This guide helps you identify top-tier Best lcd monitor tester factory for your needs, considering factors like testing capabilities, production capacity, quality control, and global reach. We'll explore key aspects to assist your decision-making process.

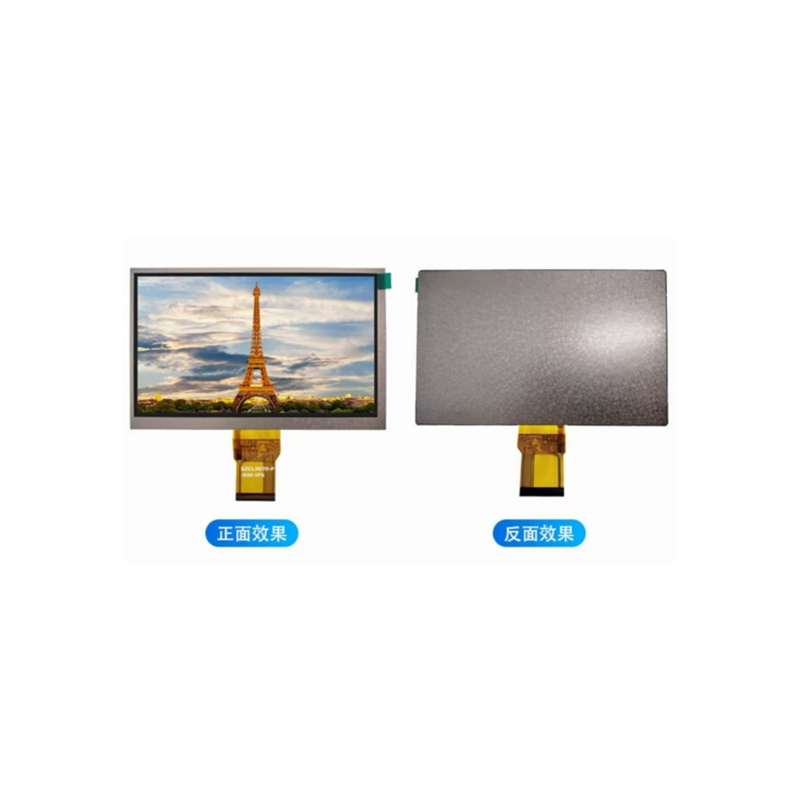

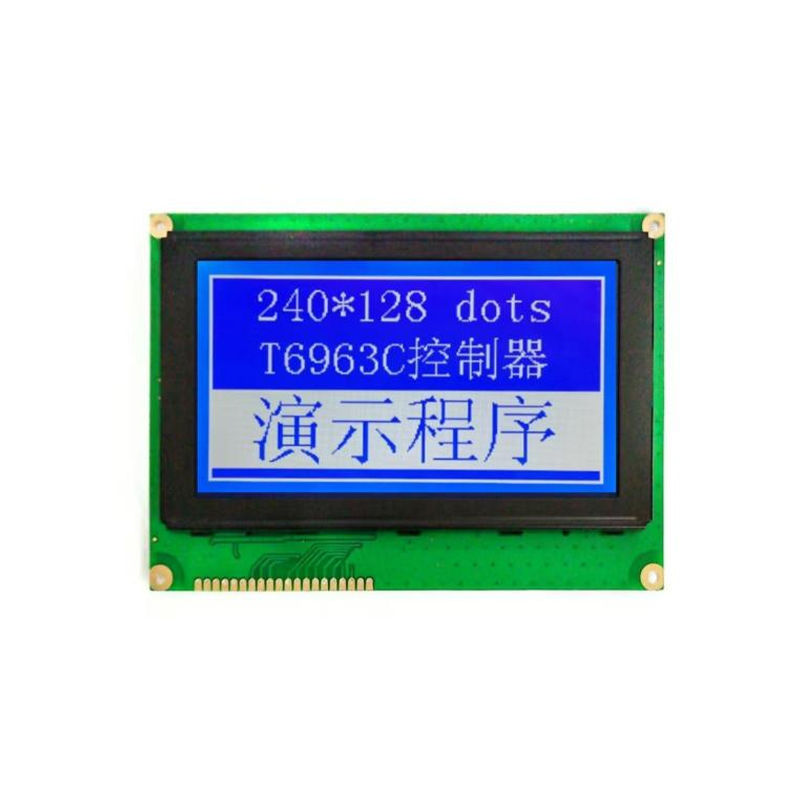

Before searching for a Best lcd monitor tester factory, clearly define your testing needs. Consider the types of LCD monitors you produce (size, resolution, panel type, etc.), the specific tests required (backlight uniformity, color accuracy, pixel defects, response time), and the desired testing speed and automation level. Understanding these aspects helps you choose a factory aligned with your specifications.

Several tests are critical for ensuring LCD monitor quality. These include:

Assess the factory's production capacity to meet your current and future needs. A scalable factory can adapt to increasing demand without compromising quality or delivery times. Consider their experience with various LCD monitor types and sizes.

Rigorous quality control is paramount. Look for factories with well-established processes, including multiple testing stages, statistical process control (SPC), and experienced quality inspectors. Inquire about their defect rates and customer satisfaction metrics.

Advanced testing technologies and automation significantly improve efficiency and accuracy. Explore factories employing automated testing systems and utilizing advanced image processing techniques for precise defect detection.

Depending on your location and distribution network, the factory's global reach and logistics capabilities are crucial. Consider factors like shipping costs, lead times, and customs clearance procedures. A factory with a proven track record of international shipments is advantageous.

Conduct thorough due diligence, including verifying certifications and licenses. On-site visits allow you to assess the factory's facilities, equipment, and workforce firsthand. This provides valuable insights into their operational processes and quality standards.

Effective communication and collaboration are vital throughout the partnership. Choose a factory with responsive and professional customer service. Clear communication channels prevent misunderstandings and streamline the entire testing process.

| Factor | Importance |

|---|---|

| Testing Capabilities | High - Ensures comprehensive quality checks |

| Production Capacity | High - Meets current and future demands |

| Quality Control | High - Guarantees consistent product quality |

| Global Reach | Medium - Depends on your distribution network |

| Cost-Effectiveness | High - Balancing quality with budget |

For a leading example of a reputable Best lcd monitor tester factory, consider exploring Dalian Eastern Display Co., Ltd.. They offer comprehensive testing solutions and advanced manufacturing capabilities. Remember to thoroughly research and compare various factories before making your final decision.