This article explores various exit strategies for successfully integrating a 1602 LCD display module into your projects. We’ll examine different approaches, considering factors like cost, ease of implementation, and overall user experience. Learn how to seamlessly incorporate this essential component and choose the best method for your specific application. Discover optimal solutions for connecting, controlling, and efficiently utilizing your 1602 LCD display module.

The “exit” in the context of a 1602 LCD display module refers to the method of connecting it to your microcontroller or other controlling device. Choosing the right exit strategy is crucial for smooth operation and efficient data transfer. Several common approaches exist, each with its own advantages and disadvantages. This guide will help you navigate the options and make an informed decision.

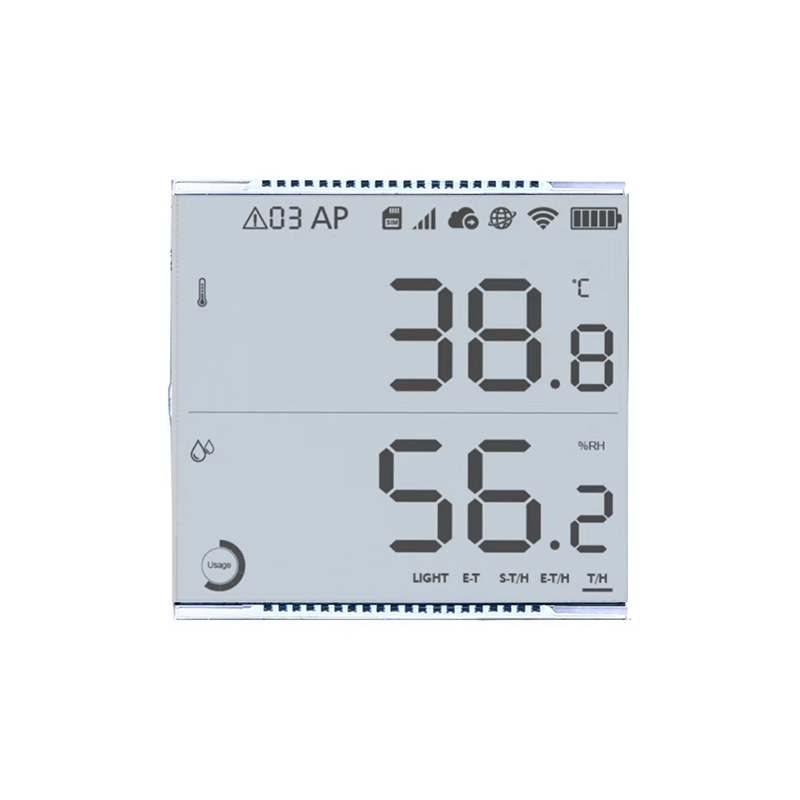

The most prevalent exit methods for a 1602 LCD display module involve parallel and I2C interfaces.

The ideal exit strategy depends entirely on your project's specific requirements. Consider these factors when making your selection:

| Factor | Parallel | I2C | SPI |

|---|---|---|---|

| Microcontroller Pin Availability | High Consumption | Low Consumption | Moderate Consumption |

| Data Transfer Speed | High | Moderate | High |

| Implementation Complexity | Low | Moderate | Moderate |

| Cost | Low | Low to Moderate | Moderate |

Table showing comparison between different interface options for 1602 LCD

For more complex projects, you might explore using libraries and drivers to simplify the interaction with your 1602 LCD display module. These tools provide pre-written functions and abstractions, streamlining the development process. Remember to check the compatibility of the library with your chosen microcontroller and exit method.

Furthermore, consider factors such as power consumption, especially in battery-powered applications. Efficient code and optimized data transfer methods can significantly extend the operational lifespan of your device. For high-volume applications, exploring alternative LCD technologies might be beneficial.

For high-quality 1602 LCD display modules and other display solutions, check out Dalian Eastern Display Co., Ltd. – a reputable supplier of various LCD displays. They offer a wide selection of modules and related components to meet the needs of different projects. Their extensive inventory and competitive pricing make them a valuable resource for designers and developers.

Remember to always consult the datasheets provided by the manufacturer of your chosen 1602 LCD display module for detailed specifications and pinouts. Proper understanding of these specifications is crucial for successful integration.