Finding the right Best LCD screen tester is crucial for ensuring the quality of your LCD screens. However, the testing process itself requires careful management, particularly when it comes to exiting the test. This guide will equip you with the knowledge and strategies to efficiently and accurately conclude your LCD screen testing, leading to improved productivity and reduced errors. We will delve into different testing methodologies, analyze potential issues, and provide practical solutions for a smooth exit strategy from your testing process. Proper exit strategies are crucial for preventing data corruption and ensuring the reliability of your test results. This is vital whether you’re working with small-scale projects or large-scale production lines.

Different Best LCD screen tester models employ varying exit procedures. Some may require a simple button press, while others might involve software commands or specific sequences. Understanding your specific tester's documentation is paramount. Before beginning any test, familiarize yourself with the manufacturer's instructions for properly exiting the test mode. This will prevent unexpected issues and ensure data integrity.

Many basic Best LCD screen testers utilize manual exit procedures. This typically involves pressing a designated button or switch. Always ensure the tester is in a stable state before attempting to exit. Rushing this step can lead to incomplete data logging or even damage to the equipment. For instance, the common power off button should be engaged after the internal processes have been completed, as indicated by on-screen prompts or LEDs.

Advanced Best LCD screen testers often rely on software control for the exit process. This usually involves using specific commands or functions within the tester's software interface. A proper shutdown sequence within the software will ensure all processes are closed and data is saved correctly. Failure to do so may corrupt data or lead to system instability. Consult the software's manual for detailed instructions on the proper shutdown procedures.

Even with proper procedures, issues can arise. Here are some common problems and their solutions:

If the tester freezes, try a forced power-off by disconnecting the power supply. Once the power is restored, carefully check for any error messages. If the problem persists, contact the manufacturer for support. This may indicate a more serious hardware or software fault.

Ensure your tester is configured correctly for data logging. Review the settings to ensure all data points are being recorded and saved properly. If data loss occurs repeatedly, consider upgrading your software or contacting the manufacturer to rule out any hardware malfunction.

Implementing best practices can significantly improve your LCD screen testing workflow and reduce the likelihood of exit-related problems. Consider creating standardized operating procedures (SOPs) for your team to follow, ensuring consistency and minimizing errors. Regular maintenance and calibration of your Best LCD screen tester are also crucial for long-term performance and reliability.

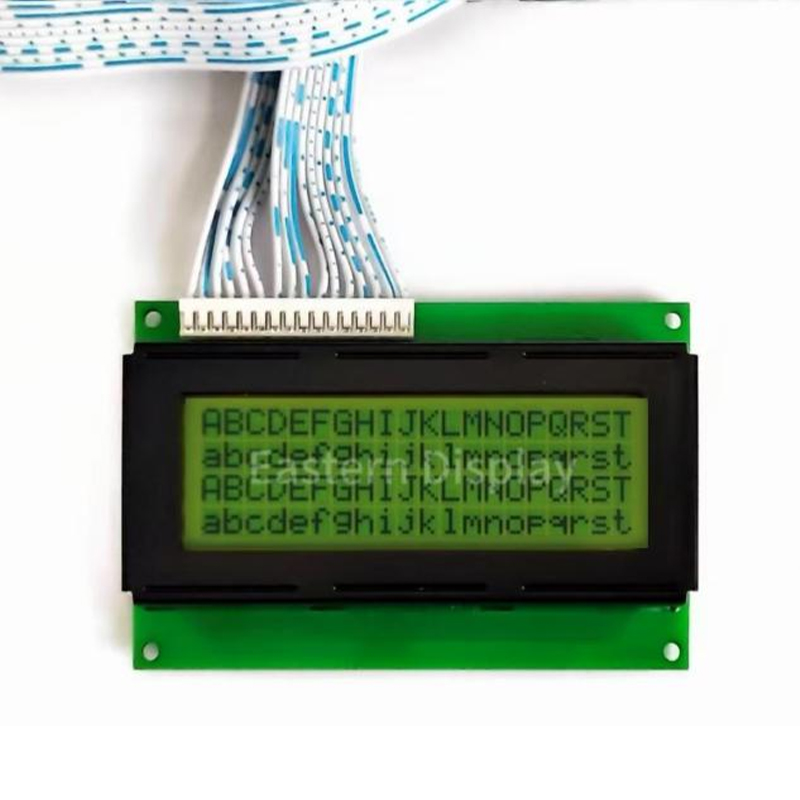

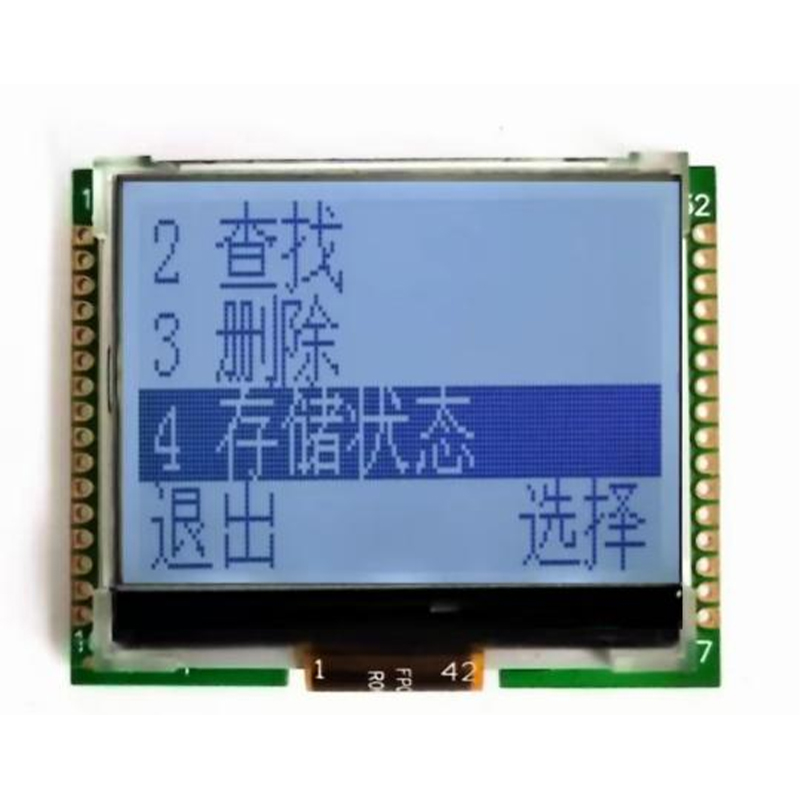

The selection of a suitable Best LCD screen tester depends on several factors, including the type of LCD screens being tested, the required accuracy, and the testing environment. Several reputable manufacturers produce high-quality LCD screen testers; research and compare different models to find the one that best meets your specific needs. For instance, if you are a large-scale manufacturer, you might require a more robust and automated system compared to a small repair shop. Dalian Eastern Display Co., Ltd. (https://www.ed-lcd.com/) is a leading provider of advanced display solutions. Their expertise in this field is invaluable for ensuring a smooth and efficient testing process.

| Feature | Tester A | Tester B |

|---|---|---|

| Accuracy | ±0.5% | ±0.2% |

| Speed | 10 screens/hour | 20 screens/hour |

| Cost | $500 | $1000 |

Remember, a well-defined exit strategy is just as important as the testing process itself. By following these guidelines and choosing the appropriate equipment, you can ensure accurate, efficient, and reliable results in your LCD screen testing.