This guide helps you navigate the world of LCD screen manufacturing, providing insights into choosing the ideal best LCD screen factory for your needs. We'll explore key factors to consider, helping you make an informed decision. Discover crucial aspects like production capabilities, quality control measures, and ethical considerations, ensuring you find a reliable partner for your LCD screen requirements.

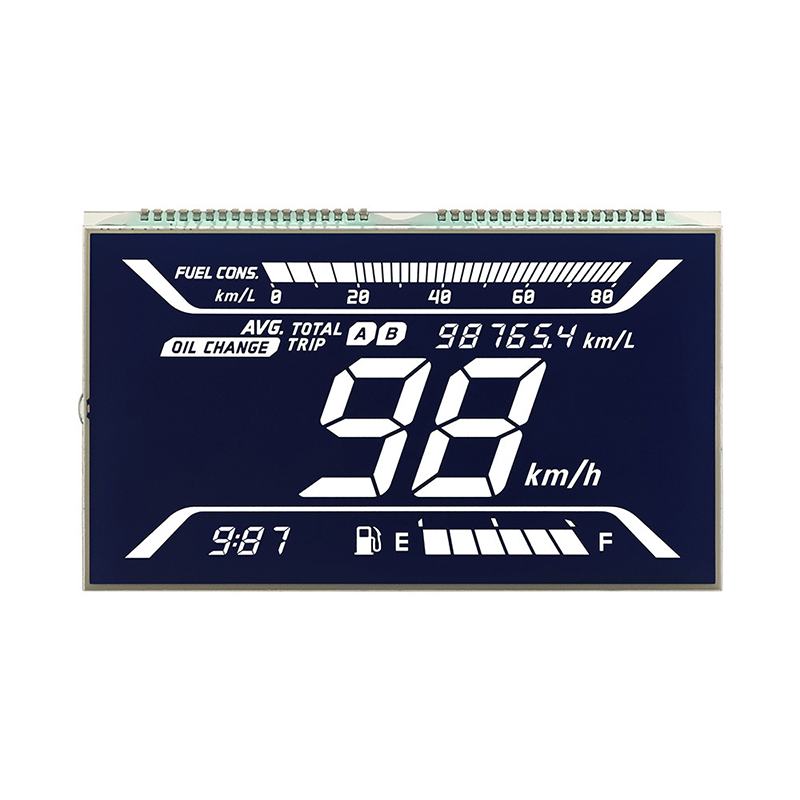

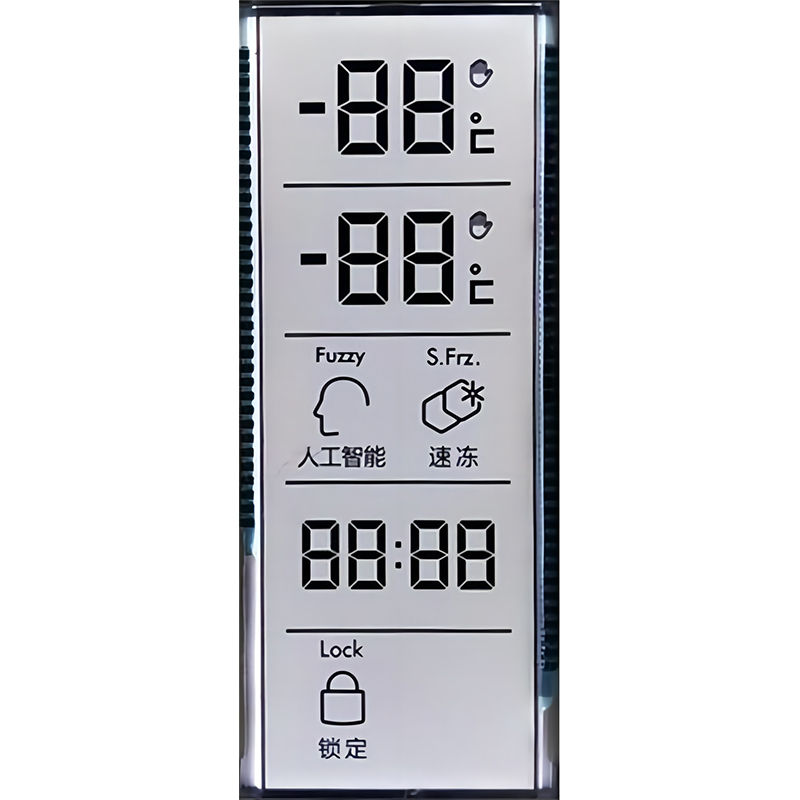

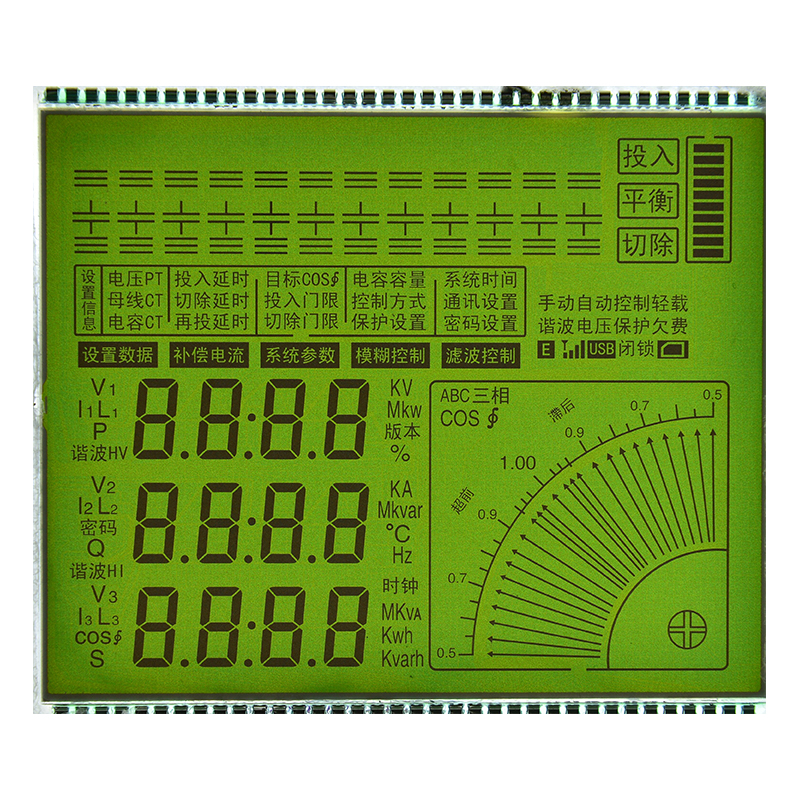

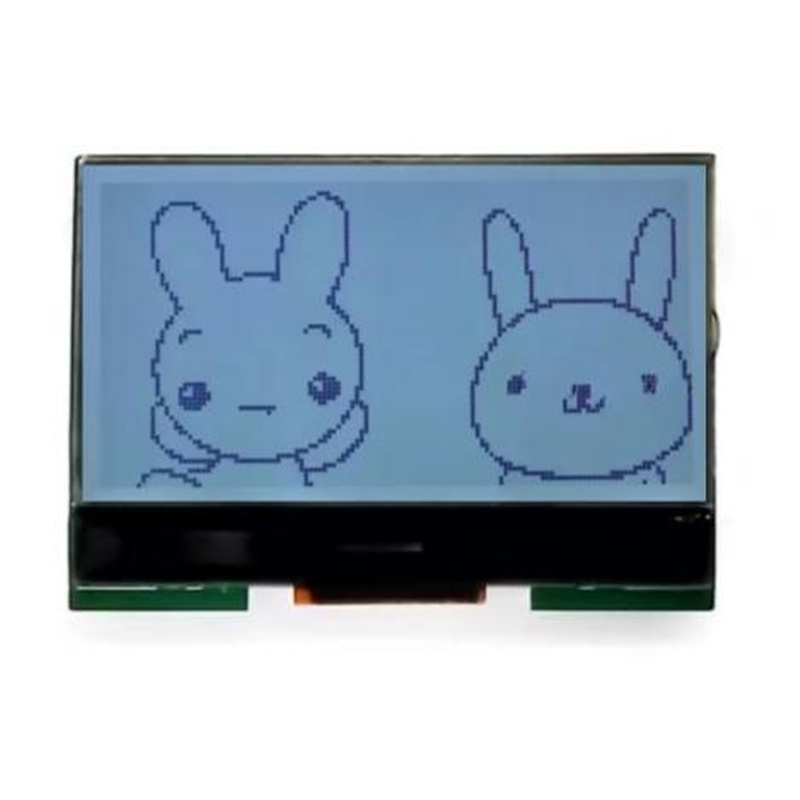

Before embarking on your search for the best LCD screen factory, clearly define your requirements. Consider factors such as screen size, resolution, response time, brightness, contrast ratio, and viewing angle. Understanding your specific needs will help you narrow down your options and focus your efforts on manufacturers specializing in your desired specifications. Are you looking for high-resolution screens for professional applications, or more cost-effective solutions for consumer electronics? This initial step is crucial for a successful partnership.

Your production volume will significantly impact your choice of best LCD screen factory. Smaller manufacturers might excel in customization and quick turnaround times, while larger factories are better suited for mass production. Equally important is your project timeline. Communicate your deadlines clearly to prospective manufacturers to ensure they can meet your production schedule.

Investigate the potential manufacturer's production capacity, technological capabilities, and experience. Look for companies with a proven track record and a demonstrated ability to consistently deliver high-quality products. Many reputable factories offer detailed specifications and certifications on their websites. Check for certifications such as ISO 9001, which demonstrates a commitment to quality management systems.

A reliable best LCD screen factory will have robust quality control procedures in place. Inquire about their testing processes, including defect rates and failure analysis methods. Request samples and thoroughly inspect them to assess the quality of their workmanship. Companies committed to quality often openly share their testing methods and results.

In today's increasingly conscious market, ethical sourcing and sustainable practices are critical. Investigate the manufacturer's environmental policies and labor practices. Look for certifications like Fair Trade or similar, demonstrating a commitment to responsible manufacturing.

Once you've identified a few potential candidates, create a comparison table to evaluate them objectively. Consider factors like pricing, lead times, minimum order quantities, and communication responsiveness. This methodical approach allows for a fair and efficient comparison, leading to a more informed decision.

| Factory | Production Capacity | Lead Time | Pricing | Certifications |

|---|---|---|---|---|

| Factory A | High | 4-6 weeks | Competitive | ISO 9001 |

| Factory B | Medium | 2-4 weeks | Higher | ISO 9001, ISO 14001 |

| Dalian Eastern Display Co., Ltd. (https://www.ed-lcd.com/) | Customizable | Project Specific | Competitive | [Insert Certifications Here] |

Selecting the best LCD screen factory requires careful consideration of multiple factors. By thoroughly evaluating potential manufacturers and using a structured comparison process, you can confidently choose a partner that meets your quality, cost, and ethical requirements. Remember to always prioritize open communication and a collaborative approach to ensure a successful partnership.