This guide provides comprehensive troubleshooting and solutions for common issues encountered when using I2C 1602 LCD modules, focusing on effective exit strategies when your code encounters errors or unexpected behavior. We’ll cover various scenarios, providing practical solutions backed by real-world examples and best practices.

The I2C protocol simplifies communication between your microcontroller and the I2C 1602 LCD module. However, issues such as incorrect wiring, addressing conflicts, or software glitches can lead to problems. A robust exit strategy in your code is crucial for graceful handling of these situations. Before diving into exit strategies, let's briefly review the essential components:

A typical I2C 1602 LCD module setup requires the following:

Ensure correct wiring – incorrect connections can damage your components. Refer to your specific microcontroller and I2C 1602 LCD module datasheets for detailed pinouts. Double-check the I2C address of your module, as conflicts with other devices can disrupt communication.

Several problems can arise when working with I2C 1602 LCD modules. Let’s explore some common issues and effective exit strategies.

If the microcontroller fails to communicate with the LCD, a simple retry mechanism with a timeout can be implemented. This prevents the program from hanging indefinitely. If the retries fail, an appropriate error message can be logged, or an alternative display method can be used.

Specifying the wrong I2C address will prevent communication. A robust solution involves checking the address configuration of your I2C 1602 LCD module. Some modules may have address jumpers, while others require software configuration. If the address is incorrectly configured, your program should ideally handle this gracefully, perhaps logging an error.

Hardware faults can cause unpredictable behavior. Implementing checks for communication success (e.g., acknowledging the LCD's response) can prevent your program from crashing in case of a hardware failure. In such scenarios, a graceful exit, perhaps with an error message indicating a likely hardware failure, should be considered.

Writing robust code for I2C 1602 LCD module interaction involves several key best practices.

Implement comprehensive error handling mechanisms to catch exceptions, handle communication failures, and provide informative error messages. Logging errors allows for easier debugging and troubleshooting.

Using timeouts prevents your program from getting stuck in an infinite loop if communication fails. Setting appropriate timeout periods ensures responsive behavior.

Breaking down your code into smaller, well-defined functions improves readability and makes it easier to identify and fix issues. This modular design also simplifies the implementation of exit strategies.

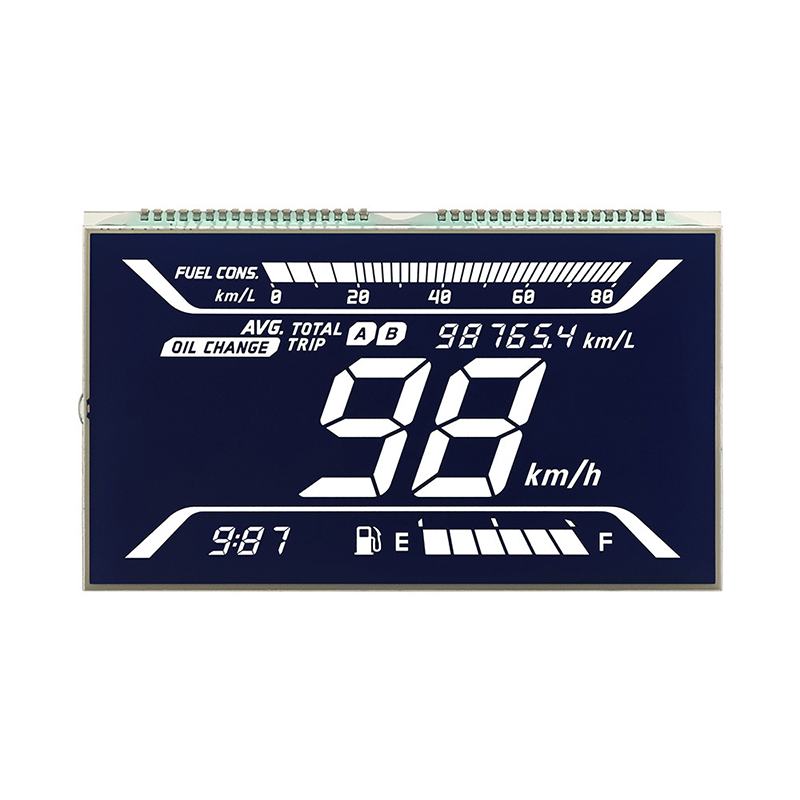

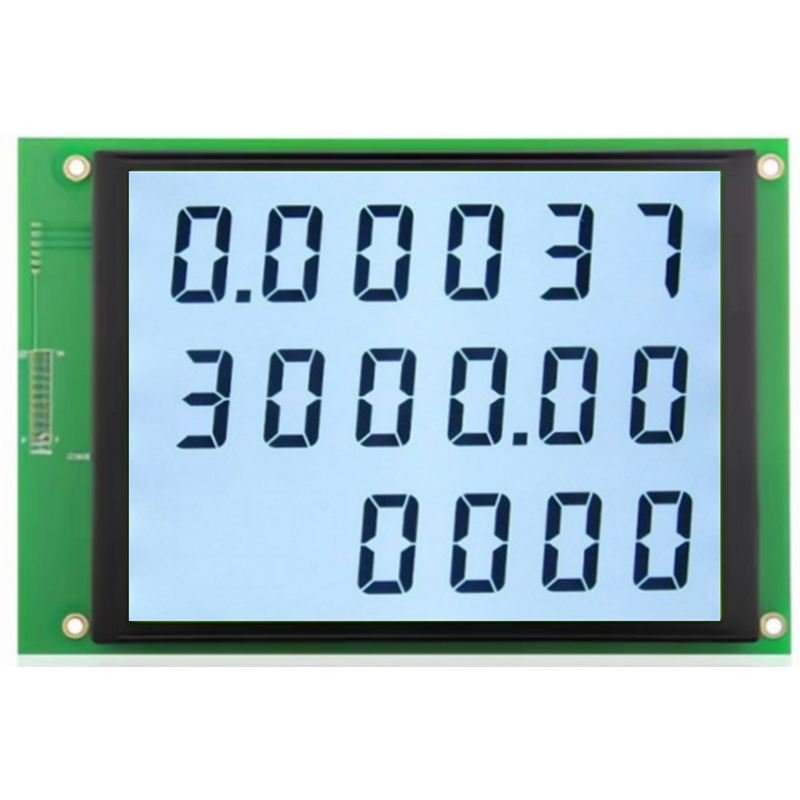

The quality and specifications of your I2C 1602 LCD module can significantly impact your project's success. Consider factors like backlight type, contrast adjustment, and overall build quality when making your selection. For high-quality LCD modules and excellent customer support, consider checking out Dalian Eastern Display Co., Ltd., a leading supplier of LCD display solutions.

| Feature | Module A | Module B |

|---|---|---|

| Backlight | White LED | Blue LED |

| Contrast Adjustment | Potentiometer | Software |

| Operating Voltage | 5V | 3.3V |

Remember to always consult the datasheets for your specific microcontroller and I2C 1602 LCD module for accurate pinouts and specifications.