This comprehensive guide helps you navigate the complexities of choosing a Best High Contrast LCD factory. We explore key factors to consider, including contrast ratio specifications, manufacturing capabilities, and quality control measures. Learn how to identify a reputable supplier that meets your specific project requirements and budget.

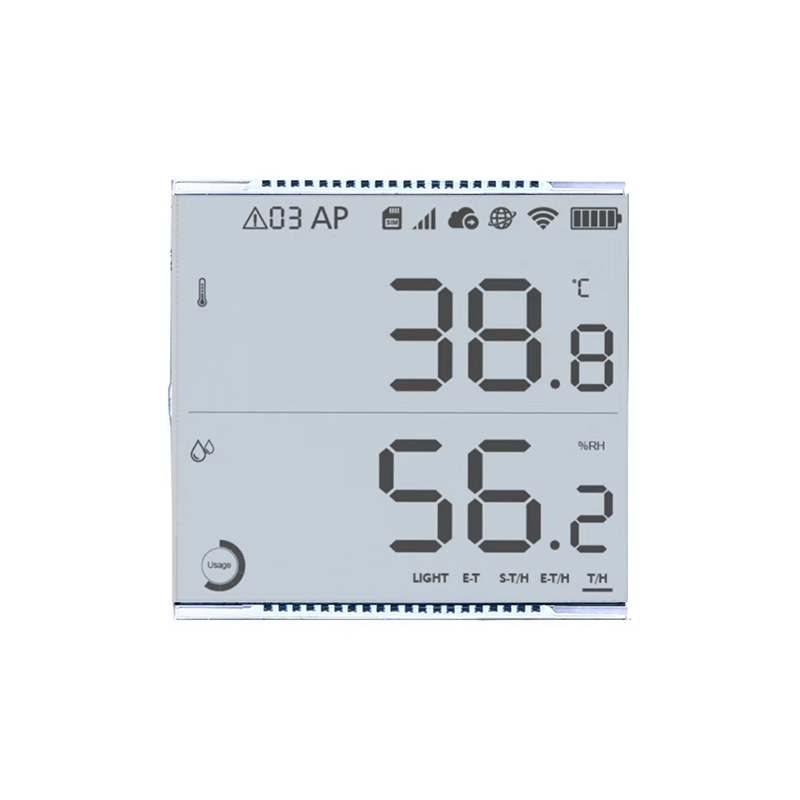

High contrast in an LCD refers to the difference in luminance between the brightest white and the darkest black the screen can produce. A higher contrast ratio generally results in a more vibrant and detailed image, with deeper blacks and brighter whites. This is crucial for applications requiring sharp visuals, such as medical imaging, professional displays, and high-end gaming monitors. The contrast ratio is usually expressed as a numerical value (e.g., 1000:1, 10000:1). Higher numbers indicate better contrast.

Several technologies contribute to high contrast LCDs. These include IPS (In-Plane Switching), VA (Vertical Alignment), and OLED (Organic Light Emitting Diode) technologies, each with its strengths and weaknesses in terms of contrast, viewing angles, and response time. Choosing the right technology depends on your specific application demands. For example, IPS is often praised for its wide viewing angles, while VA panels typically offer higher contrast ratios.

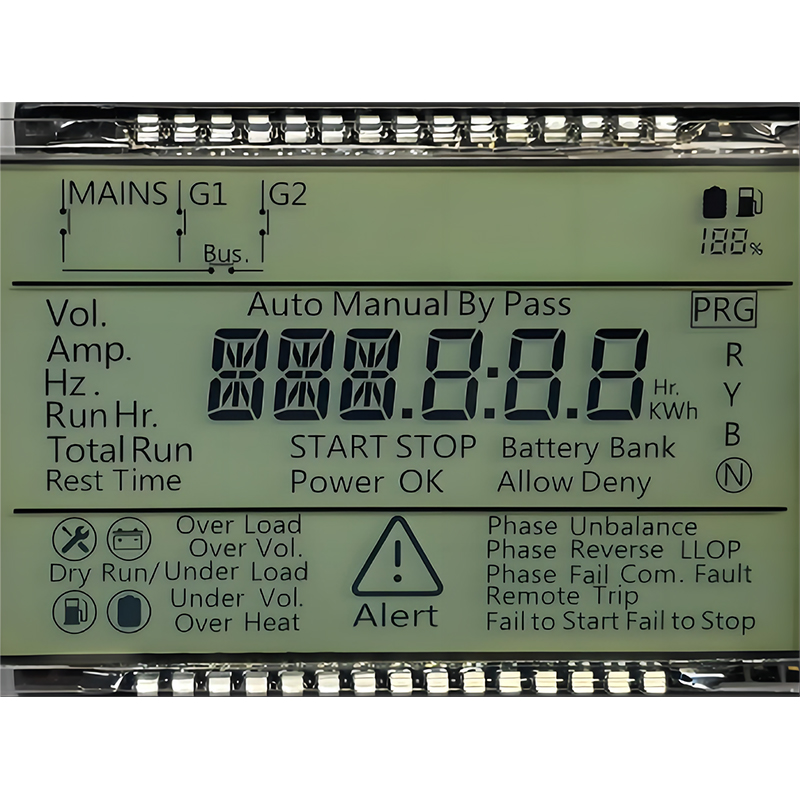

Clearly defined contrast ratio specifications are paramount. Verify the factory's claims through independent testing or verification reports. Ensure the specifications align with your project’s needs and understand the testing methodologies employed to obtain these values. Look for factories that provide detailed data sheets and specifications for their Best High Contrast LCD products.

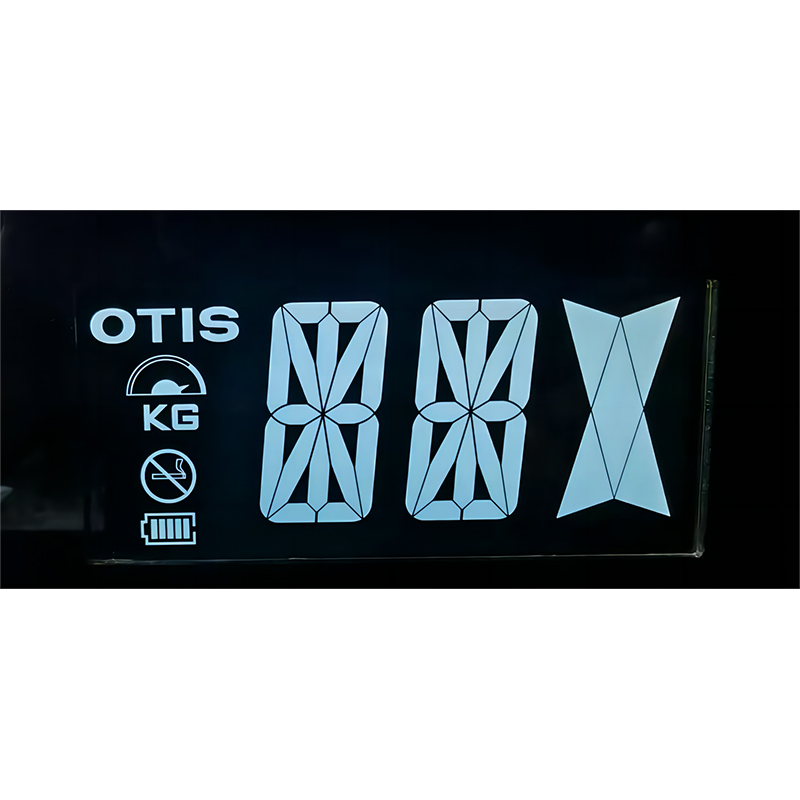

Assess the factory's manufacturing capabilities, including production volume, customization options, and technological advancements. Consider whether they can meet your current and future needs. A scalable factory can adapt to changing demands and project requirements.

A reputable Best High Contrast LCD factory will implement stringent quality control measures. Look for ISO certifications (ISO 9001 for quality management systems, for example) and other industry-recognized quality standards. These certifications demonstrate commitment to consistent quality and reliability.

Research the factory's history, track record, and client testimonials. Look for evidence of successful projects and satisfied customers. Online reviews and industry publications can provide valuable insights into a factory’s reputation and reliability.

Compare pricing from multiple factories and negotiate favorable terms. Consider not just the initial cost but also potential ongoing costs such as maintenance and support. Be sure to clarify delivery timelines and potential delays. Transparency in pricing and shipping is crucial.

Finding the right partner requires thorough due diligence. Utilize online resources, industry directories, and trade shows to identify potential suppliers. Direct communication with multiple factories is recommended to compare their offerings and assess their suitability for your project. Consider visiting potential factories in person to conduct thorough inspections and evaluations.

Dalian Eastern Display Co., Ltd. (https://www.ed-lcd.com/) is a leading manufacturer of high-quality LCD displays. They offer a wide range of products and customization options. You can contact them to discuss your specific needs and explore their capabilities in providing Best High Contrast LCD solutions.

Selecting the Best High Contrast LCD factory involves careful consideration of various factors. By understanding the nuances of LCD technology, evaluating supplier capabilities, and implementing a thorough selection process, you can ensure a successful partnership and high-quality end product. Remember to prioritize quality, reliability, and a strong partnership with your chosen manufacturer.