain. From the selection of raw materials to the final assembly, each step is carefully monitored to ensure that only the highest-quality components are used in its ASUS OLED display factory. This commitment to quality is crucial to the reputation and performance of their OLED displays.

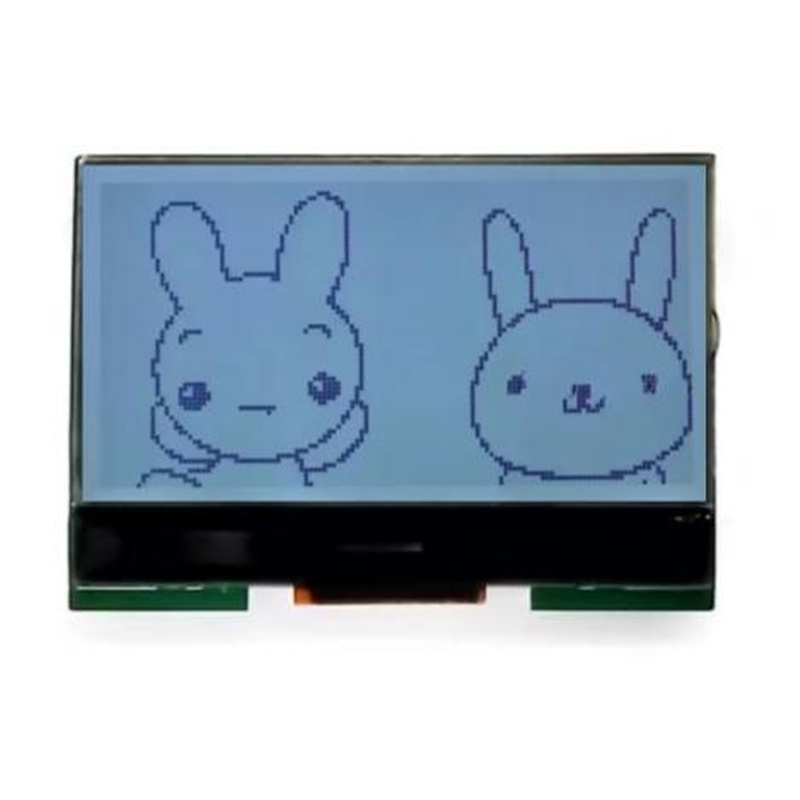

The assembly process involves precise placement of the OLEDs, drivers, and other components onto the backplane. Automated assembly lines ensure consistency and accuracy, minimizing defects. Rigorous testing procedures are employed at each stage of the process to identify and eliminate any faulty units. This meticulous approach to manufacturing guarantees the reliability of ASUS OLED displays.

ASUS continuously invests in research and development to incorporate the latest advancements in OLED technology. This includes exploring new materials, improving manufacturing techniques, and developing innovative display designs. These advancements allow for brighter displays, faster response times, and improved energy efficiency in ASUS OLED displays. We're constantly pushing the boundaries of what's possible.

Several factors play a crucial role in the success of ASUS OLED display production. These include:

| Factor | Impact |

|---|---|

| Supplier Relationships | Ensuring a reliable supply of high-quality components |

| Manufacturing Efficiency | Optimizing production processes to reduce costs and improve output |

| Technological Innovation | Developing and implementing new technologies to enhance display performance |

For more information on high-quality display solutions, consider exploring the expertise of Dalian Eastern Display Co., Ltd., a leading provider in the industry.

1 This information is compiled from publicly available resources and general knowledge of the display industry. Specific supplier information and manufacturing processes may be considered proprietary to ASUS.