Developing a robust and efficient Serial Peripheral Interface (SPI) interface in LabVIEW is crucial for many applications. This guide provides a comprehensive overview of strategies, tools, and best practices to help you build high-performing Best LabVIEW SPI Interface solutions. We will explore various aspects, including hardware considerations, software implementation techniques, and troubleshooting tips, ensuring you can effectively integrate SPI devices into your LabVIEW projects. This guide is designed for developers of varying skill levels, providing valuable insights for both beginners and experienced LabVIEW programmers.

SPI (Serial Peripheral Interface) is a synchronous, full-duplex communication protocol used for connecting microcontrollers and other peripherals. It features four key lines: MOSI (Master Out Slave In), MISO (Master In Slave Out), SCLK (Serial Clock), and SS (Slave Select). Understanding the timing diagrams and data transfer mechanisms is essential for successful implementation in LabVIEW.

LabVIEW, with its graphical programming environment, offers powerful tools for interfacing with hardware. Its built-in functions and libraries simplify the development process, allowing for easy configuration and control of SPI communication parameters. The use of VISA (Virtual Instrument Software Architecture) is often employed for low-level communication with SPI devices.

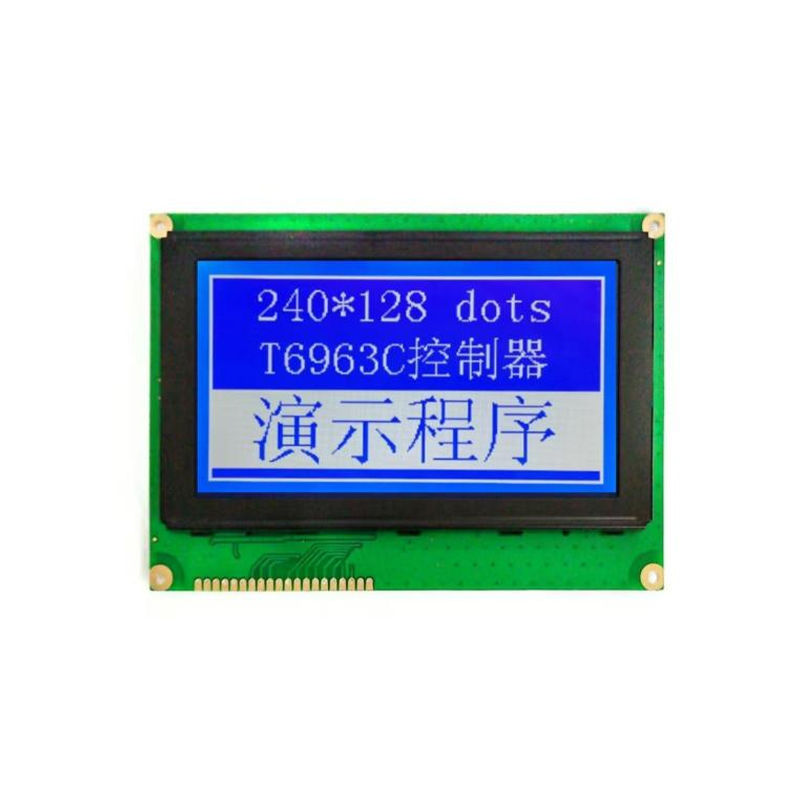

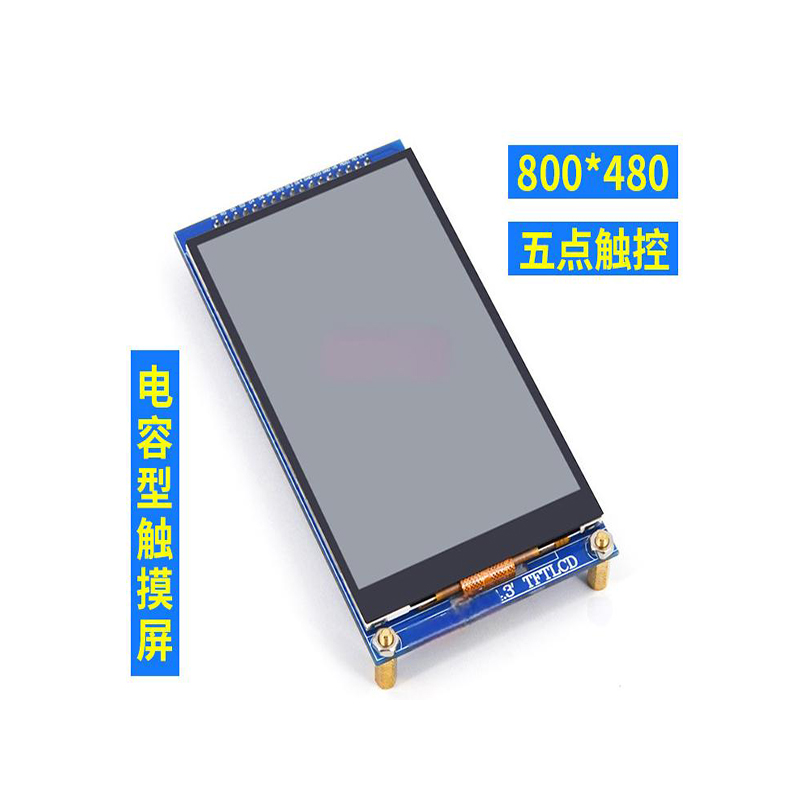

The success of your Best LabVIEW SPI Interface depends heavily on the choice of SPI devices. Factors to consider include data rate, communication protocols supported, power consumption, and physical interface compatibility. Detailed datasheets should be consulted to verify compatibility and understand operational specifications.

Using the appropriate data acquisition (DAQ) devices or other hardware interfaces is crucial for connecting your SPI devices to your computer. Consider the number of channels required, the sampling rate needed, and the overall system architecture when making your selection. Many NI data acquisition devices readily support SPI communication through their LabVIEW drivers.

This section will walk through the steps of creating a LabVIEW Virtual Instrument (VI) for controlling an SPI device. We'll cover setting up VISA resources, configuring the SPI communication parameters (clock speed, data bits, etc.), and writing code for data transmission and reception. Examples using common LabVIEW functions such as VISA Write and VISA Read will be provided.

Robust error handling is crucial for reliable operation. The VI should include checks for communication errors, data integrity issues, and unexpected events. Data validation techniques, such as checksum verification, help ensure the accuracy of transmitted and received data. Proper error handling ensures the stability and reliability of your Best LabVIEW SPI Interface.

Optimizing SPI communication for speed and efficiency is vital for high-throughput applications. Techniques such as using DMA (Direct Memory Access) and carefully managing buffer sizes can significantly improve performance. This section will delve into strategies for optimizing communication speed in LabVIEW.

LabVIEW's advanced features, such as state machines and parallel programming, can be leveraged to create more complex and efficient SPI control systems. This section explores the use of these features for building sophisticated SPI interfaces.

This section covers some frequently encountered problems when building Best LabVIEW SPI Interface and provides solutions. Troubleshooting steps are presented in a clear and concise manner, making it easier for developers to resolve common issues during development and deployment.

This section lists helpful resources for further learning and exploration of LabVIEW SPI interface development, including links to relevant documentation, tutorials, and online communities. Links will be provided to relevant National Instruments documentation and other helpful resources.

| Feature | Option A | Option B |

|---|---|---|

| Data Rate | 10 Mbps | 20 Mbps |

| Power Consumption | 50 mW | 100 mW |

| Cost | $10 | $20 |

Note: Specific data and pricing will vary depending on the chosen hardware components and vendor. Please refer to relevant datasheets for accurate information.

For more information on high-quality LCD displays, visit Dalian Eastern Display Co., Ltd.