This guide explores the world of best LCD glass, examining factors to consider when choosing the right glass for your needs. We'll delve into different types, quality considerations, and applications, helping you make an informed decision. Whether you're a manufacturer, repair technician, or simply curious about the technology, this resource provides valuable insights.

LCD glass comes in various forms, each with its own characteristics. The most common include soda-lime glass, aluminosilicate glass, and borosilicate glass. Soda-lime glass is the most common and cost-effective option, while aluminosilicate and borosilicate glasses offer enhanced strength and durability, making them suitable for demanding applications. The choice of glass significantly impacts the overall performance and longevity of the LCD screen. Consider factors such as scratch resistance, impact resistance, and optical clarity when making your selection.

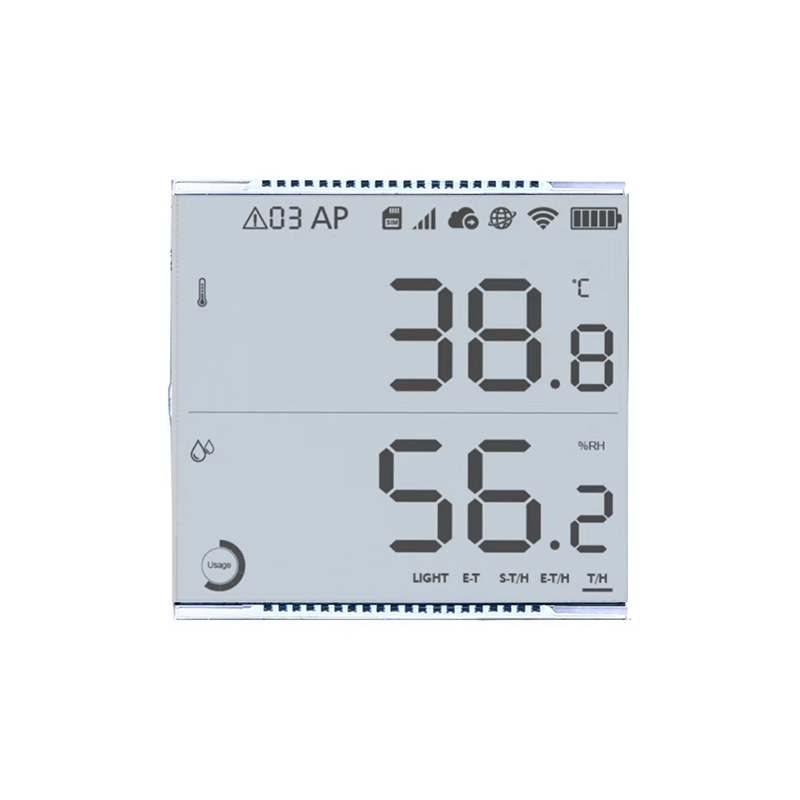

Beyond the type of glass, the quality of the manufacturing process is crucial. Look for glass that meets industry standards for optical clarity, surface smoothness, and dimensional accuracy. Defects such as bubbles, scratches, or inconsistencies in thickness can compromise the image quality and performance of the LCD screen. Reputable manufacturers like Dalian Eastern Display Co., Ltd. prioritize rigorous quality control measures throughout their production process, ensuring consistently high-quality LCD glass.

Selecting the appropriate best LCD glass depends on the specific application. Key factors include:

LCD glass finds applications in a wide range of devices and industries, including:

Several manufacturers offer high-quality LCD glass. Careful comparison is essential to determine the best option for your specific requirements. Consider factors like:

A thorough evaluation will help you choose a reliable supplier providing the best LCD glass for your needs. Always check for independent reviews and testimonials to gain a better understanding of a manufacturer's reputation and product quality.

While both are crucial components of LCD screens, they are distinct. LCD glass forms the substrate for the liquid crystal display itself. Touch screen glass is a separate layer added on top, enabling touch input functionality.

Use a microfiber cloth slightly dampened with distilled water or a dedicated LCD screen cleaner. Avoid harsh chemicals or abrasive materials that could scratch the LCD glass surface.

| Feature | Soda-Lime Glass | Aluminosilicate Glass | Borosilicate Glass |

|---|---|---|---|

| Cost | Low | Medium | High |

| Durability | Moderate | High | Very High |

| Chemical Resistance | Moderate | High | Very High |

Remember to always consult with a specialist or manufacturer for specific advice based on your individual application needs. Choosing the right best LCD glass is key to ensuring optimal performance and longevity.