This guide helps you navigate the landscape of best lcd display tester factory options, providing insights into critical factors to consider when selecting a supplier. We'll explore various testing methods, crucial features to look for in testers, and considerations for successful partnerships.

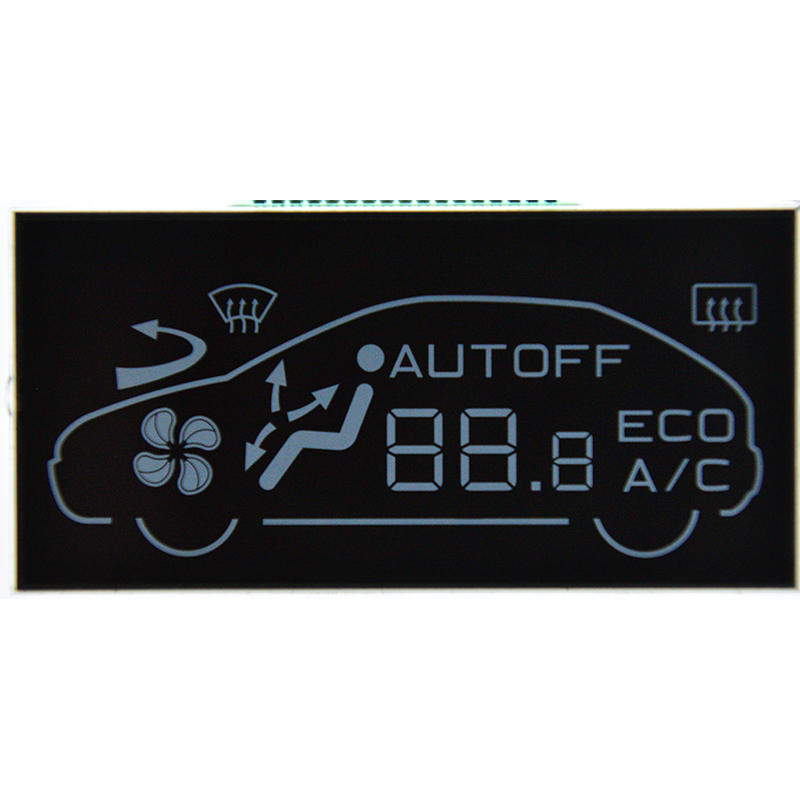

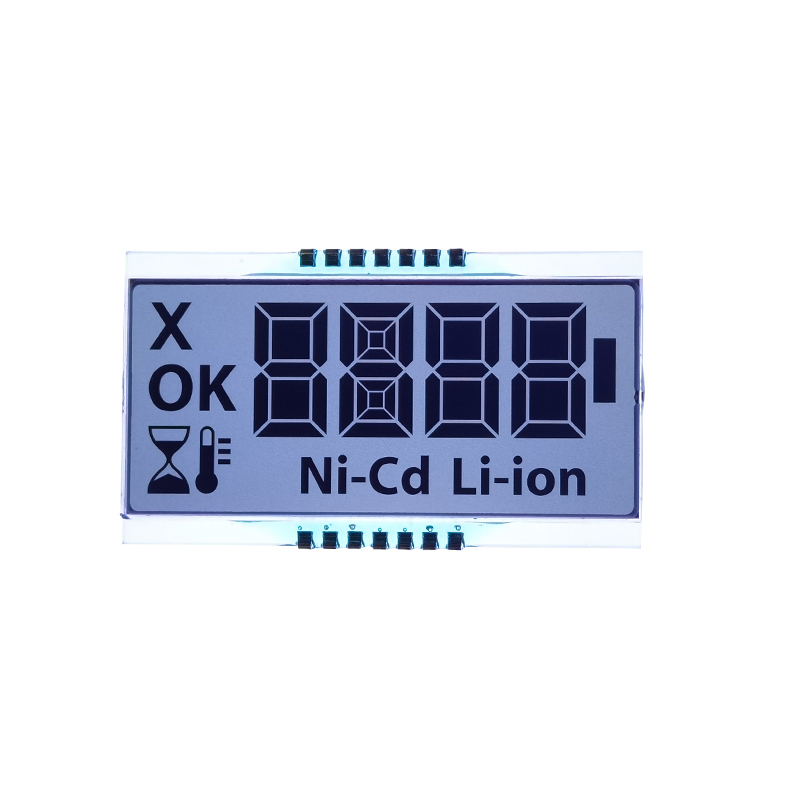

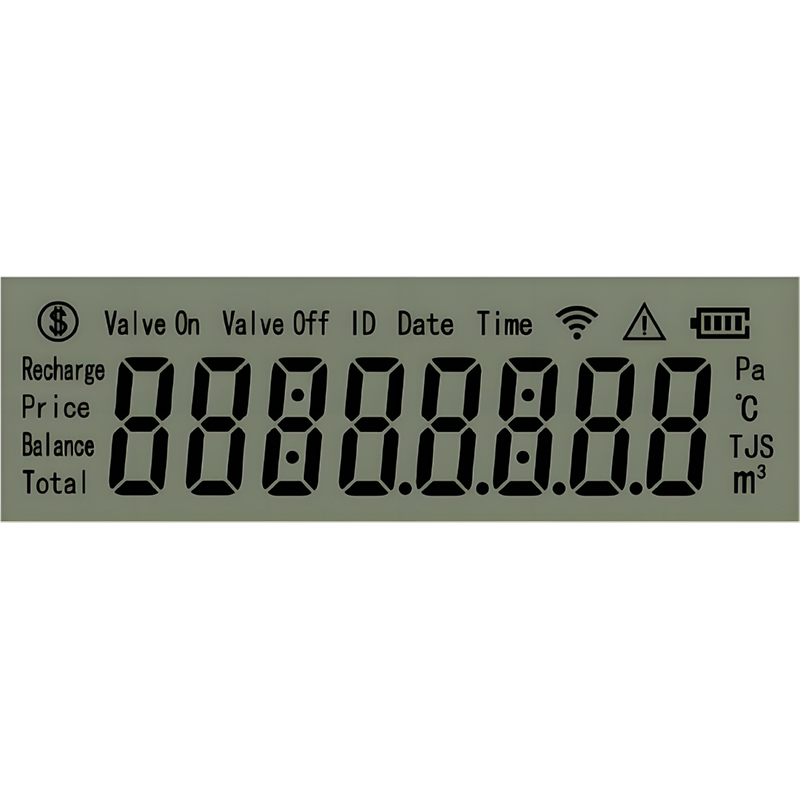

The market offers a variety of lcd display tester factory solutions, each catering to different needs. Common types include automated testers for high-volume production, benchtop testers for smaller-scale operations, and specialized testers for specific LCD technologies (like OLED or mini-LED).

When evaluating best lcd display tester factory options, prioritize testers with accurate colorimetry, high-resolution image display capabilities, and comprehensive diagnostic features. Look for advanced features like backlight testing and touch screen functionality testing, depending on your specific display requirements. Consider compatibility with your existing production lines and software infrastructure. The testing speed and throughput capacity should also be carefully assessed based on your production volume.

Thoroughly vet potential best lcd display tester factory candidates. Investigate their experience, manufacturing capabilities, quality control processes, and customer support services. Review testimonials and case studies to gauge their reputation and reliability. A strong track record of on-time delivery and responsiveness to customer needs is crucial. Consider the factory's geographical location and its impact on logistics and lead times.

Balance the initial investment cost of the testers with long-term operational expenses, including maintenance, repair, and calibration costs. Factor in the total cost of ownership (TCO) when comparing different options from various best lcd display tester factory providers. This will provide a clearer picture of the true expense associated with each choice.

Ensure the best lcd display tester factory you select adheres to strict quality control standards and holds relevant industry certifications (e.g., ISO 9001). These certifications demonstrate a commitment to delivering high-quality products and reliable services. Regular calibration and maintenance procedures are also key indicators of a quality-focused manufacturer.

Effective communication is paramount. Choose a best lcd display tester factory known for transparent and proactive communication. A collaborative partnership ensures that any issues or challenges are addressed promptly and effectively. Regular communication channels are crucial for project updates, issue resolution and mutual understanding.

Some best lcd display tester factory offer customization options to tailor their testers to your specific requirements. This can include integrating specific test procedures or adapting the user interface to your workflow. The level of customization offered can be a key differentiator when choosing a supplier. Flexibility in terms of order size and delivery schedules is also beneficial.

| Feature | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Testing Speed | 100 units/hour | 150 units/hour | 80 units/hour |

| Resolution | 4K | 2K | 4K |

| Customization | Limited | Extensive | Moderate |

Remember to conduct your own thorough research and due diligence before selecting a best lcd display tester factory. Consider factors like your specific testing needs, budget, and long-term goals when making your decision. For high-quality LCD display testing solutions, consider exploring the capabilities of Dalian Eastern Display Co., Ltd. a leading manufacturer in the industry. Their expertise and commitment to quality can help ensure the success of your project.