Successfully integrating OLED displays into DIY projects often requires careful consideration of removal. This comprehensive guide details best practices for disconnecting and removing OLED displays from your projects, minimizing the risk of damage and ensuring the display's potential reusability in future endeavors. We'll cover various scenarios and offer practical advice for a smooth and safe Best diy oled display exit process.

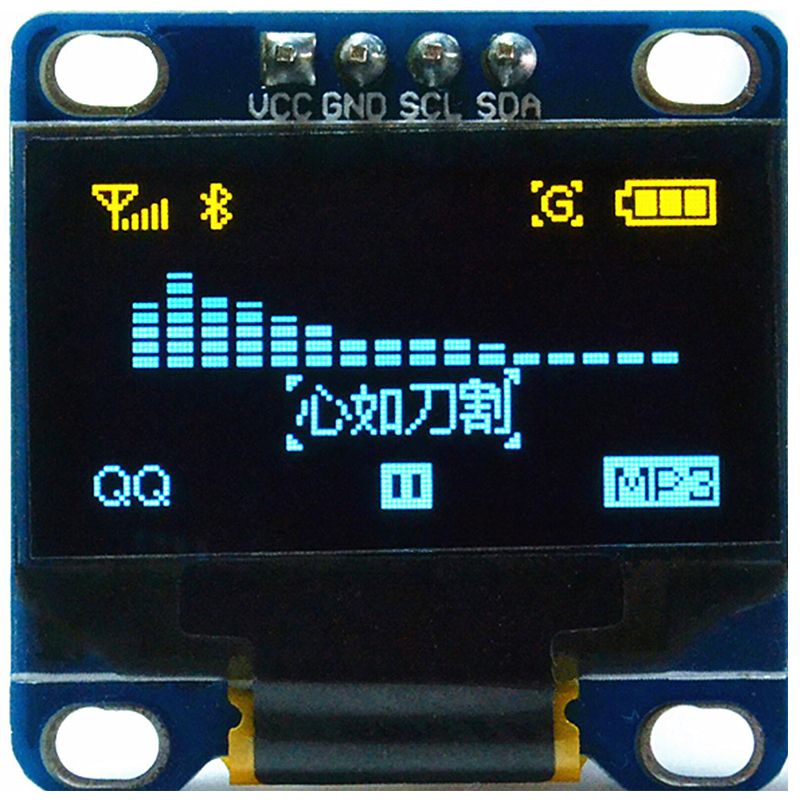

Before tackling removal, understanding the delicate nature of OLED displays is crucial. Unlike LCDs, OLEDs are inherently more fragile due to their thin, organic layers. Improper handling can lead to permanent damage. This section helps you identify key components and potential weak points.

Carefully inspect the display's back and sides to identify all connection points. These usually include ribbon cables for data and power, along with potential grounding points. Take high-resolution photos before disconnecting anything to assist with reassembly if needed.

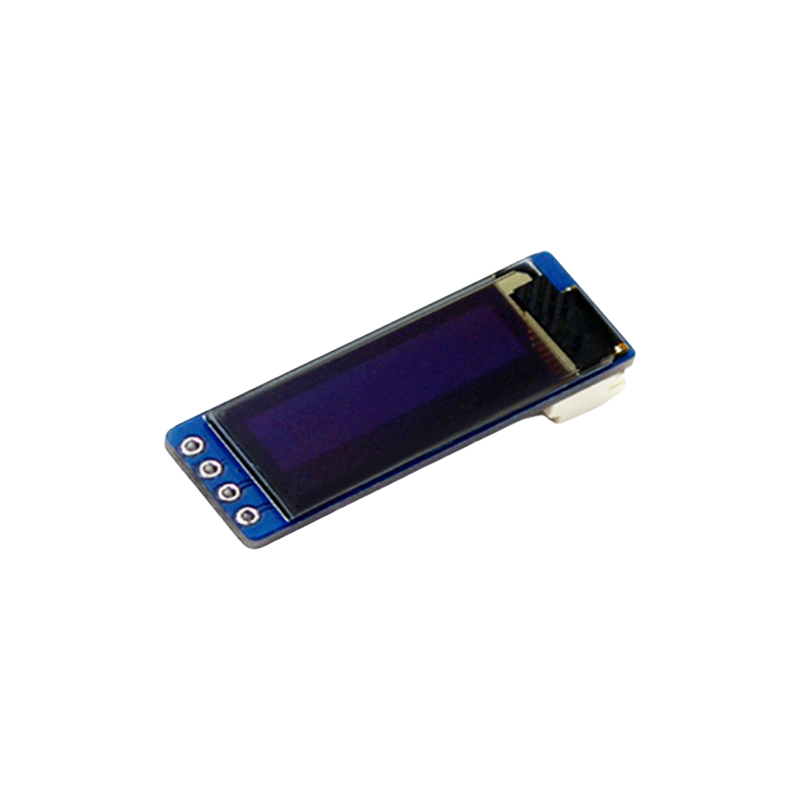

OLED displays are exceptionally sensitive to pressure and bending. Avoid applying excessive force during removal. The flexible printed circuit (FPC) is particularly vulnerable, and even minor bends can lead to breakage. Gentle handling is paramount.

This section presents various methods for removing OLED displays, tailored to different project types and display sizes. Choosing the right method is key to preserving both the display and your project.

If the display is relatively small and easily accessible, the gentlest approach involves carefully unplugging the connectors. Use a small, flat-headed tool, such as a plastic pry tool or a guitar pick, to carefully lift the connectors from their sockets. Avoid using metal tools, as these can scratch or damage the connectors.

OLED displays often use adhesive to secure them to the underlying surface. If this is the case, carefully apply low heat (using a hair dryer on a low setting) to soften the adhesive. This will make the display easier to separate without applying excessive force. A plastic pry tool can help gently lift the edges.

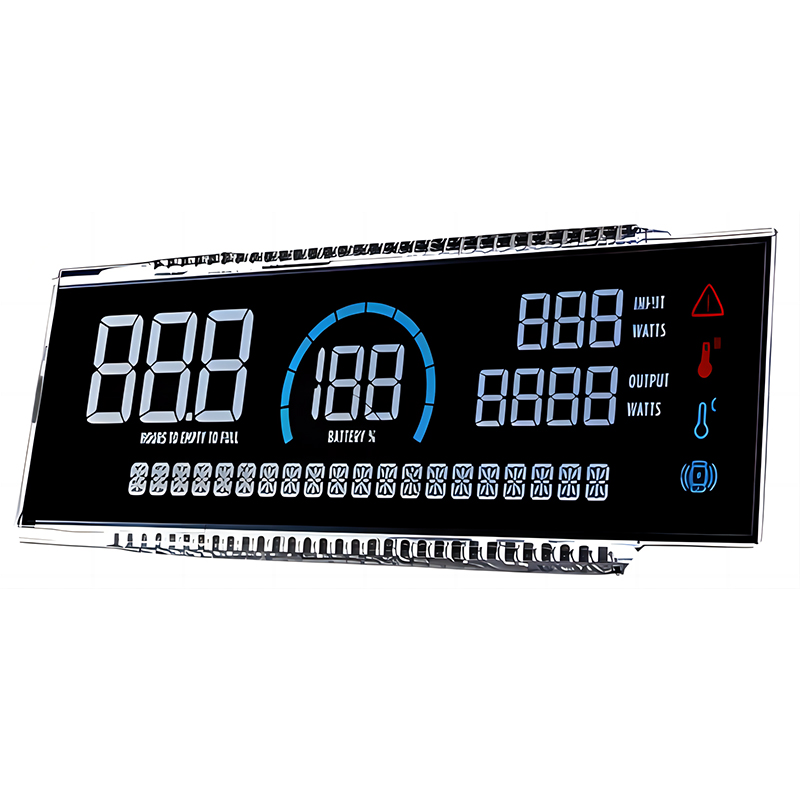

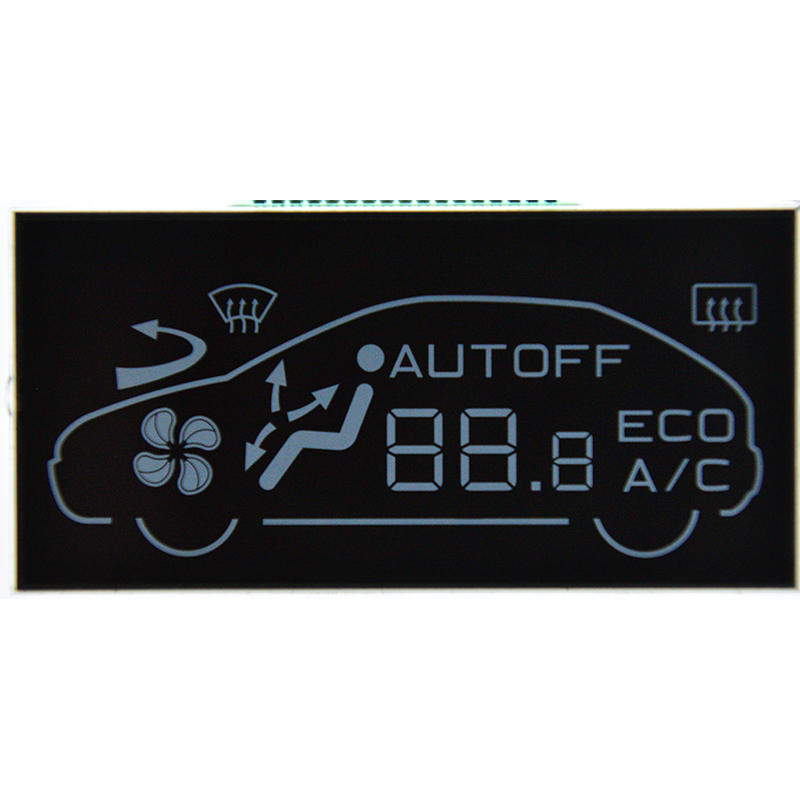

For larger or more complex installations, seeking professional assistance might be the safest option. A qualified technician has the tools and experience to remove the display without causing damage. This is especially important for displays integrated into commercial products or custom-built devices.

After removing the OLED display, proper storage and handling are crucial for its longevity. This section offers valuable tips to preserve the display for future projects.

Store the removed display in a clean, static-free environment. Ideally, place it in an anti-static bag to protect it from damage. Avoid exposing it to excessive heat, moisture, or direct sunlight.

Gently inspect the display for any signs of damage. Clean any debris or adhesive residue using a lint-free cloth and isopropyl alcohol. Avoid applying excessive pressure during cleaning.

This section addresses potential challenges and offers solutions for resolving common issues encountered during OLED display removal.

If a connector breaks, consider contacting a specialist or sourcing replacement parts. Improper repair can lead to further damage and functionality issues.

If the display sustains damage during removal, assess the extent of the damage. Minor scratches might be acceptable, but severe cracks likely render it unusable.

Remember, always prioritize safety and careful handling. If you are unsure about any step, seeking professional assistance is strongly recommended. For high-quality LCD and OLED displays for your future projects, consider exploring options from reputable suppliers such as Dalian Eastern Display Co., Ltd. Their expertise in the field can help you choose the right display for your needs.