This comprehensive guide helps you navigate the complexities of selecting a Best i2c spi interface factory. We'll explore key considerations, compare different manufacturing approaches, and offer insights to help you make an informed decision for your specific needs. Learn about the crucial factors influencing performance, reliability, and cost-effectiveness.

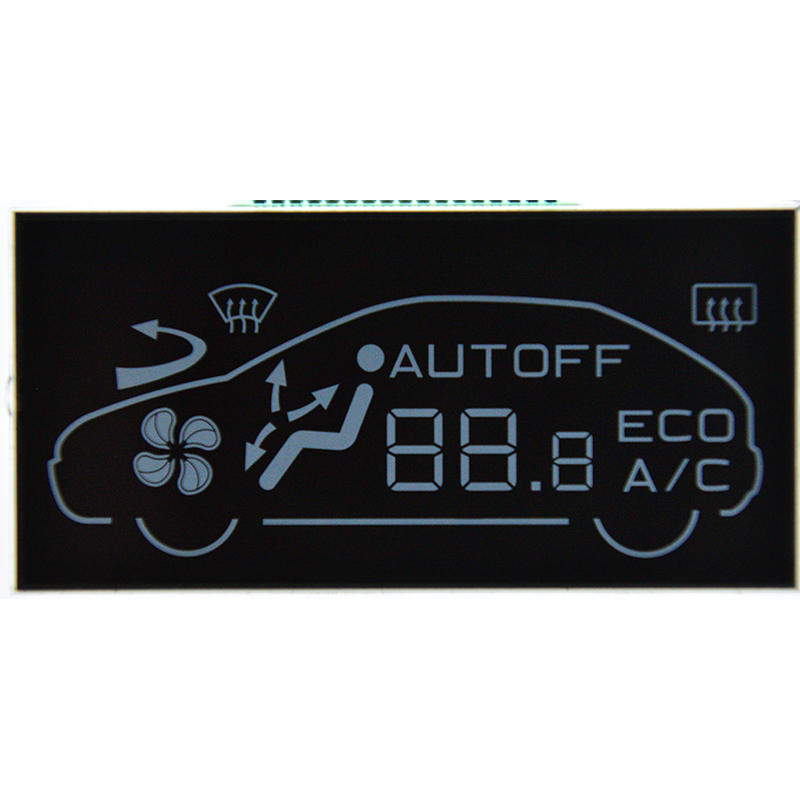

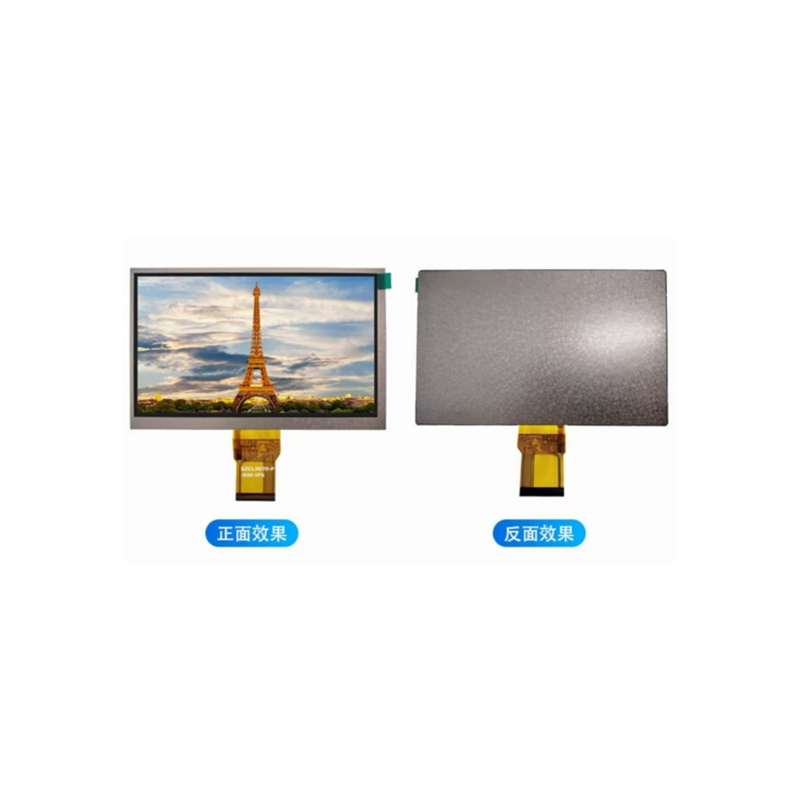

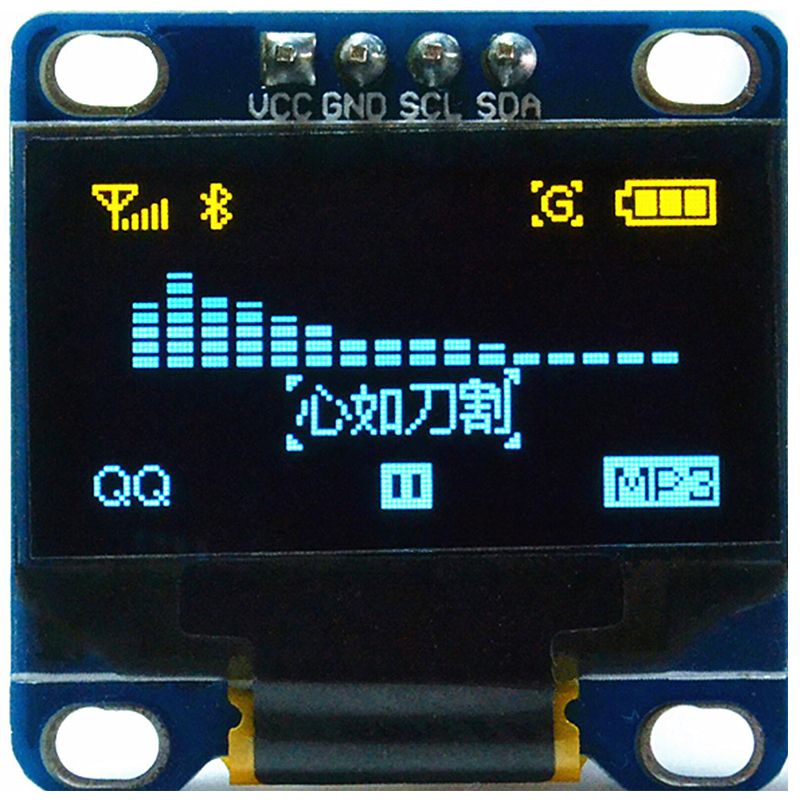

I2C (Inter-Integrated Circuit) is a simple, multi-master, single-ended, serial communication bus. It's widely used for short-distance communication, requiring only two wires: SDA (data) and SCL (clock). Its ease of implementation makes it popular in various embedded systems. Consider its lower speed compared to SPI for high-bandwidth applications.

SPI (Serial Peripheral Interface) is a full-duplex, synchronous, master-slave serial communication protocol. It offers higher speeds and greater throughput than I2C, making it ideal for applications demanding high data transfer rates. However, it requires more pins than I2C.

The choice between I2C and SPI depends heavily on your project's requirements. I2C is suitable for simpler applications with lower bandwidth demands, while SPI excels in scenarios requiring higher speeds and data throughput. Factors like the number of devices, data rate requirements, and power consumption should inform your selection.

A reliable Best i2c spi interface factory should have the capacity to meet your current and future production needs. Scalability is crucial to accommodate growth without compromising quality or delivery times. Look for factories with flexible production lines and a proven track record of handling large-scale projects.

Rigorous quality control is paramount. Ensure the factory adheres to industry standards and possesses relevant certifications (e.g., ISO 9001). Thorough quality checks at various stages of production minimize defects and ensure consistent product reliability.

A forward-thinking factory will possess expertise in the latest technologies and manufacturing processes. Look for a partner who can offer innovative solutions and stay ahead of industry trends. Their ability to adapt to evolving demands is crucial for long-term collaboration.

While cost is a significant factor, prioritize a balance between price and quality. Inquire about lead times and payment terms to ensure they align with your project timeline and budget. Hidden costs should be clearly understood upfront.

1. Define Your Requirements: Clearly outline your specifications, including I2C/SPI interface type, required features, production volume, and quality standards.

2. Research Potential Factories: Use online resources and industry directories to identify potential suppliers. Consider factors like geographic location and logistical considerations.

3. Request Quotes and Samples: Request detailed quotes from multiple factories and obtain samples to evaluate quality and performance.

4. Conduct Site Visits (if possible): On-site inspections allow you to assess the factory's facilities, production processes, and quality control measures firsthand.

5. Negotiate Contracts and Terms: Carefully review contracts and ensure all aspects are clearly defined before finalizing your agreement. Dalian Eastern Display Co., Ltd. (https://www.ed-lcd.com/) offers a wide range of display solutions, and you may find their expertise valuable during this process.

| Factory | Capacity | Certifications | Lead Time (weeks) | Price Range |

|---|---|---|---|---|

| Factory A | High | ISO 9001, ISO 14001 | 4-6 | $X - $Y |

| Factory B | Medium | ISO 9001 | 6-8 | $Z - $W |

| Factory C | Low | None | 8-10 | $A - $B |

Note: This is a sample table. Replace with actual data from your research.

Choosing the Best i2c spi interface factory requires careful consideration of various factors. By following this guide and conducting thorough research, you can make an informed decision that meets your project's specific needs and ensures a successful outcome. Remember to always verify information and request samples before committing to a long-term partnership.