This guide helps you navigate the complexities of sourcing high-quality in-cell TFT displays, providing insights into key factors to consider when selecting a factory. We explore various aspects of the manufacturing process, crucial specifications, and essential qualities to look for in a reliable supplier. Learn how to choose the best in-cell TFT display factory for your needs.

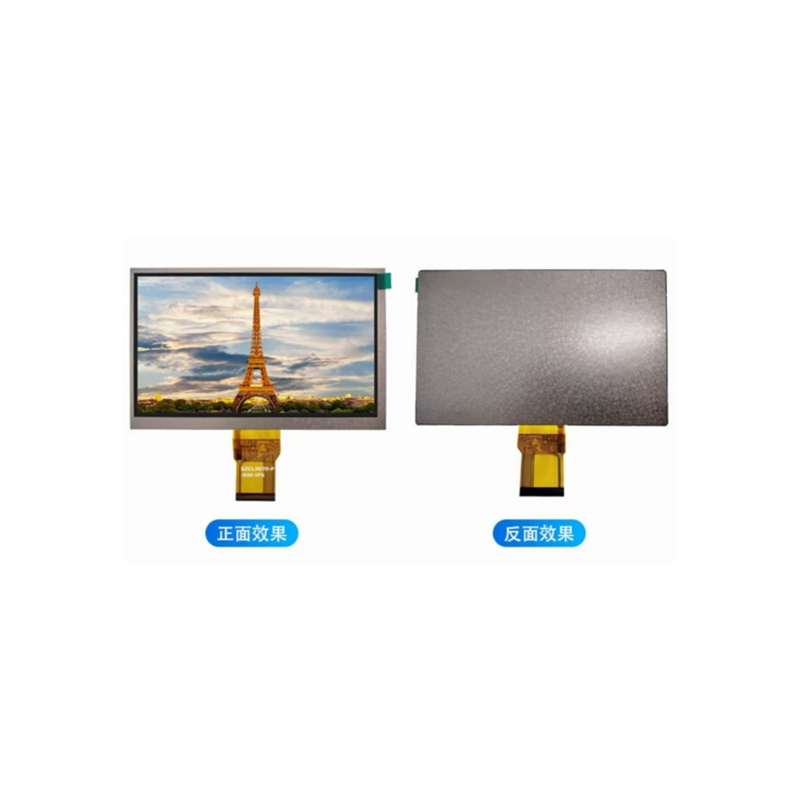

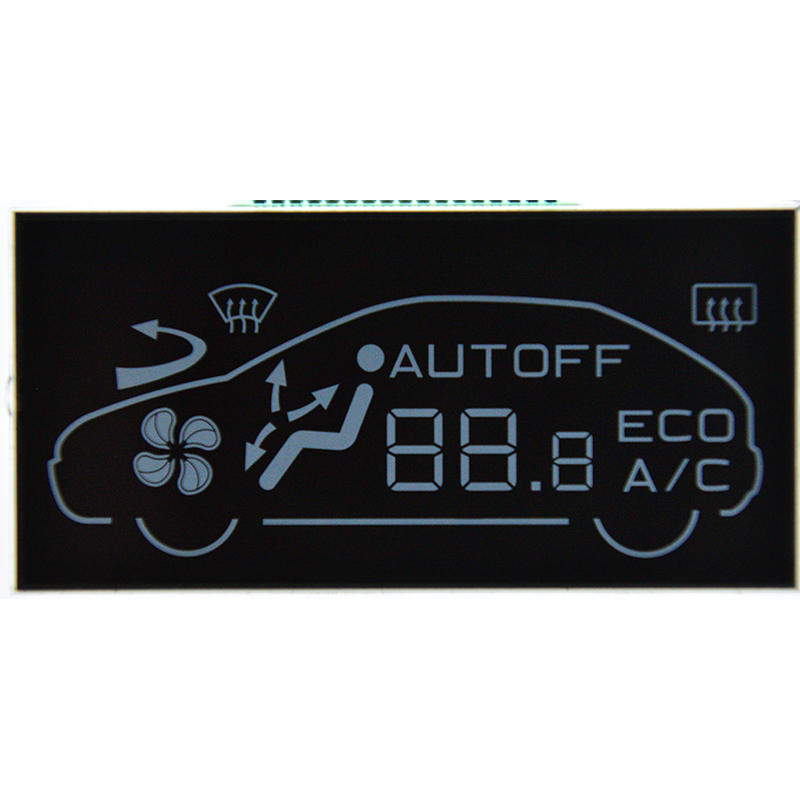

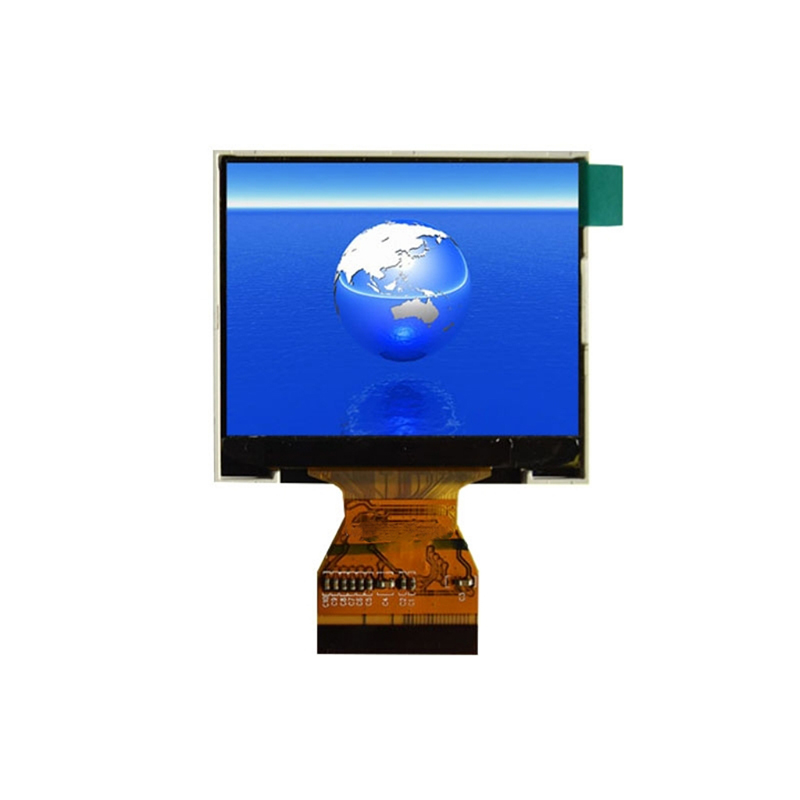

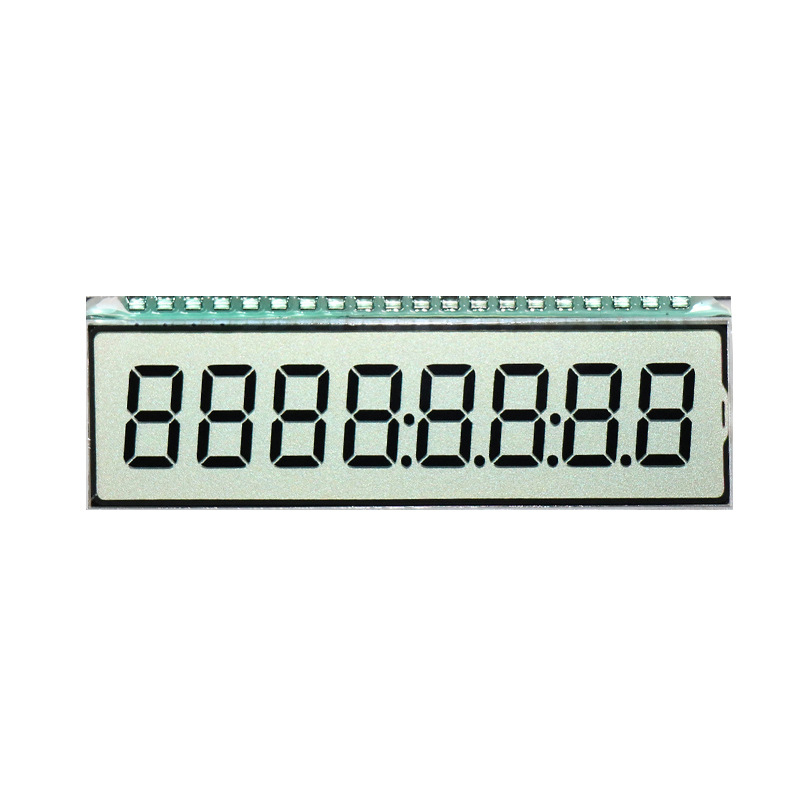

In-cell TFT displays integrate the touch sensor directly into the LCD panel, resulting in a thinner, lighter, and more responsive display. This technology offers advantages over traditional displays with separate touch layers, leading to improved image quality and durability. The benefits are numerous, including a slimmer profile, improved touch sensitivity, and a more robust and durable design. Understanding these aspects is crucial when selecting a manufacturer for your project.

Several key specifications determine the performance and suitability of an in-cell TFT display. These include resolution (measured in pixels), screen size (diagonal measurement), contrast ratio, response time, brightness, and viewing angle. It’s vital to match these specifications precisely to your project requirements. Careful consideration of these aspects is essential during the selection process of a Best in-cell TFT display factory.

Selecting a reliable in-cell TFT display factory requires careful evaluation of several factors. These include the factory's manufacturing capabilities, quality control processes, certifications (e.g., ISO 9001), experience, and customer support. A thorough due diligence process can mitigate risks and ensure a successful partnership. A factory's reputation and track record are crucial considerations.

Production capacity and lead times are critical factors to consider, especially for large-scale projects. A factory’s ability to meet your production volume and delivery deadlines is crucial for successful product launches. Understanding their production capabilities ensures seamless project execution.

Rigorous quality control measures are essential for ensuring consistent product quality. Look for factories with established quality control processes and relevant certifications, demonstrating their commitment to delivering high-quality in-cell TFT displays. These certifications provide reassurance of the factory's adherence to industry standards.

Several reputable manufacturers specialize in in-cell TFT displays. Direct comparison of various factories is recommended, examining key factors such as pricing, lead times, and minimum order quantities (MOQs). This allows you to make an informed decision based on your specific needs and budget. Consider factors such as technical support and after-sales service as well.

| Factory | Lead Time (Weeks) | MOQ | Certifications |

|---|---|---|---|

| Factory A | 6-8 | 1000 | ISO 9001, ISO 14001 |

| Factory B | 4-6 | 500 | ISO 9001 |

| Factory C | 8-10 | 2000 | ISO 9001, IATF 16949 |

Note: This table provides a hypothetical example. Actual lead times and MOQs vary depending on the specific in-cell TFT display and factory.

Ultimately, the best in-cell TFT display factory for your project depends on your specific requirements and priorities. Consider your budget, desired specifications, production volume, and delivery deadlines when making your decision. Thorough research and due diligence are key to finding the ideal partner for your needs. For high-quality displays and reliable manufacturing, consider exploring options like Dalian Eastern Display Co., Ltd.—a leading provider in the industry.