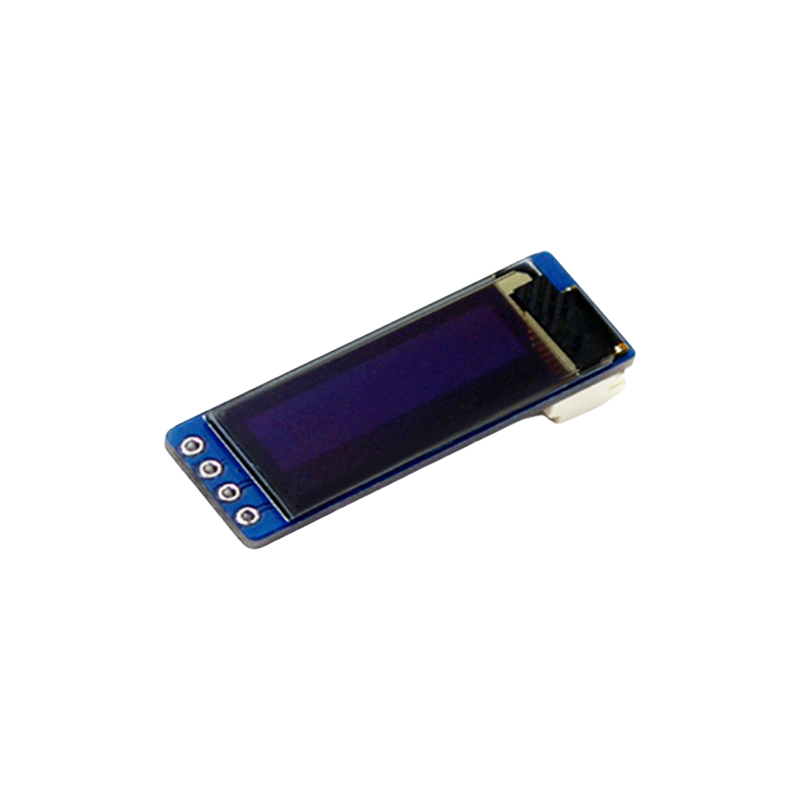

Building your own OLED display can be a rewarding project, offering unparalleled customization and control. However, finding the right best diy oled display factory is crucial for success. This guide will break down the key aspects to consider, ensuring you make an informed decision. The process involves more than just selecting a supplier; it requires understanding the technical specifications, potential limitations, and the overall manufacturing process. A successful outcome hinges on careful planning and the right partnership.

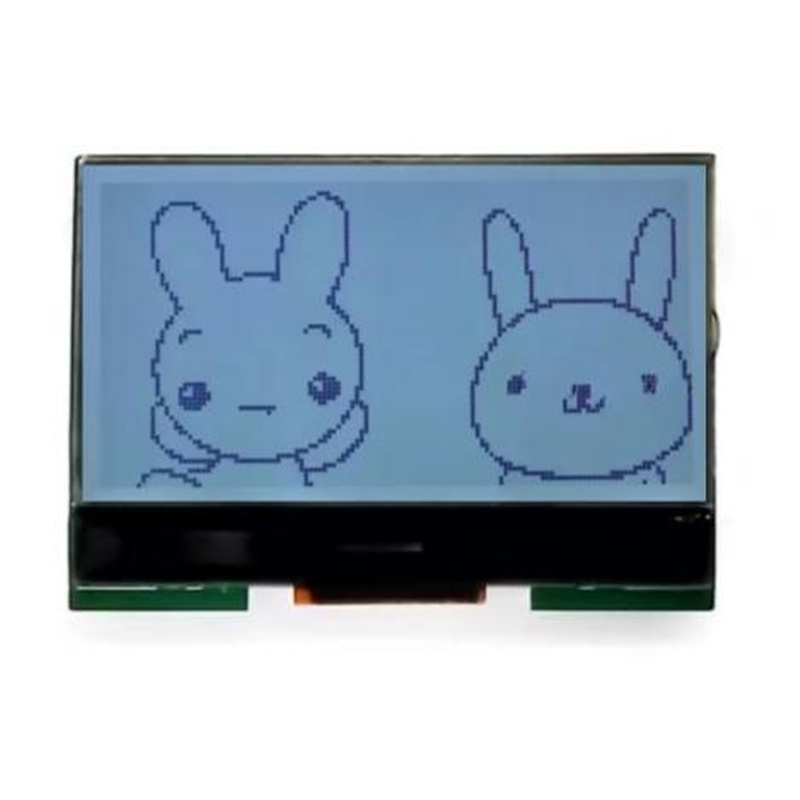

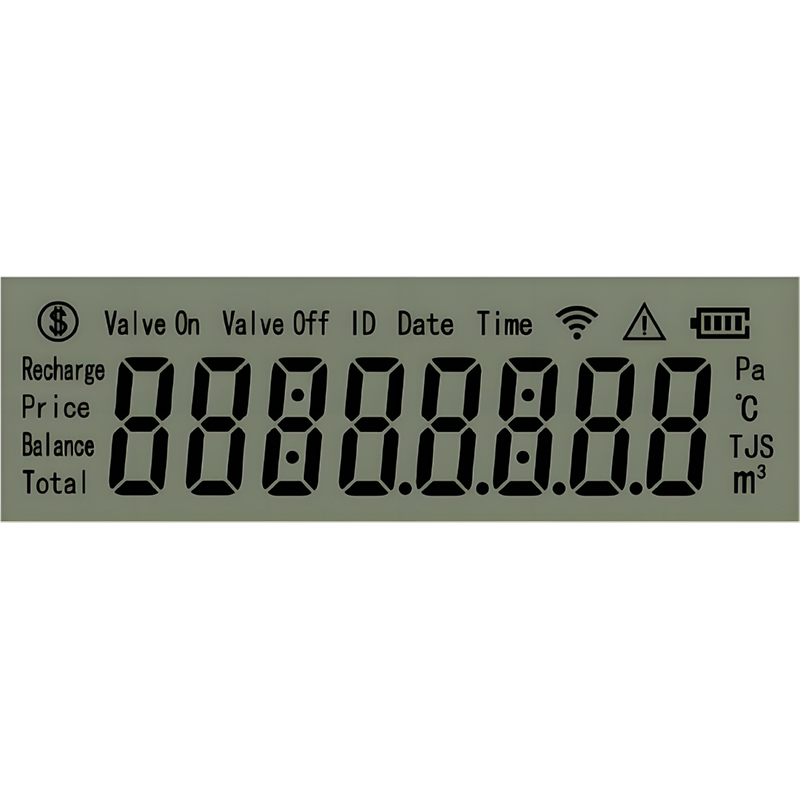

Before diving into finding a best diy oled display factory, understanding OLED technology is vital. Key specifications include resolution (measured in pixels), screen size (measured diagonally in inches), color depth (measured in bits), and refresh rate (measured in Hertz). Consider your project’s needs: high resolution for detailed images, larger sizes for immersive viewing, vibrant colors for captivating visuals, and a high refresh rate for smooth motion. Each specification impacts cost and complexity, so careful planning is essential.

OLED panels come in various types, each with strengths and weaknesses. AMOLED (Active-Matrix Organic Light-Emitting Diode) offers high contrast and excellent color accuracy, while PMOLED (Passive-Matrix Organic Light-Emitting Diode) is simpler and cheaper but has lower resolution and brightness. Your application will determine the ideal panel type. Remember to clearly specify your requirements when contacting potential best diy oled display factory.

When evaluating potential best diy oled display factory options, several key factors should guide your decision. These include:

Online directories and industry events are valuable resources for locating reputable best diy oled display factory. Thoroughly research potential suppliers, checking reviews and testimonials. Directly contacting several suppliers is recommended for comparative analysis. Don't hesitate to ask for references and case studies. Remember to always verify certifications and check for any negative reviews or complaints.

Building your own OLED display is challenging. Potential problems include variations in panel quality, difficulties with driver board integration, and potential screen burn-in. Working with a reliable best diy oled display factory helps mitigate these risks. Clear communication of requirements, detailed specifications, and rigorous testing at each stage are crucial.

A responsive best diy oled display factory will provide technical support throughout your project. This includes guidance on integration, troubleshooting, and addressing any unexpected issues. Ensure your chosen supplier offers adequate support and readily available resources.

Selecting the right best diy oled display factory is paramount for a successful DIY OLED display project. Careful consideration of technical specifications, supplier capabilities, and potential challenges ensures a smooth process and a high-quality outcome. Remember to thoroughly research, compare options, and prioritize communication to achieve your desired results. By following these guidelines, you can significantly increase your chances of a successful project.

| Feature | Dalian Eastern Display Co., Ltd. (https://www.ed-lcd.com/) | Competitor X |

|---|---|---|

| Minimum Order Quantity | (Insert MOQ from ed-lcd.com) | (Insert competitor data) |

| Lead Time | (Insert lead time from ed-lcd.com) | (Insert competitor data) |

| Customization Options | (Insert customization details from ed-lcd.com) | (Insert competitor data) |

Disclaimer: The information provided in this article is for general guidance only and should not be considered professional advice. Specific details and requirements may vary depending on your individual project. Always verify information with the relevant suppliers before making any decisions.