This guide provides a comprehensive overview of creating efficient and reliable Best LabVIEW SPI interface solutions. We'll explore various methods, best practices, and troubleshooting techniques to help you seamlessly integrate SPI devices into your LabVIEW applications. Learn how to optimize data transfer, handle errors, and build robust systems for your specific needs.

The Serial Peripheral Interface (SPI) bus is a synchronous, full-duplex communication protocol widely used for connecting microcontrollers and peripherals. Understanding its fundamental principles is crucial for effective LabVIEW SPI interface development. Key aspects include:

The SCLK line synchronizes data transfer between the master (typically your LabVIEW system) and the slave (the SPI device). Proper clock configuration is essential for reliable communication.

The MOSI line transmits data from the master to the slave. This is how your LabVIEW application sends commands and data.

The MISO line transmits data from the slave back to the master. This is how you receive data from your connected SPI device.

The CS line selects which slave device is currently communicating with the master. By controlling the CS line, you can manage multiple SPI devices on the same bus.

Several methods exist for creating a LabVIEW SPI interface. The optimal approach depends on factors like your hardware, the complexity of your application, and your familiarity with LabVIEW.

LabVIEW's VISA (Virtual Instrument Software Architecture) provides a powerful and versatile way to interact with instruments and devices, including those using SPI. This approach requires some familiarity with VISA resource names and settings. You’ll configure the VISA resource to represent your SPI interface and then send and receive data accordingly.

Several third-party libraries offer pre-built functions and VIs to simplify LabVIEW SPI interface development. These libraries often provide enhanced functionality, error handling, and ease of use. Research options carefully to find a library that meets your project requirements and integrates well with your current LabVIEW setup.

For advanced applications or specific hardware configurations, direct interaction with hardware registers using LabVIEW’s low-level functions may be necessary. This approach demands a deeper understanding of the SPI protocol and hardware specifications. This method provides maximum control but requires significant expertise.

To build reliable and efficient LabVIEW SPI interface solutions, consider these best practices:

Implement robust error handling mechanisms to catch and address potential issues like communication errors, timing problems, and invalid data. This can improve system stability and make debugging easier.

Always validate the received data to ensure its accuracy and integrity. Implement checks to identify corrupted or unexpected data.

SPI communication is timing-sensitive. Pay close attention to clock speeds and timing constraints to ensure reliable data transfer.

Here are some common problems encountered when developing a LabVIEW SPI interface and how to address them:

| Problem | Possible Causes | Solutions |

|---|---|---|

| No communication | Incorrect wiring, clock configuration, or CS line control | Double-check wiring, verify clock speed and polarity, and ensure proper CS line management |

| Data corruption | Timing issues, noise interference, or incorrect data format | Improve shielding, adjust clock speed, and verify data format compatibility |

| Slow data transfer | Low clock speed or inefficient code | Increase clock speed (within limits), and optimize LabVIEW code for efficient data handling |

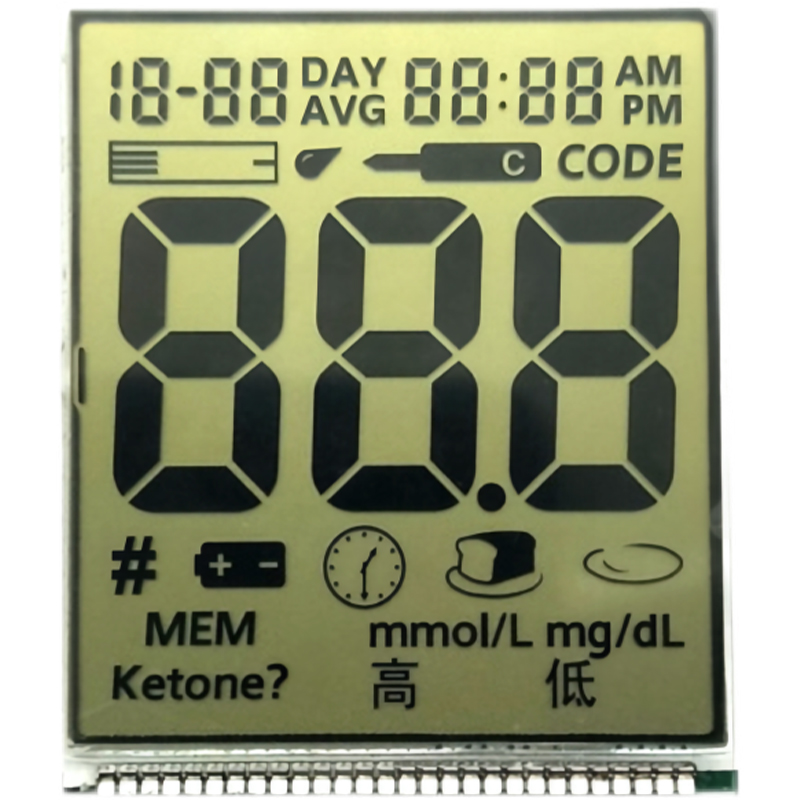

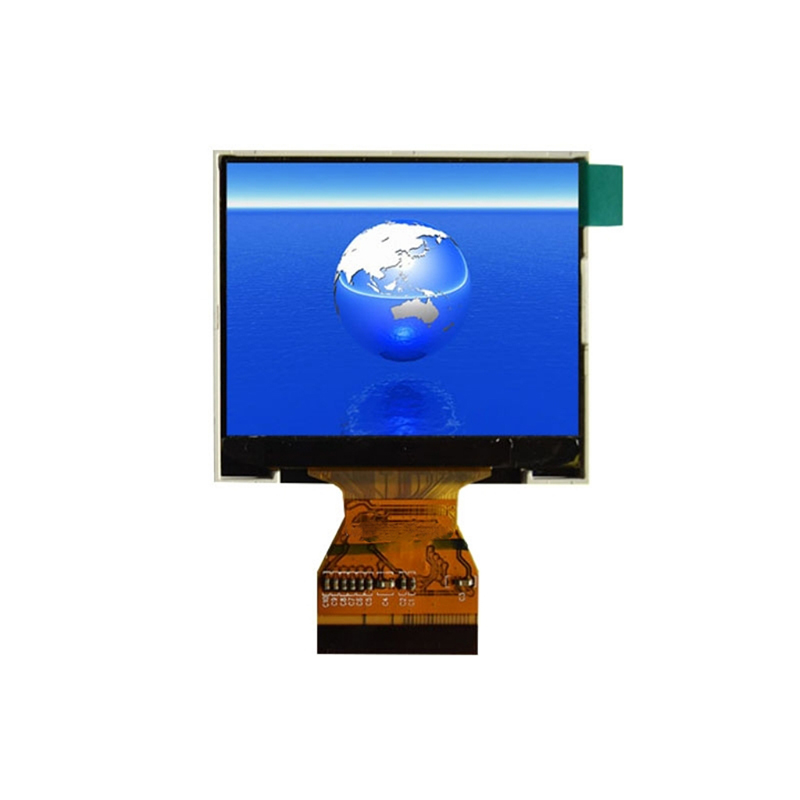

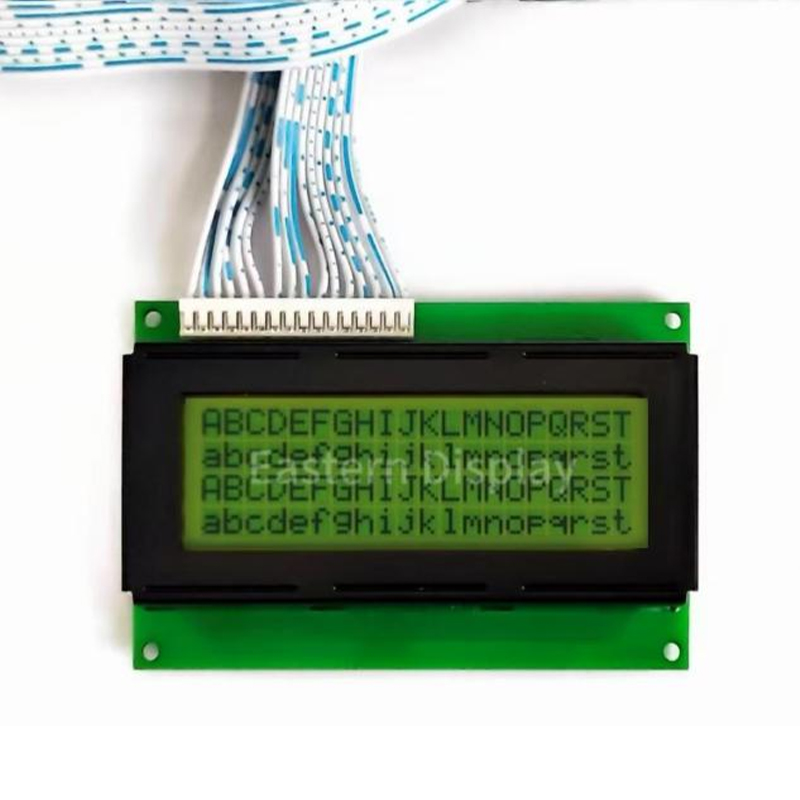

For advanced displays and integration solutions, consider exploring the possibilities with Dalian Eastern Display Co., Ltd., a leading provider of LCD modules and display technologies. Their expertise can significantly enhance your projects.

Remember, effective LabVIEW SPI interface design requires careful planning, thorough testing, and a solid understanding of both LabVIEW and SPI communication protocols. By following the guidelines and best practices outlined in this guide, you can successfully integrate SPI devices into your LabVIEW applications and create robust and reliable systems.