Converting data between I2C and SPI interfaces is a common requirement in embedded systems. This guide explores the best methods to achieve this conversion, covering both hardware and software solutions, while considering factors like speed, complexity, and cost. We'll examine various techniques, highlighting their advantages and disadvantages to help you choose the optimal approach for your specific application.

Before delving into interface conversion, it's crucial to understand the fundamental differences between I2C and SPI protocols. I2C (Inter-Integrated Circuit) is a multi-master, serial communication bus commonly used for low-speed data transfer. SPI (Serial Peripheral Interface) is a synchronous, full-duplex communication protocol known for its high-speed data transfer capabilities. The need for a best I2C to SPI interface solution arises from the incompatibility between these protocols, necessitating a conversion mechanism.

I2C utilizes a two-wire system (SDA and SCL) for data and clock signals. It employs a master-slave architecture, where one master device controls the communication process. Its simplicity and low cost make it ideal for smaller, less demanding applications. However, its lower speed compared to SPI limits its suitability for high-bandwidth scenarios.

SPI, on the other hand, employs four wires (MOSI, MISO, SCK, and SS) for data transmission and clock synchronization. It supports higher data transfer rates than I2C due to its full-duplex nature and synchronous clocking. While offering superior speed, it typically requires more complex hardware implementation.

Several methods exist for converting data between I2C and SPI, each with its pros and cons. The best choice depends heavily on the specific application requirements and constraints. Let's examine some popular approaches:

Many dedicated ICs provide direct I2C to SPI conversion. These chips often offer features like level shifting and buffering, simplifying the integration process. Examples include various chips from manufacturers like Texas Instruments and Maxim Integrated. Choosing the right chip requires careful consideration of factors like data rate, bus voltage, and power consumption. The selection should also consider potential issues like signal integrity at higher speeds.

Microcontrollers (MCUs) with built-in I2C and SPI peripherals offer a flexible and cost-effective solution. Using firmware, you can program the MCU to read data from the I2C bus and then transmit it over the SPI bus, and vice-versa. This approach is ideal for applications where flexibility is crucial, allowing for custom protocol handling and data manipulation. However, it increases the software development burden and may limit the achievable data transfer rate due to processing overhead. Careful attention to timing and interrupt handling is critical for successful implementation.

For high-performance and customized I2C to SPI interface applications, FPGAs offer a powerful alternative. Their inherent flexibility enables the implementation of complex data conversion logic and protocols. However, this approach necessitates specialized knowledge and tools for FPGA programming and can be more resource-intensive than other methods.

| Method | Advantages | Disadvantages |

|---|---|---|

| Hardware Converter IC | Simple implementation, high speed | Higher cost, limited flexibility |

| Microcontroller-Based | Cost-effective, flexible | Requires software development, potentially lower speed |

| FPGA | High performance, highly customizable | High cost, complex implementation |

The optimal approach for a best I2C to SPI interface depends on factors like speed requirements, cost constraints, and the level of customization needed. For high-speed applications, a dedicated hardware converter might be preferable. For applications requiring flexibility and cost-effectiveness, a microcontroller-based solution may be more suitable. For highly demanding applications needing extensive customization, an FPGA offers the highest performance potential.

Remember to always consult the datasheets of the chosen components for specific details and instructions. Careful consideration of signal integrity and timing is critical for successful implementation of any of these solutions. For more advanced applications, considering adding error correction mechanisms can enhance the reliability of your I2C to SPI interface.

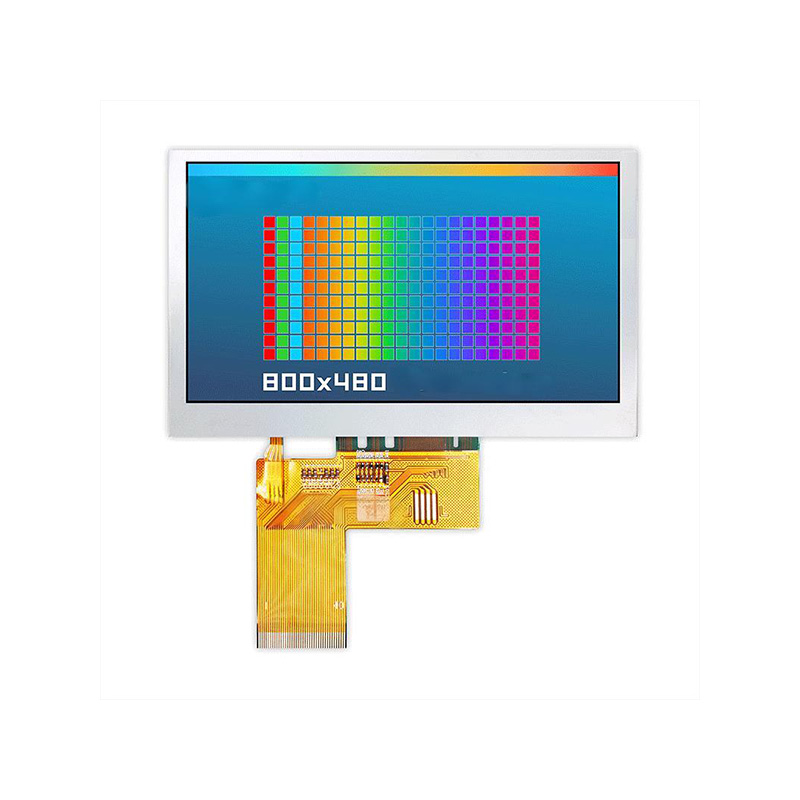

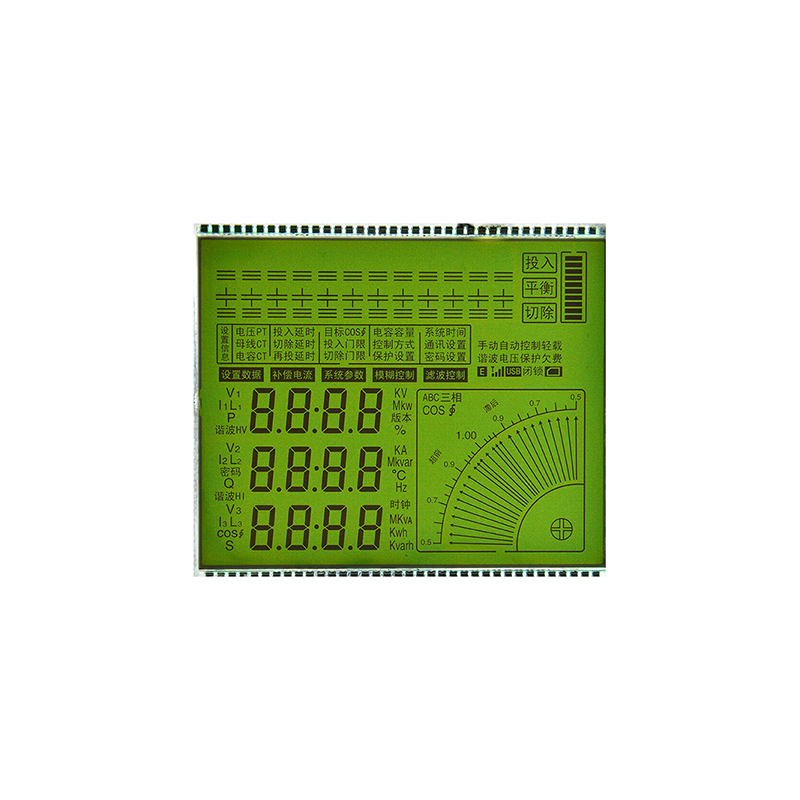

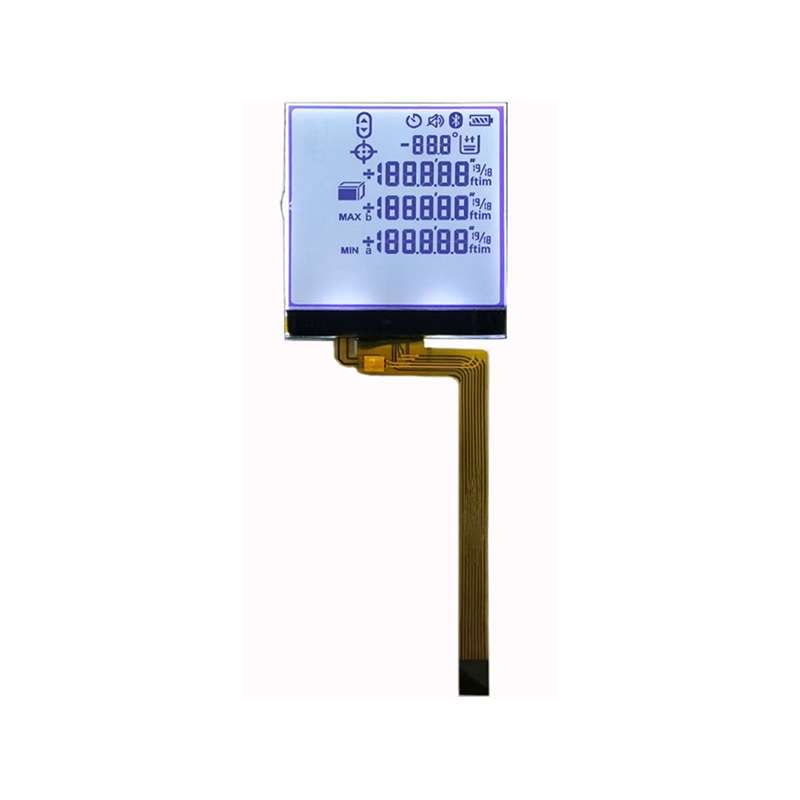

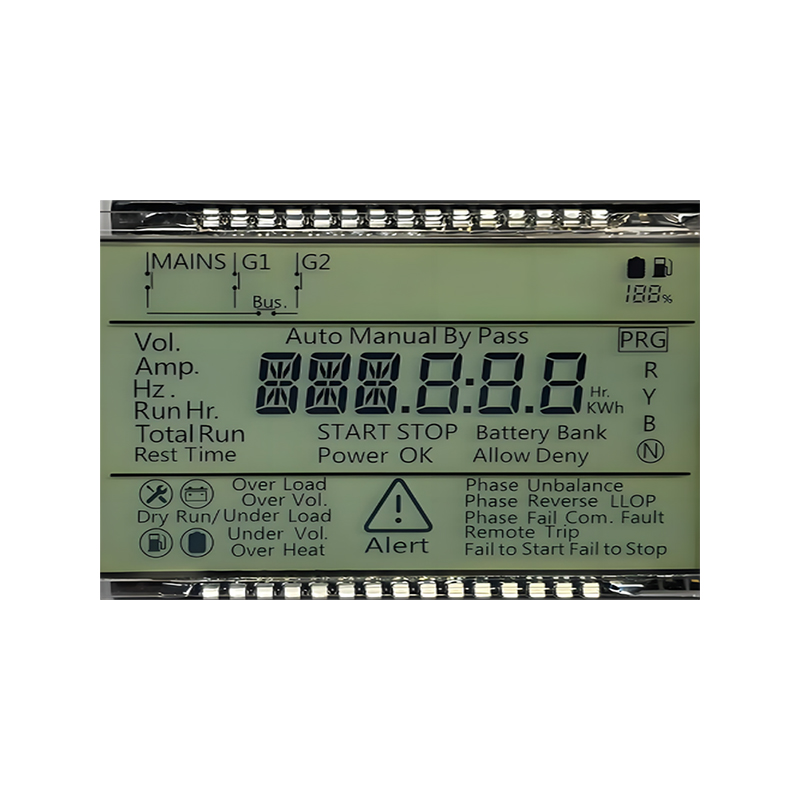

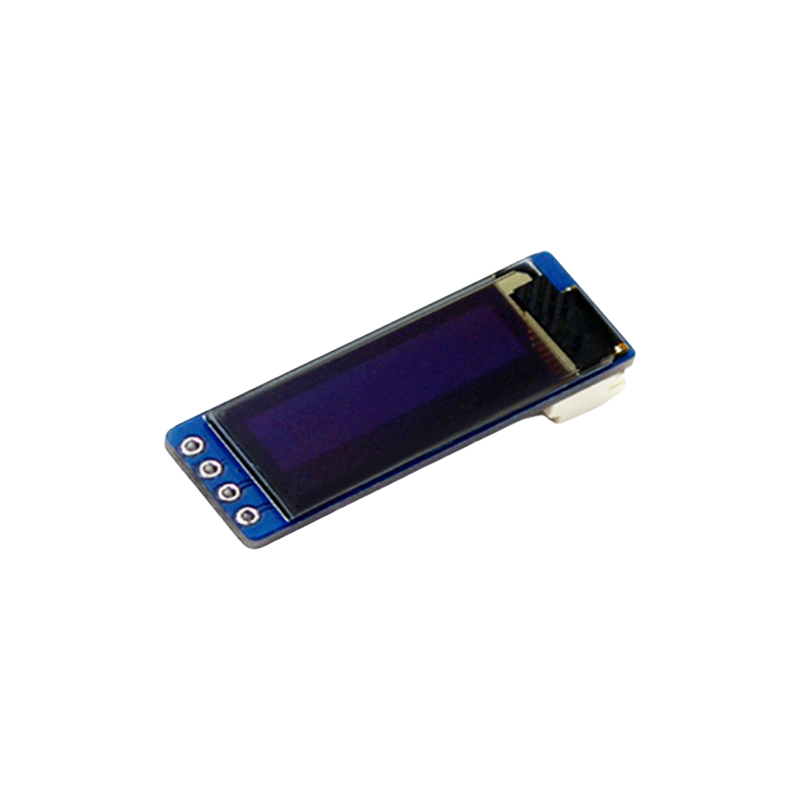

For high-quality LCD displays to integrate into your projects, consider exploring the offerings from Dalian Eastern Display Co., Ltd. They provide a wide range of display solutions for various applications.