This comprehensive guide helps you navigate the landscape of dot matrix display programming factories, outlining key considerations for selecting the right partner for your project. We'll explore crucial factors such as expertise, capabilities, and quality control, ultimately guiding you towards a successful collaboration. Learn about various technologies, common challenges, and best practices for ensuring a smooth and efficient production process.

Before embarking on your search for a best dot matrix display programming factory, clearly define your project requirements. This includes the display's size, resolution, type (LED, LCD, etc.), desired brightness, viewing angle, and any specific functionalities needed. Consider the application – is it for industrial control, consumer electronics, or something else? A clear understanding of these details is paramount in selecting a factory with the appropriate expertise.

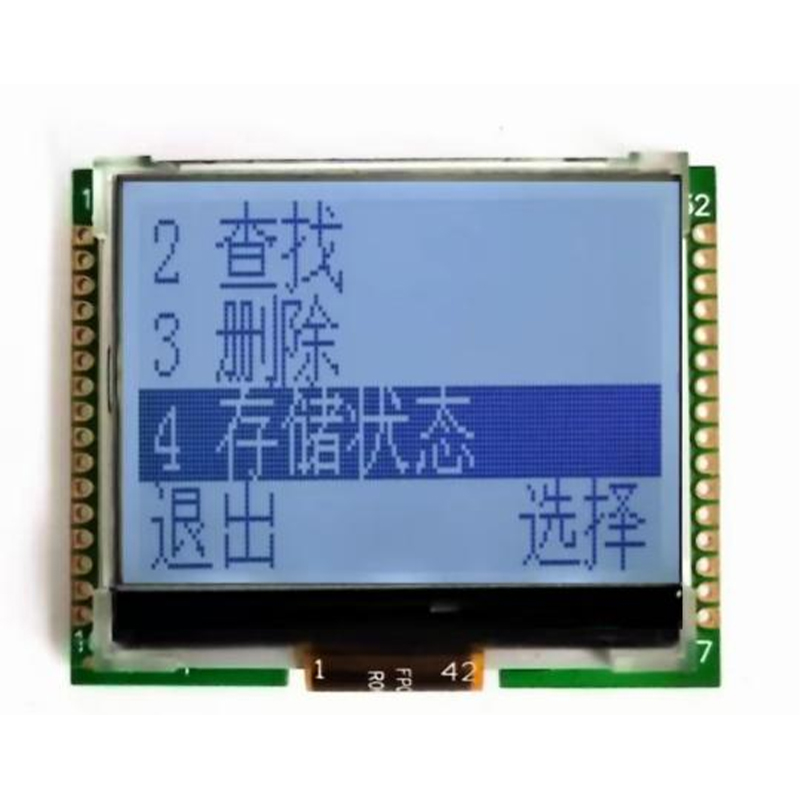

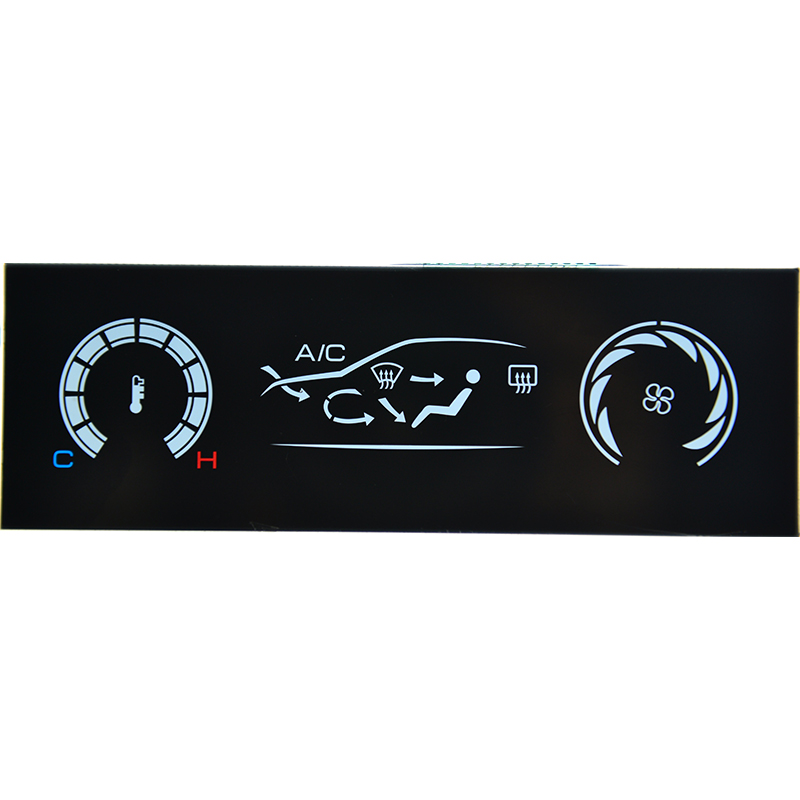

Different technologies offer varied advantages and disadvantages. LED dot matrix displays are known for their brightness and durability, while LCD displays often offer better contrast and color options. Your choice will depend heavily on your application’s specific needs. Consider factors like power consumption, longevity, and cost when making your decision. Research different types of dot matrix displays to understand their capabilities fully.

Investigate the factory's production capacity, equipment, and experience with your specific dot matrix display requirements. Look for factories that can handle your desired volume while maintaining high quality standards. Do they utilize advanced technologies? Do they have a proven track record of successful projects? Inquire about their quality control processes, including testing methodologies and defect rates.

A reputable best dot matrix display programming factory will have robust quality control measures in place. This includes rigorous testing at various stages of production to ensure consistent quality and reliability. Ask about their certifications (ISO 9001, for instance) and their approach to addressing potential issues. Transparency and a proactive approach to quality are crucial indicators of a reliable partner.

Effective communication is key to a successful project. Choose a factory that is responsive, provides regular updates, and is open to collaboration. A seamless flow of information is vital for addressing any challenges promptly and ensuring the project stays on track. Investigate their communication channels and the ease of reaching their team.

Once you've narrowed down your options, compare the shortlisted factories based on your criteria. Consider factors like price, lead times, and the overall value proposition. Remember, the lowest price isn't always the best option; prioritize quality, reliability, and a strong working relationship. A thorough evaluation will ensure you choose the best dot matrix display programming factory to meet your project needs.

One example of a successful partnership involves [Client Name], who partnered with Dalian Eastern Display Co., Ltd. (https://www.ed-lcd.com/) for their [Project Type] project. Dalian Eastern Display's expertise in dot matrix display programming, coupled with their commitment to quality and efficient communication, resulted in a highly successful outcome. This collaboration highlights the importance of choosing a factory that understands your unique requirements and provides dedicated support throughout the entire process.

| Feature | Factory A | Factory B |

|---|---|---|

| Production Capacity | 10,000 units/month | 5,000 units/month |

| Lead Time | 4 weeks | 6 weeks |

| Quality Certifications | ISO 9001 | None |

Remember to thoroughly research and carefully select your best dot matrix display programming factory. This comprehensive approach will ensure a successful project and a strong, long-term partnership.