Finding the right Best LCD Manufacturer factory for your needs can be challenging. This guide provides a comprehensive overview of key factors to consider, helping you make an informed decision. We'll explore different types of LCDs, manufacturing processes, crucial considerations for choosing a manufacturer, and even offer insights into ensuring quality control. Learn how to select a partner that aligns with your project requirements and budget.

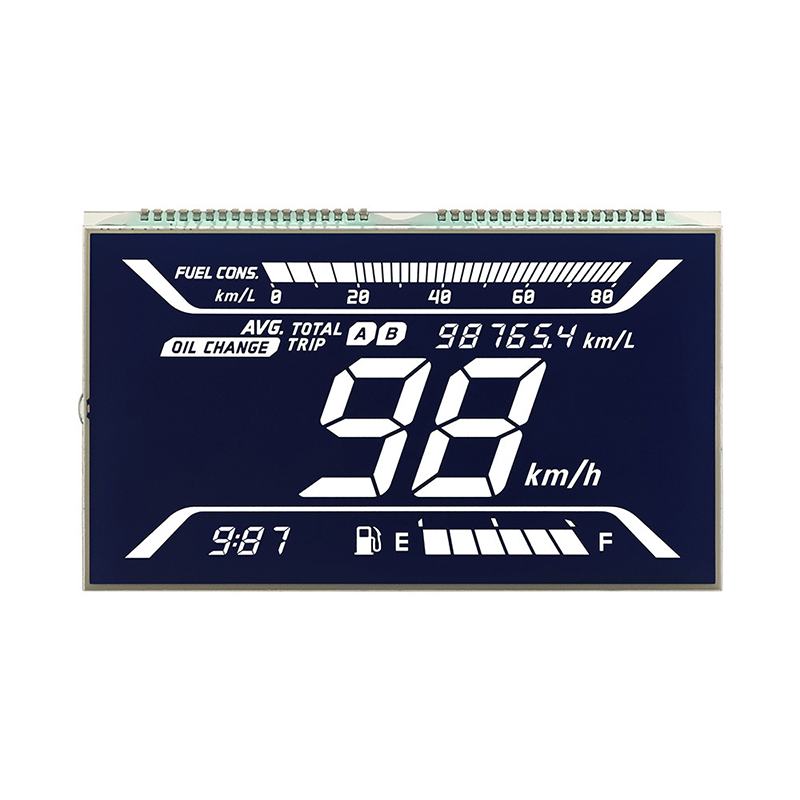

The market offers various types of LCDs, each with its own strengths and weaknesses. Understanding these differences is crucial for selecting the right Best LCD Manufacturer factory. Common types include TN, IPS, VA, and OLED. TN panels are known for their fast response times but often suffer from poor viewing angles. IPS panels provide excellent color accuracy and viewing angles, but response times might be slower. VA panels balance the two, offering good contrast and viewing angles with relatively fast response times. OLEDs, while not strictly LCDs, are often grouped with them due to their display technology and frequently mentioned when searching for 'Best LCD Manufacturer factory'. The choice depends on the specific application; for example, a gaming monitor might prioritize a TN or IPS panel with a fast refresh rate, while a professional photo editing monitor would benefit from an IPS panel's color accuracy.

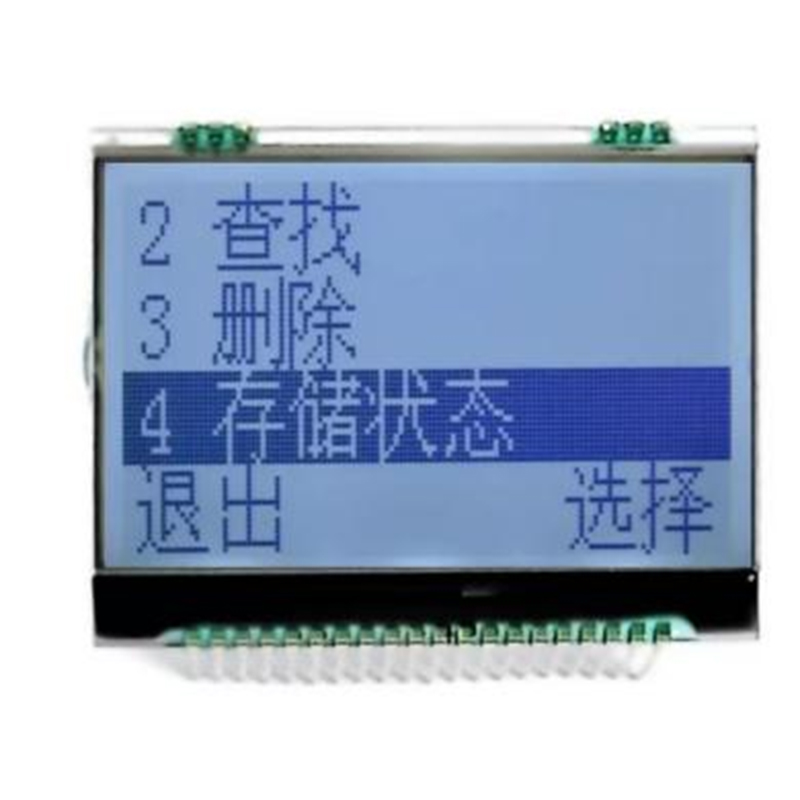

The manufacturing process is complex and involves multiple stages, from substrate preparation to module assembly. Understanding this process allows you to better appreciate the intricacies of LCD production and choose a manufacturer with the necessary expertise. Key steps include: substrate cleaning, thin-film transistor (TFT) backplane formation, color filter integration, liquid crystal injection, and module assembly. High-quality Best LCD Manufacturer factorys maintain stringent quality control at each stage to ensure consistent and reliable products.

Selecting the right manufacturer is critical. Consider factors such as:

Thoroughly investigate potential Best LCD Manufacturer factory partners. Request samples, conduct site visits (if feasible), and review their quality certifications. References and testimonials from other clients can also provide valuable insights. Don't hesitate to ask detailed questions about their manufacturing processes, quality control measures, and capacity.

Implementing a robust quality control system is paramount for any successful LCD production. This involves regular inspections throughout the manufacturing process and testing procedures to ensure that each unit meets predefined specifications. Look for manufacturers with ISO certifications, or other industry-recognized quality standards. Dalian Eastern Display Co., Ltd., for example, is a reputable manufacturer with a strong focus on quality.

Finding the Best LCD Manufacturer factory requires careful consideration of various factors. By understanding LCD technology, the manufacturing process, and conducting thorough due diligence, you can choose a reliable partner capable of meeting your needs and delivering high-quality products. Remember to prioritize quality control, capacity, and communication throughout your selection process.

| Feature | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Production Capacity (Units/Month) | 100,000 | 50,000 | 75,000 |

| Lead Time (Weeks) | 6 | 8 | 7 |

| Price per Unit ($) | 15 | 18 | 16 |

Note: Manufacturer data is hypothetical for illustrative purposes.