This comprehensive guide helps you navigate the world of dot matrix display factories, providing insights to select the perfect partner for your project. We'll explore key factors to consider, compare different manufacturers, and ultimately help you make an informed decision. Learn about various display types, production capabilities, and considerations for choosing the right supplier.

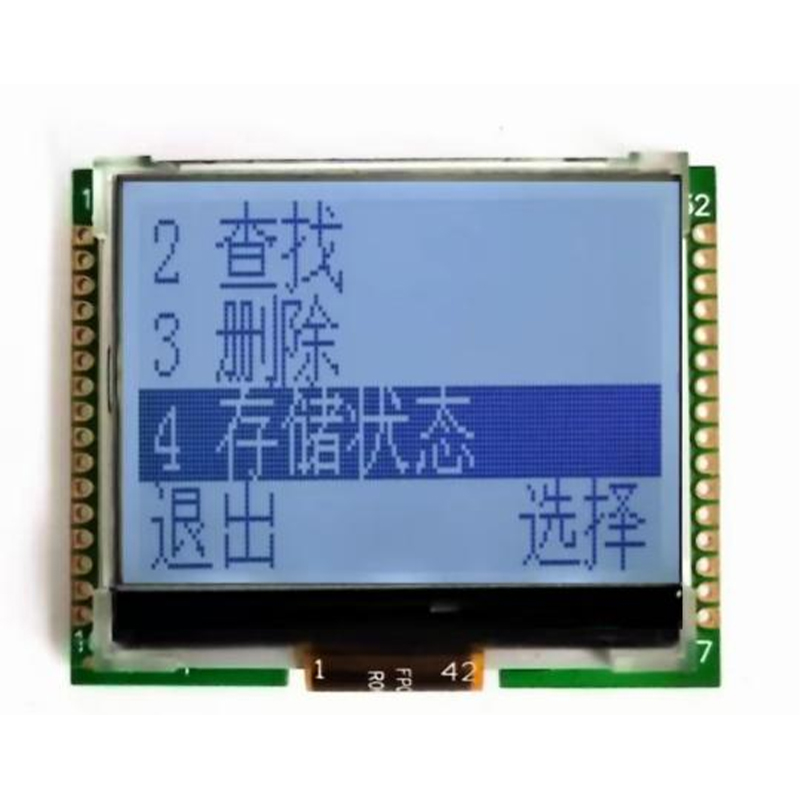

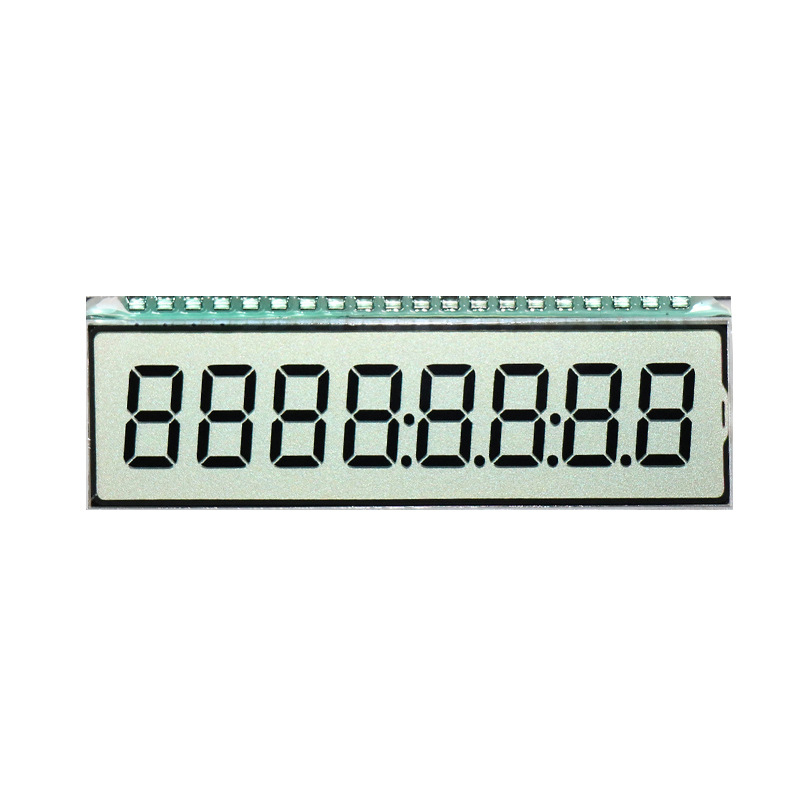

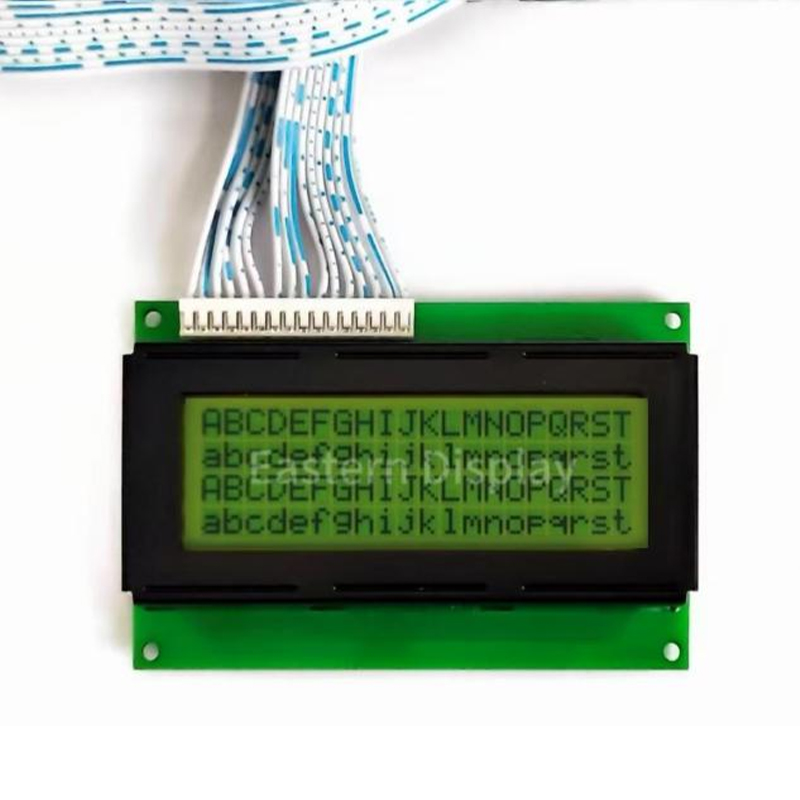

Dot matrix displays come in various configurations, including LED, LCD, and vacuum fluorescent displays (VFDs). Each technology offers unique advantages and disadvantages in terms of brightness, power consumption, cost, and lifespan. Understanding these differences is crucial for selecting the appropriate display for your specific application. For example, LED displays are known for their high brightness and energy efficiency, making them ideal for outdoor applications, while LCD displays are often preferred for indoor use due to their lower power consumption.

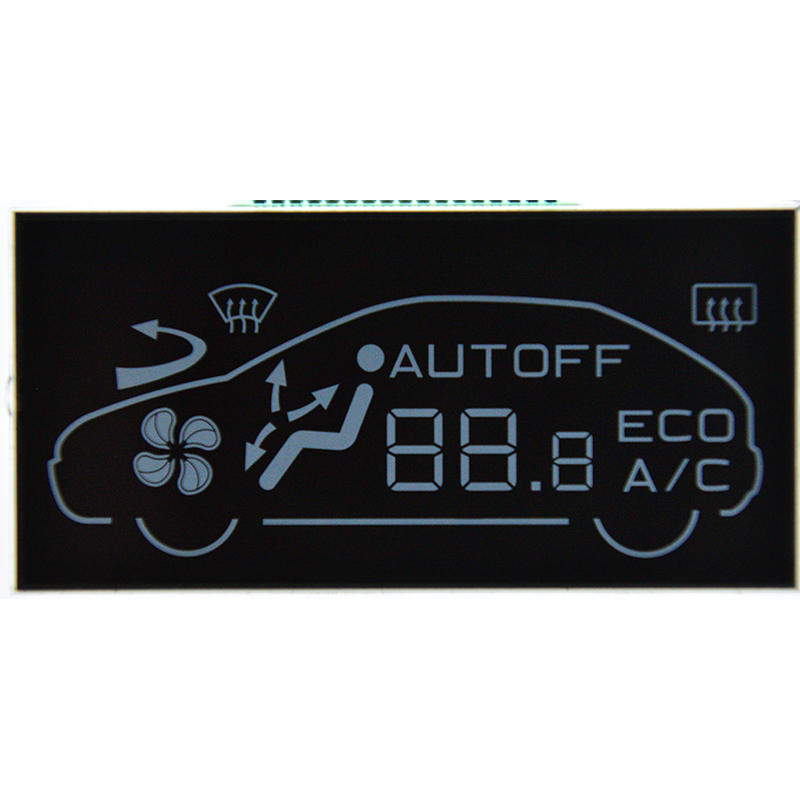

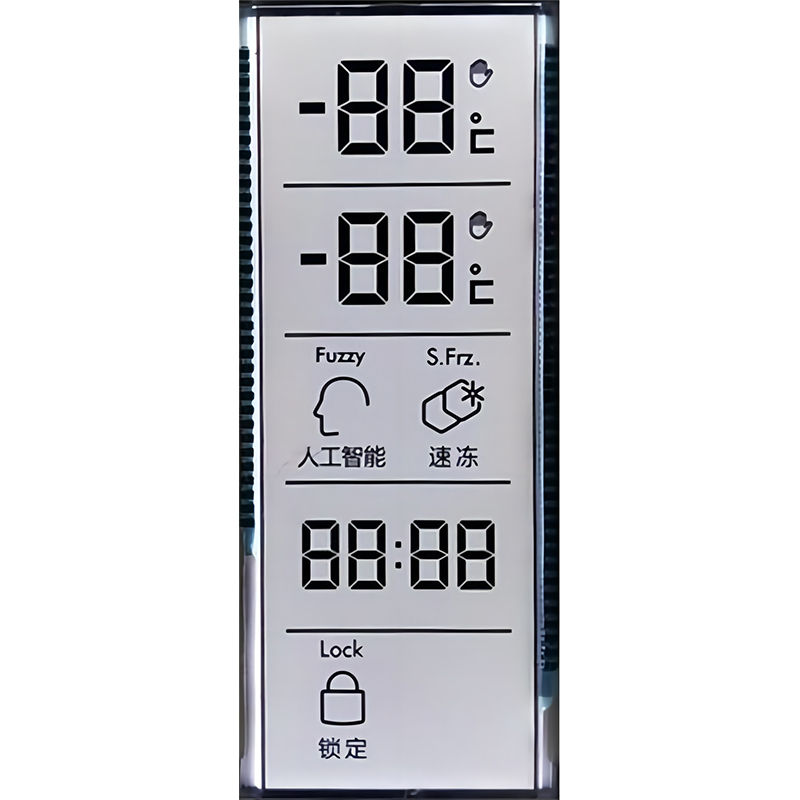

Dot matrix displays find widespread use in various industries. They are commonly employed in industrial control panels, automotive dashboards, consumer electronics, and medical equipment. The choice of display technology often depends on the specific requirements of the application. Factors such as size, resolution, viewing angle, and environmental conditions all play a crucial role in the selection process. Consider the durability required; some applications demand robustness in harsh environments.

Assess the factory's production capacity to ensure they can meet your order volume and deadlines. A reliable dot matrix display factory will be transparent about their production capabilities and lead times. Inquire about their minimum order quantity (MOQ) and their ability to handle both small and large-scale projects. Fast turnaround times are critical for projects with tight deadlines.

Look for factories with robust quality control processes and relevant certifications, such as ISO 9001. This demonstrates a commitment to producing high-quality displays that meet industry standards. Review customer testimonials and case studies to gauge the consistency and reliability of their products. Certifications indicate adherence to specific quality management systems.

If your project requires custom designs or modifications, ensure the dot matrix display factory offers design support and customization options. A reputable factory will have experienced engineers who can assist with the design and development process. This support can prove invaluable in translating your requirements into a functional and aesthetically pleasing product. Discuss your design needs early in the selection process.

Obtain detailed pricing information and clarify payment terms upfront. Compare quotes from multiple factories to ensure you are receiving competitive pricing. Be wary of extremely low prices, as they may indicate compromised quality or hidden costs. Transparency in pricing and payment terms is crucial.

Several factors influence the selection of a dot matrix display factory. The following table summarizes key aspects to compare different suppliers:

| Factory Name | Production Capacity | MOQ | Certifications | Customization Options | Lead Time (Typical) |

|---|---|---|---|---|---|

| Factory A | High | 1000 | ISO 9001 | Yes | 4-6 weeks |

| Factory B | Medium | 500 | ISO 9001, RoHS | Yes | 6-8 weeks |

| Factory C | Low | 200 | None | Limited | 8-10 weeks |

| Dalian Eastern Display Co., Ltd. | High | Negotiable | ISO 9001, IATF 16949 | Extensive | Contact for quote |

Selecting the right dot matrix display factory is crucial for the success of your project. By carefully considering the factors outlined above and performing thorough due diligence, you can choose a reliable partner that meets your quality, production, and budgetary requirements. Remember to always compare multiple suppliers and thoroughly review their capabilities before making your final decision.

Remember to verify all information with the respective manufacturer's websites.