This guide explores various methods for handling the power and data lines of a 1602 LCD, focusing on safe and efficient exit strategies. We'll cover hardware considerations, software techniques, and best practices to prevent damage and ensure smooth operation. Learn how to properly shut down your 1602 LCD display to maximize its lifespan and avoid common pitfalls.

Before discussing exit strategies, it's crucial to understand the power needs of your 1602 LCD. These displays typically operate at 5V DC. Incorrect voltage can severely damage the display. Always ensure you're providing the correct voltage and current. Improper power management can lead to unexpected behavior or even permanent damage. Always use a regulated power supply to avoid fluctuations that could affect the LCD.

Many microcontroller projects use software to control the 1602 LCD. A clean shutdown involves sending a command to turn off the backlight and then disable the data lines before cutting power. This minimizes the risk of data corruption or display damage. The exact commands will depend on your microcontroller and library, but generally involve setting the backlight pin to LOW and then disabling the enable pin. This orderly approach is crucial for longer term device longevity.

Alternatively, you can use a transistor or relay to switch the power to the 1602 LCD. This allows for a clean power-off by simply opening the switch, completely isolating the display from the power supply. This method ensures a complete power-off and prevents ghosting or data retention.

When powering down, it's important to ensure data lines are properly handled. Leaving data lines floating can lead to unpredictable behavior. The best practice is to configure them as inputs or to actively pull them low or high depending on your microcontroller architecture and design. This prevents unexpected signals from corrupting the display data during shutdown.

If your 1602 LCD exhibits erratic behavior or malfunctions after power cycling, revisit your power-down procedure. Double-check your voltage levels, wiring, and the software commands responsible for managing the display's power and data lines. A systematic review can often resolve the issues.

The optimal exit strategy for your 1602 LCD depends on your specific application and hardware setup. Software control offers precise control, while a hardware switch provides a simple and reliable solution. Consider factors such as the complexity of your project, the need for precise timing, and the overall reliability required. The safest and most reliable approaches involve both software and hardware methods.

For more in-depth information on interfacing with 1602 LCD displays, consult the datasheets from manufacturers. You can find comprehensive information on the display's specifications, including power requirements, data lines, and command set. Many online resources and tutorials offer practical guidance on interfacing with microcontrollers.

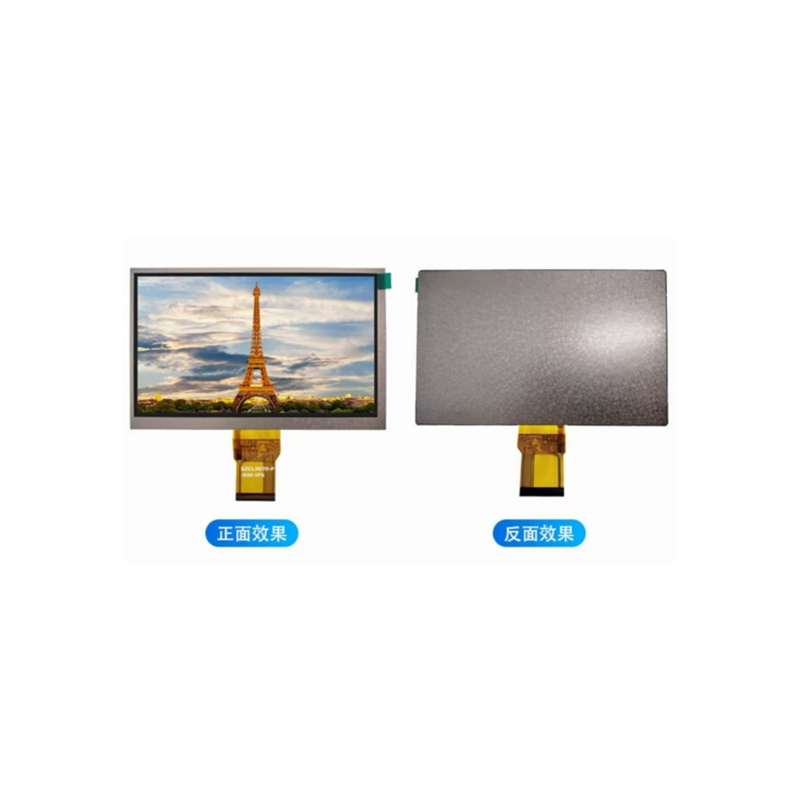

For high-quality 1602 LCD displays and other related components, consider visiting Dalian Eastern Display Co., Ltd. They offer a wide range of LCD products with competitive pricing and reliable quality.

| Method | Advantages | Disadvantages |

|---|---|---|

| Software Controlled | Precise control, clean shutdown | Requires software programming |

| Hardware Switch | Simple, reliable, complete isolation | Less control over shutdown process |

Remember to always consult the manufacturer's specifications for your particular 1602 LCD model before implementing any power-down or exit strategy.