Best LED LCD Factory: A Comprehensive GuideFinding the right Best led lcd factory can be challenging. This guide helps you navigate the complexities of choosing a manufacturer, focusing on factors crucial for quality, reliability, and cost-effectiveness. We'll explore key considerations, offer insights into the manufacturing process, and point you towards resources to help you make an informed decision.

Understanding the LED LCD Manufacturing Process

From Raw Materials to Finished Product

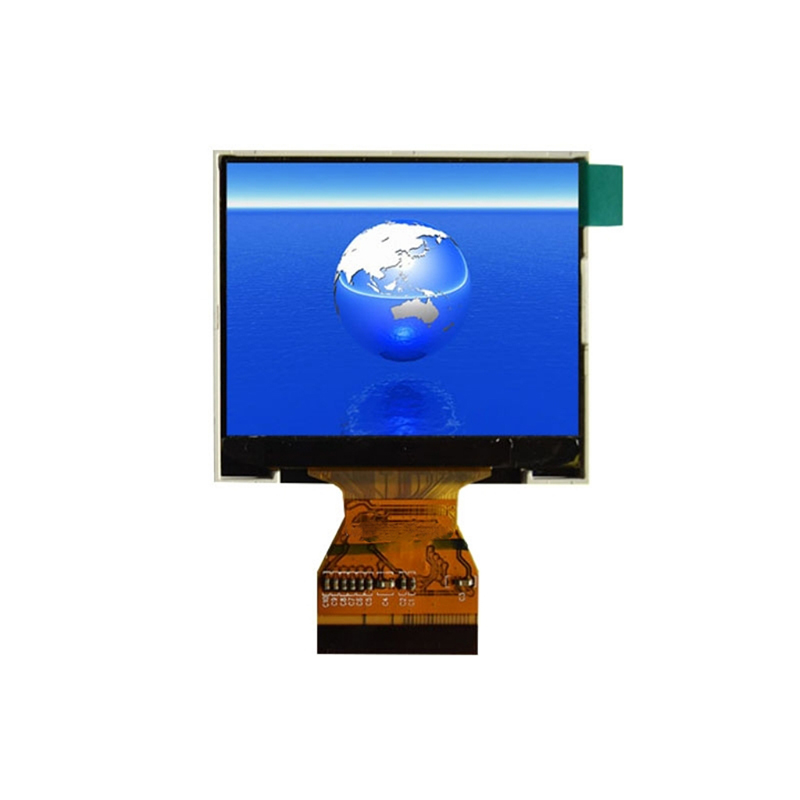

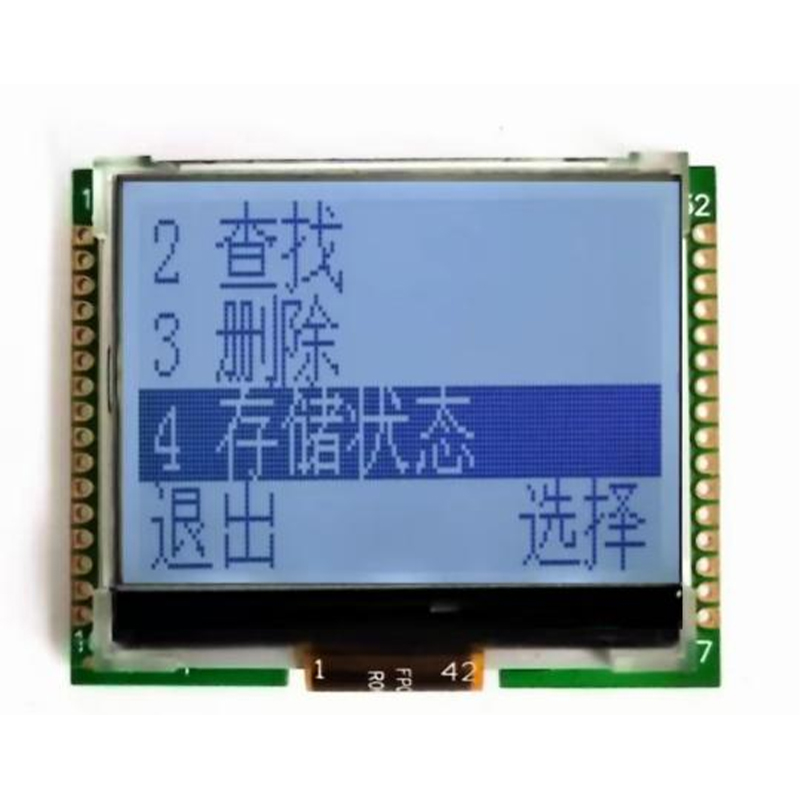

The creation of an LED LCD involves a multi-stage process, starting with the sourcing of high-quality raw materials. This includes the liquid crystal itself, the backlights (LEDs), and the various substrates and components that make up the screen. Precision manufacturing techniques are critical at every step, ensuring consistent quality and performance. Modern

Best led lcd factory utilize advanced automation and rigorous quality control measures.

Key Components and Technologies

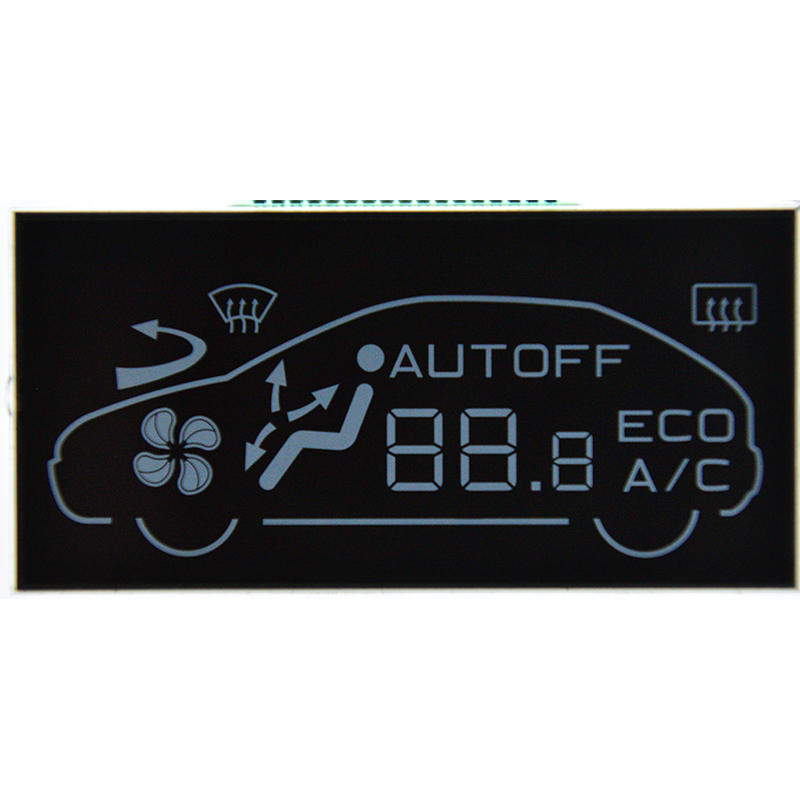

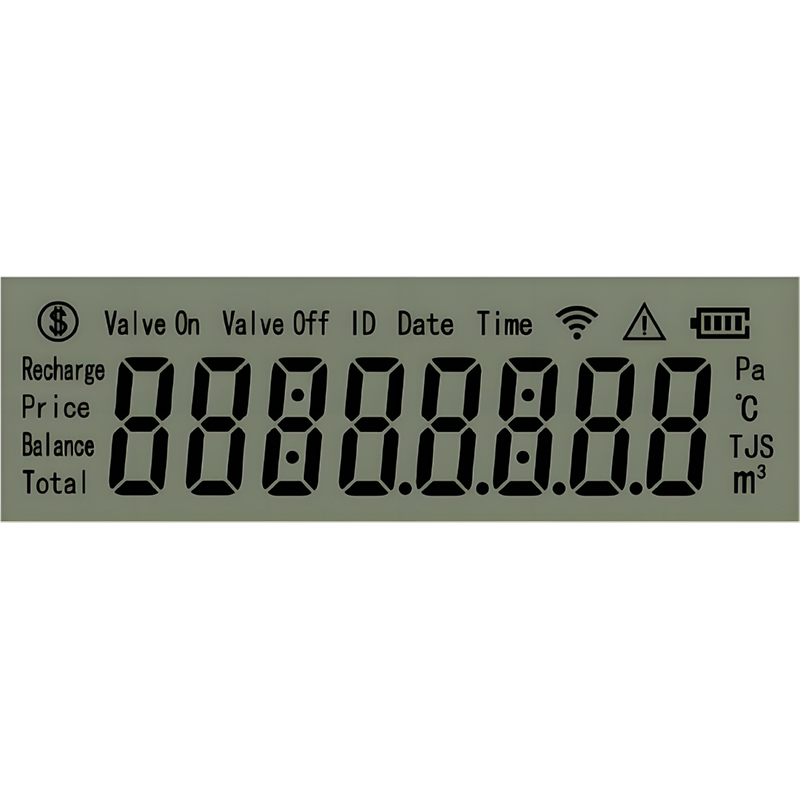

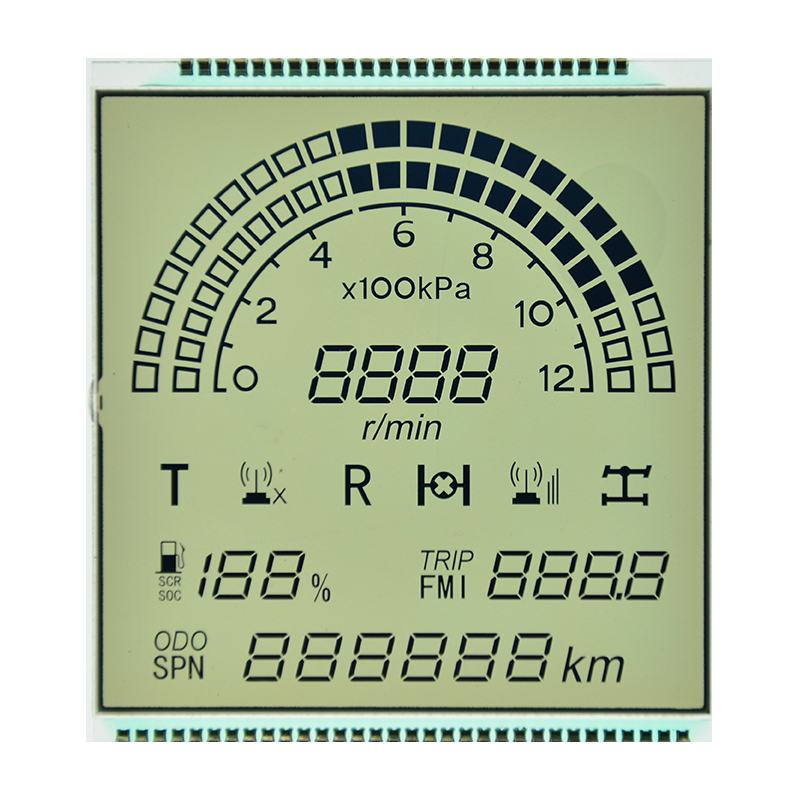

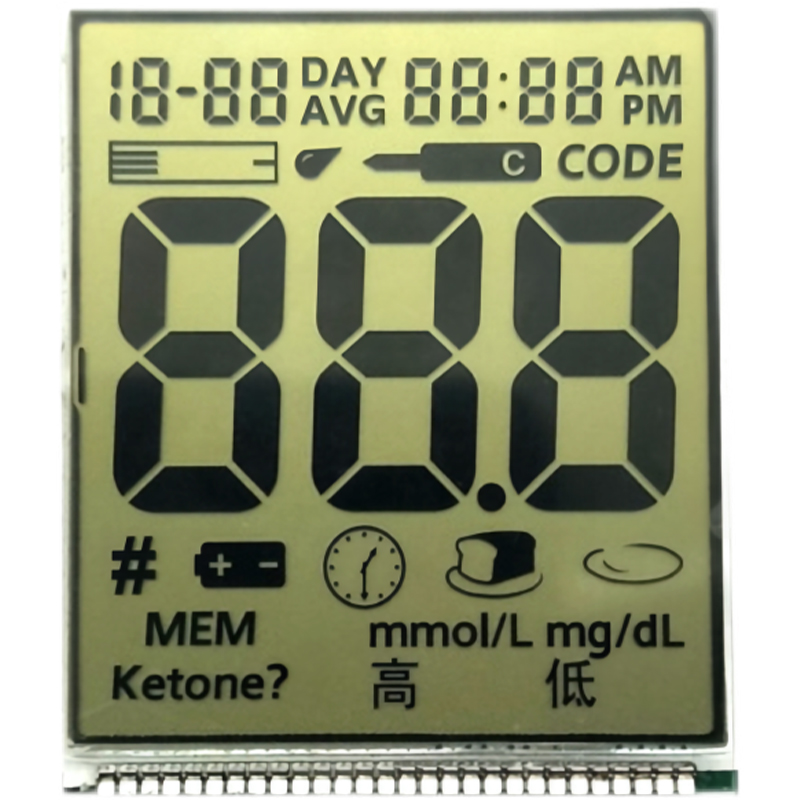

The performance of an LED LCD depends heavily on the quality of its components. Key elements include the type of LEDs used (for example, edge-lit or direct-lit backlighting), the resolution of the display (measured in pixels), and the response time (affecting image clarity and motion blur). Advanced technologies, such as local dimming (allowing for better contrast), are also important considerations. Understanding these elements is key to selecting a manufacturer capable of delivering your desired specifications.

Choosing the Right LED LCD Factory: Key Considerations

Quality Control and Certifications

One of the most important aspects to consider when choosing a

Best led lcd factory is their quality control processes. Reputable manufacturers will hold relevant certifications, demonstrating a commitment to producing high-quality products that meet international standards. Look for certifications like ISO 9001, ISO 14001, and others relevant to the specific product requirements.

Customization and Flexibility

Depending on your needs, the ability to customize your order might be essential. Some manufacturers specialize in mass production, while others offer greater flexibility for smaller batches or specialized projects. Determine your required level of customization and find a factory that can meet your specific needs.

Cost and Lead Times

Cost is always a significant factor. However, remember that the cheapest option isn't always the best. Factor in lead times, shipping costs, and potential hidden expenses when comparing quotes from different manufacturers. Balance cost with quality and reliability.

Finding Your Ideal LED LCD Manufacturer

The search for a reliable

Best led lcd factory can be simplified by leveraging online resources and industry directories. Look for manufacturers with transparent communication, detailed product specifications, and a strong track record. Request samples to evaluate product quality firsthand. Thoroughly review their quality control procedures and certifications.For instance, consider exploring companies with proven expertise in the field, such as

Dalian Eastern Display Co., Ltd. They offer a wide range of LED LCD solutions. Remember to always conduct due diligence and compare several options before making a decision.

Comparison Table: Key Features of Different LED LCD Factories

| Factory | Minimum Order Quantity | Lead Time (weeks) | Certifications | Customization Options |

| Factory A | 1000 units | 8-10 | ISO 9001 | Limited |

| Factory B | 500 units | 6-8 | ISO 9001, ISO 14001 | Moderate |

| Factory C | 200 units | 4-6 | ISO 9001, RoHS | High |

Note: This table is for illustrative purposes only. Specific details will vary depending on the actual factory.Remember to carefully evaluate each factor and choose the

Best led lcd factory that best aligns with your project’s needs and budget. This comprehensive guide provides a starting point for your research; further investigation is essential to making the right choice for your specific requirements.