This guide helps you navigate the landscape of online Best LCD tester online factory, offering insights into choosing the right supplier for your needs. We'll explore key factors to consider, ensuring you make an informed decision when sourcing LCD testers.

Before embarking on your search for a Best LCD tester online factory, clearly define your specific requirements. Consider the types of LCD screens you'll be testing (size, resolution, technology), the testing functionalities needed (brightness, color accuracy, pixel defects), and the volume of testing you anticipate. Understanding your needs upfront streamlines the selection process and prevents purchasing unsuitable equipment.

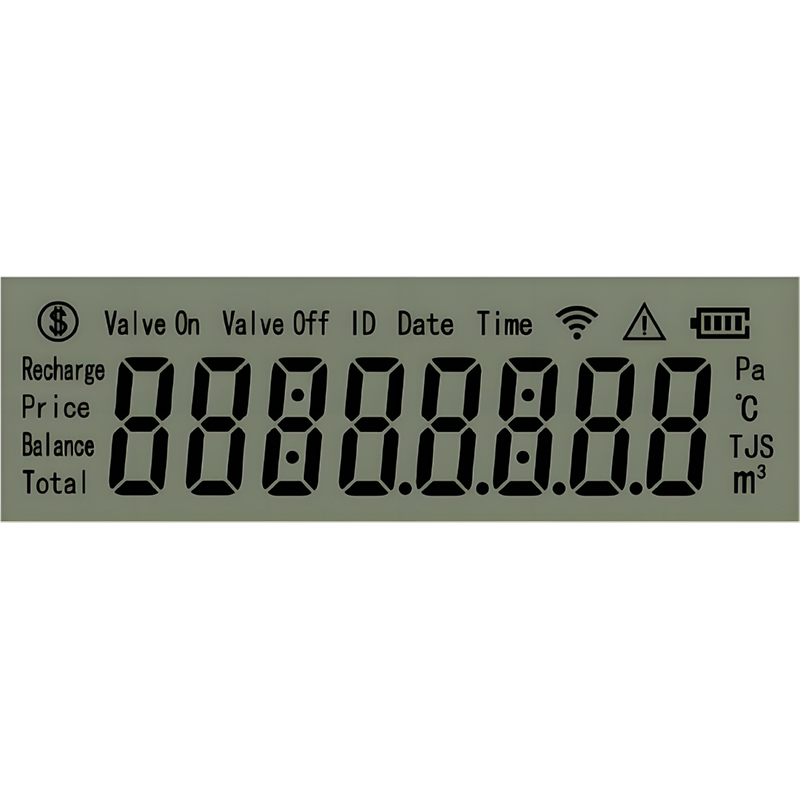

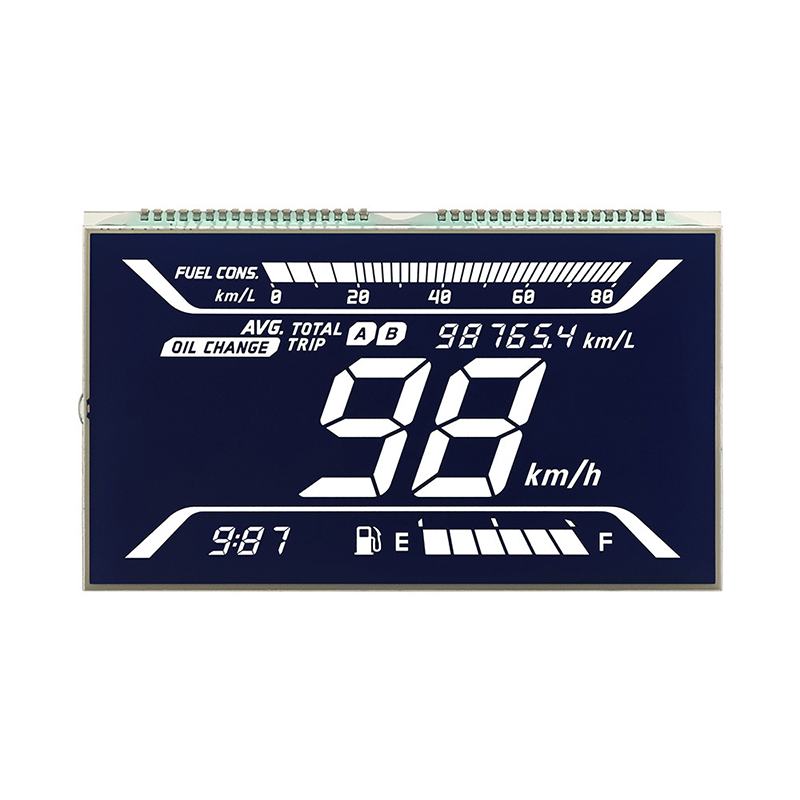

Several types of LCD testers cater to different needs. Some focus on basic functionality, while others offer advanced features for specialized testing. Research the various types available, comparing their capabilities and suitability for your specific applications. Consider factors such as automated testing capabilities, reporting features, and integration with existing workflows.

Investigate the manufacturing capabilities of potential suppliers. Look for factories with a proven track record, established quality control processes, and relevant certifications (e.g., ISO 9001). Verify their experience in producing LCD testers and assess their capacity to meet your specific order volume and timelines. Reputable suppliers will readily provide details about their facilities and production processes.

Thoroughly research the online reputation of potential suppliers. Check independent review platforms, industry forums, and online business directories. Look for consistent positive feedback regarding product quality, customer service, and on-time delivery. Negative reviews, if present, should be carefully considered to understand potential risks.

Compare pricing across different suppliers, ensuring you understand all associated costs (including shipping, taxes, and potential minimum order quantities). Negotiate favorable payment terms that align with your business needs and risk tolerance. Obtain clear quotes specifying all costs and payment schedules.

The accuracy and precision of the LCD tester are paramount. Ensure the tester meets your required accuracy levels for various parameters like color accuracy, brightness, and response time. Look for testers with calibration capabilities to maintain accuracy over time.

The user interface should be intuitive and easy to navigate, even for users with limited technical expertise. A well-designed interface streamlines the testing process and minimizes errors. Consider the availability of comprehensive documentation and user support.

Advanced LCD testers often include sophisticated software for automated testing and data analysis. Evaluate the software's features, data reporting capabilities, and compatibility with your existing systems. Robust reporting functionalities are crucial for tracking test results and identifying potential issues.

Choosing the right Best LCD tester online factory requires careful consideration of your specific needs, thorough supplier research, and a detailed evaluation of the LCD testers themselves. By following the steps outlined in this guide, you can confidently select a supplier that meets your requirements and provides high-quality LCD testers.

For a leading manufacturer of high-quality LCD displays and related equipment, consider exploring Dalian Eastern Display Co., Ltd. They offer a wide range of products and services to meet diverse industry needs.

| Feature | Supplier A | Supplier B |

|---|---|---|

| Accuracy | ±0.5% | ±1% |

| Testing Speed | 10 seconds/screen | 15 seconds/screen |

| Software Features | Automated testing, data logging | Manual testing, basic reporting |

Note: Supplier data is hypothetical for illustrative purposes. Always consult individual supplier websites for the most up-to-date information.