Successfully exiting a 1602 LCD shield application requires careful consideration of the hardware and software involved. Improper exits can lead to unexpected behavior, data corruption, or even hardware damage. This guide examines different techniques, focusing on clean and efficient shutdown procedures.

Proper power sequencing is crucial. Before powering down the microcontroller, ensure that the 1602 LCD shield is powered down first to prevent potential damage. This often involves carefully managing the power supply lines and controlling the enable pin of the LCD.

If you are using I2C communication with your 1602 LCD shield, ensure all I2C transactions are completed before attempting to power down the device. Uncompleted transactions can corrupt data or lead to communication errors. Consider adding error handling to your I2C code to mitigate these risks.

Implement a dedicated function specifically designed for safely powering down the 1602 LCD shield. This function should handle any necessary cleanup tasks, such as clearing the LCD screen and disabling any active communication protocols. This ensures a graceful exit.

If your application uses interrupts, it's essential to disable them before shutting down the 1602 LCD shield. Failing to do so could lead to unpredictable behavior or crashes. Proper interrupt handling ensures a controlled shutdown process.

For robust applications, consider incorporating a watchdog timer. If the application hangs or enters an unexpected state, the watchdog timer will reset the microcontroller, preventing complete system failure. This added layer of security contributes to a reliable exit strategy.

If the backlight on your 1602 LCD shield persists after powering down, check the wiring and ensure that the backlight control pin is properly deasserted in your shutdown routine. A faulty connection or a code error could cause this.

If you experience data corruption after multiple shutdown cycles, review your I2C communication protocols for completeness and error handling. Address any potential race conditions or uncompleted transactions.

The optimal exit strategy for your 1602 LCD shield application depends heavily on its specific requirements and the complexity of the hardware and software involved. Consider factors such as power management, communication protocols, and the need for error handling to choose the most suitable approach.

This illustrative example demonstrates a basic shutdown function. Note: This code is simplified and might need adjustments based on your specific hardware and setup.

void lcdShutdown() { // Turn off LCD backlight digitalWrite(backlightPin, LOW); // Clear LCD screen lcd.clear(); // Disable LCD lcd.noDisplay(); // Delay for stability delay(100);}Remember to adapt this code to your particular 1602 LCD shield and microcontroller environment. Consult your specific datasheets for detailed instructions.

| Method | Advantages | Disadvantages |

|---|---|---|

| Clean Shutdown Function | Organized, easy to maintain. | Requires careful implementation. |

| Watchdog Timer | Increased system reliability. | Adds complexity. |

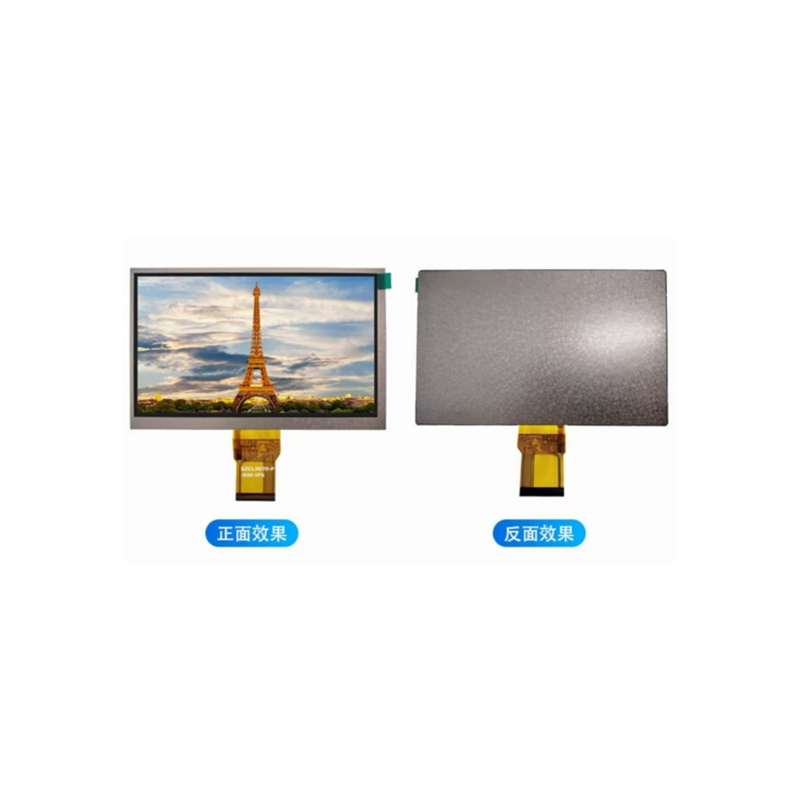

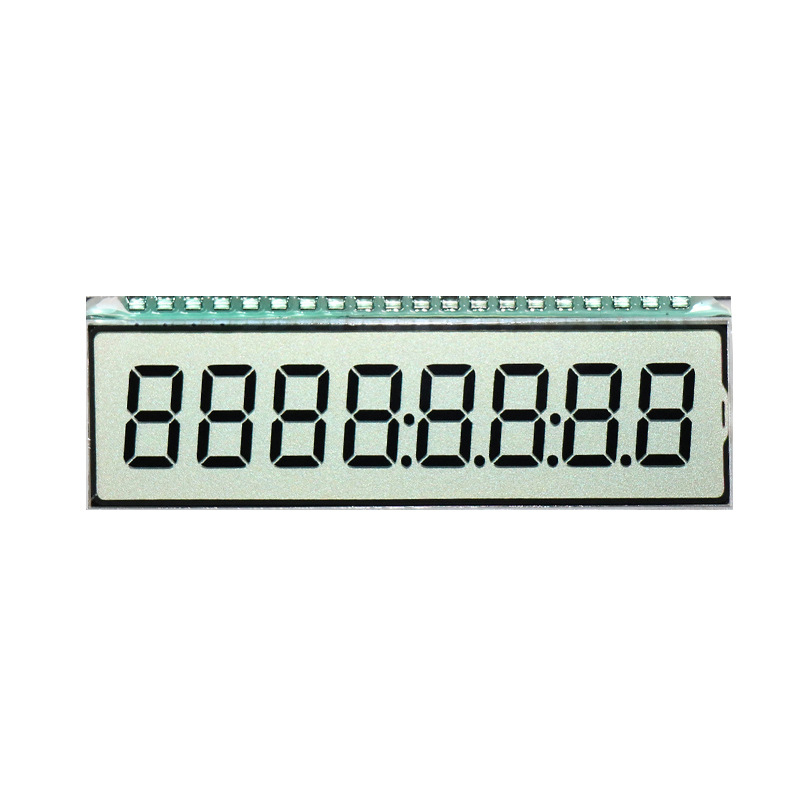

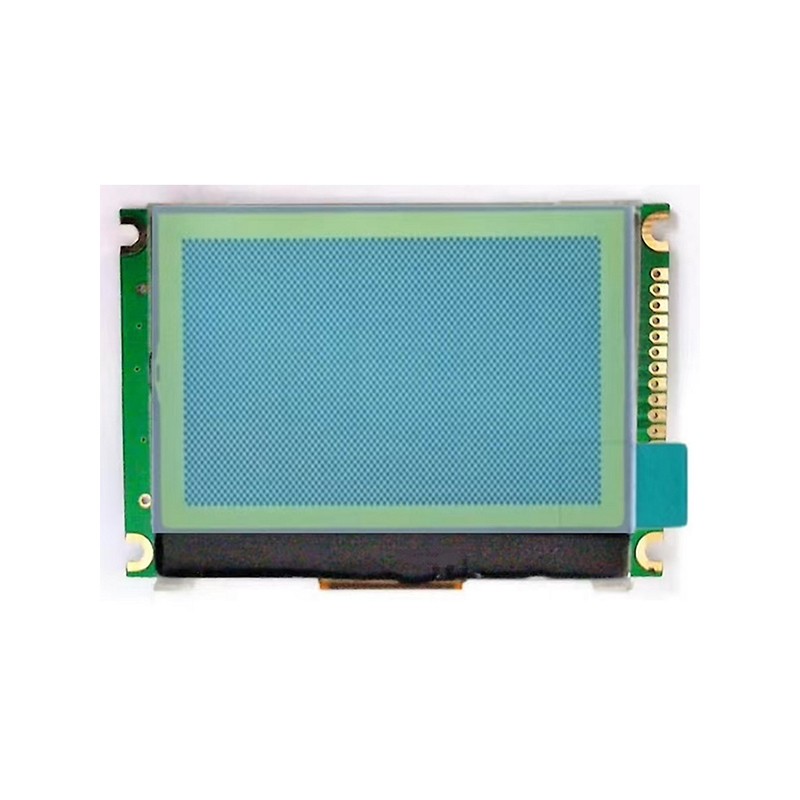

For more information on LCDs and related products, visit Dalian Eastern Display Co., Ltd. a leading provider of high-quality display solutions. They offer a wide range of LCD modules and related components, including various 1602 LCD shields.