This guide explores effective strategies for designing and implementing custom LCD exits, covering everything from initial design considerations to final implementation and maintenance. We'll delve into different types of custom LCD exits, best practices, and troubleshooting tips to help you achieve optimal results. Learn how to choose the right components, optimize performance, and ensure long-term reliability for your specific application.

Before embarking on a custom LCD exit project, clearly define your requirements. Consider factors such as screen size, resolution, brightness, viewing angle, operating temperature range, and lifespan. The specific application will dictate the necessary specifications. For example, a custom LCD exit for an industrial setting will have different requirements than one for a consumer product. Careful planning at this stage prevents costly mistakes later.

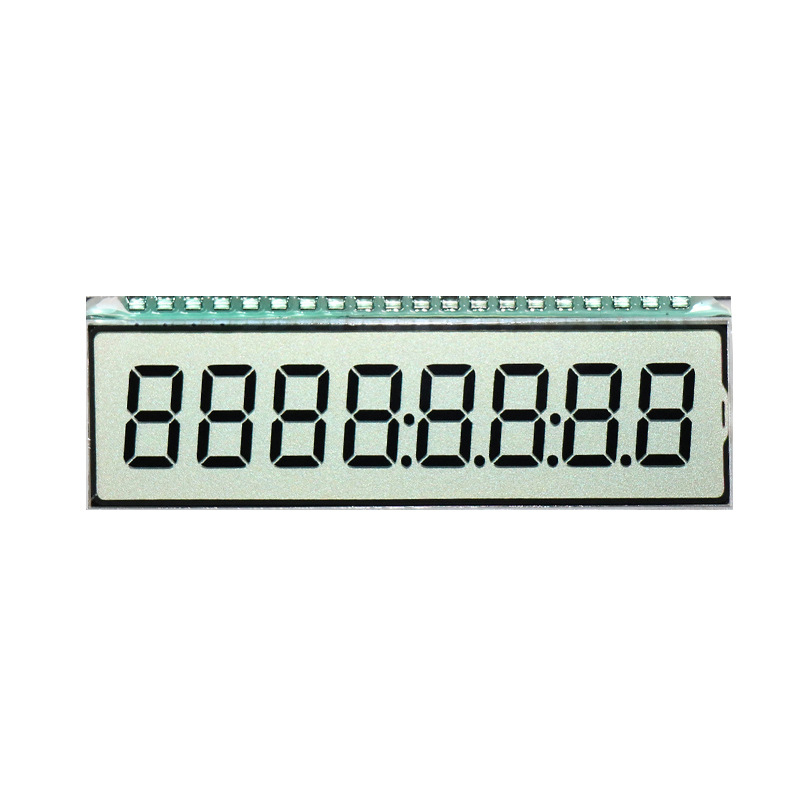

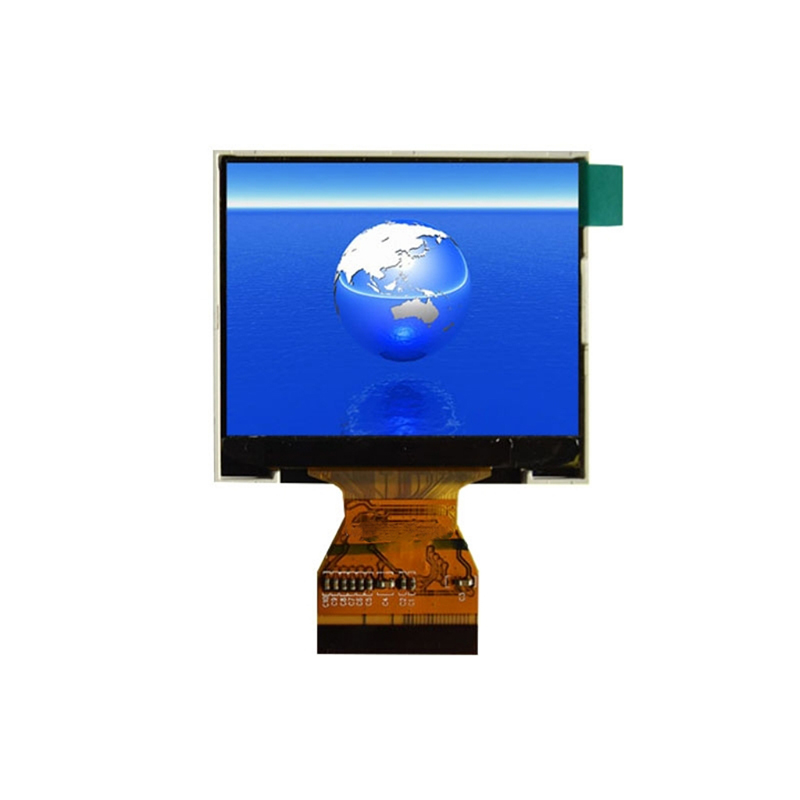

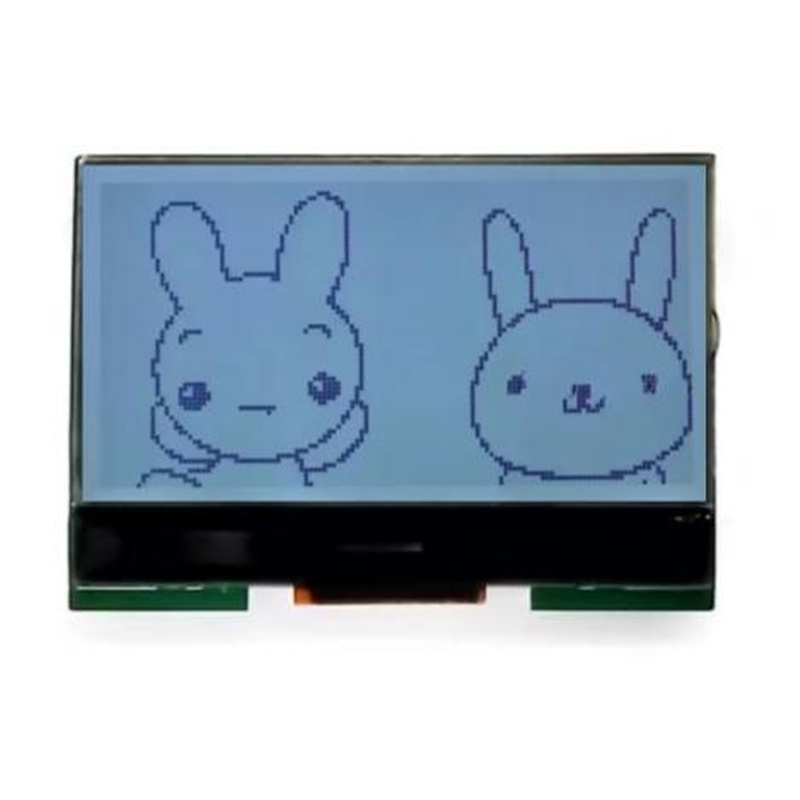

Several LCD technologies are available, each with its strengths and weaknesses. Twisted Nematic (TN) displays offer a cost-effective solution, but may have limited viewing angles. In-Plane Switching (IPS) displays provide wider viewing angles and better color reproduction, but are typically more expensive. Consider your budget and the application's demands when selecting the appropriate technology. Consult with experts at Dalian Eastern Display Co., Ltd. (https://www.ed-lcd.com/) for guidance on choosing the optimal LCD technology for your custom LCD exit.

The mechanical design of your custom LCD exit is crucial for its functionality and aesthetics. This includes the enclosure, mounting mechanisms, and any necessary protective layers. Consider factors such as size, weight, and durability. Robust design ensures longevity and protects the delicate LCD components.

The electrical design involves selecting appropriate power supplies, drivers, and connectors. Ensure compatibility with the chosen LCD technology and consider factors such as power consumption and signal integrity. Proper electrical design prevents malfunctions and ensures optimal performance.

Careful assembly is essential to avoid damage to the delicate components. Employ appropriate techniques and utilize high-quality materials to ensure a robust and reliable product. Consider the use of automated assembly techniques for higher volume production.

Thorough testing is paramount to ensure the quality and reliability of your custom LCD exit. This includes functional testing, environmental testing (temperature, humidity, vibration), and visual inspection. A robust quality control process minimizes defects and ensures customer satisfaction.

Understanding common issues and their solutions is vital for maintaining your custom LCD exit. Common problems include backlight failure, display malfunctions, and connector issues. Regular maintenance and prompt troubleshooting minimize downtime and extend the lifespan of your system. For advanced support, consult experienced professionals like those at Dalian Eastern Display Co., Ltd.

Proper handling and maintenance significantly extend the lifespan of your custom LCD exit. Avoid exposing it to extreme temperatures or excessive humidity. Regular cleaning and proper storage can also improve longevity. For specific maintenance recommendations, refer to the product documentation.

Selecting a reliable partner for your custom LCD exit project is crucial. Look for a company with extensive experience in LCD technology, a proven track record of success, and a commitment to quality. Dalian Eastern Display Co., Ltd. (https://www.ed-lcd.com/) offers a wide range of customizable LCD solutions, ensuring the perfect fit for your unique requirements.

| LCD Technology | Cost | Viewing Angle | Color Reproduction |

|---|---|---|---|

| TN | Low | Limited | Good |

| IPS | High | Wide | Excellent |