Choosing the right Best g oled display factory is crucial for any project involving OLED displays. This decision impacts product quality, cost-effectiveness, and timely delivery. This guide provides a thorough overview of key considerations, helping you navigate the complexities of the OLED display manufacturing landscape and select a partner that aligns perfectly with your requirements. We'll delve into the technological aspects of OLED production, examine key quality metrics, and explore several leading manufacturers, allowing you to make a well-informed choice for your specific needs.

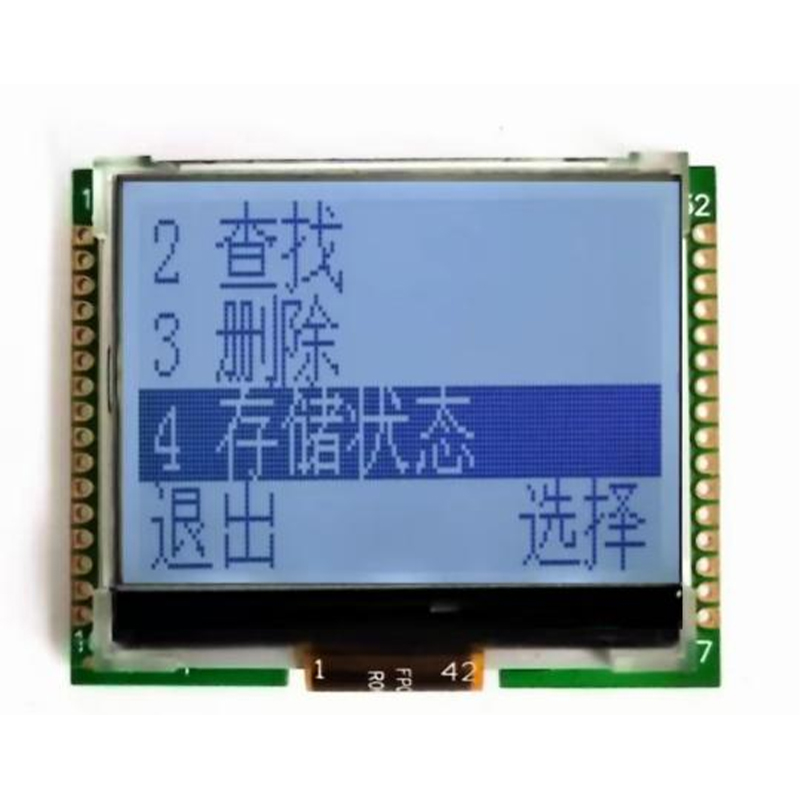

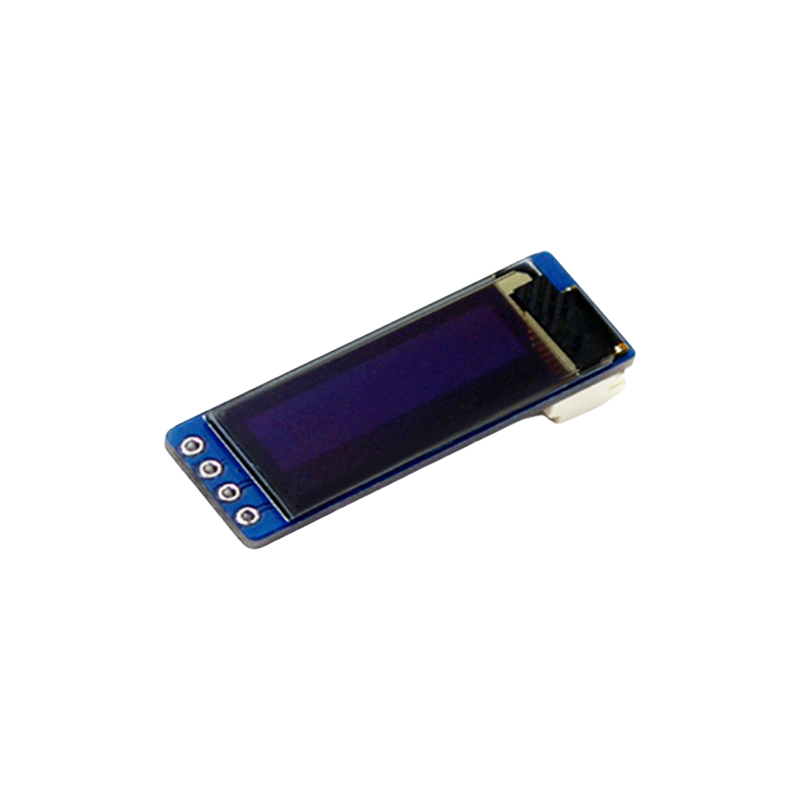

Before diving into factory selection, understanding OLED technology is essential. Organic Light-Emitting Diodes (OLEDs) are self-emissive displays, meaning each pixel generates its own light. This contrasts with LCDs, which require a backlight. This difference leads to superior image quality, with deeper blacks, vibrant colors, and wider viewing angles. Different OLED technologies exist, including AMOLED (Active-Matrix OLED) commonly used in smartphones and TVs, and WOLED (White OLED) often found in larger displays. Understanding these variations is key to matching your needs with the capabilities of a specific Best g oled display factory.

The factory's production capacity directly impacts your project timeline and ability to meet demand. Consider the factory's ability to scale production to match your future needs. A factory capable of handling large-scale production is vital for larger projects.

Stringent quality control is paramount. Look for factories with established quality management systems (QMS) and relevant certifications, such as ISO 9001. Rigorous testing ensures consistent product quality and minimizes defects.

The factory's technological capabilities and commitment to innovation are critical. Choose a factory that stays at the forefront of OLED technology, ensuring access to the latest advancements and improvements.

The ability to customize displays to meet specific requirements is a significant advantage. Consider the factory's flexibility to adapt to your unique specifications, including size, resolution, and other features. Some factories specialize in smaller, niche applications while others focus on mass production for larger clients.

The factory's location influences logistical costs and lead times. Evaluate the proximity to your target market and assess the efficiency of the supply chain. Consider factors like shipping costs and potential delays.

Obtain clear and detailed pricing information, including any potential hidden costs. Negotiate favorable payment terms that align with your financial capabilities.

While providing a definitive best factory is impossible without knowing your specific needs, several manufacturers consistently rank highly for their quality and capabilities. Researching these companies is a crucial step. Remember to always verify information with the manufacturers directly.

| Factory | Specialization | Key Features | Contact |

|---|---|---|---|

| Dalian Eastern Display Co., Ltd. https://www.ed-lcd.com/ | High-quality OLED displays for various applications | Advanced manufacturing capabilities, customization options, stringent quality control | [Contact information available on their website] |

| [Insert another reputable manufacturer] | [Their specialization] | [Their key features] | [Their contact information] |

| [Insert another reputable manufacturer] | [Their specialization] | [Their key features] | [Their contact information] |

This table is not exhaustive, and other excellent Best g oled display factory options exist. Always conduct thorough due diligence before selecting a partner.

Remember to consider all factors discussed above before making your final decision. Selecting the right Best g oled display factory ensures your project's success.