Discover how to source high-quality LCD screens at competitive prices. This guide explores key factors to consider when selecting a Best Low Cost LCD factory, including production capabilities, quality control, and logistical considerations. We'll also delve into the importance of understanding your specific needs to ensure a successful partnership.

Before embarking on your search for a Best Low Cost LCD factory, clearly define your requirements. Consider factors like screen size, resolution, response time, brightness, contrast ratio, and power consumption. The more precise your specifications, the easier it will be to find a suitable manufacturer. Accurate specifications will also help avoid costly mistakes and delays later in the process.

Your production volume significantly impacts your choice of manufacturer. Smaller orders might be better suited to companies specializing in smaller-batch production, while large-scale projects require manufacturers with substantial capacity. Establish a realistic timeline for your project to ensure the factory can meet your deadlines. Delays can be costly, impacting your project's overall budget and market entry.

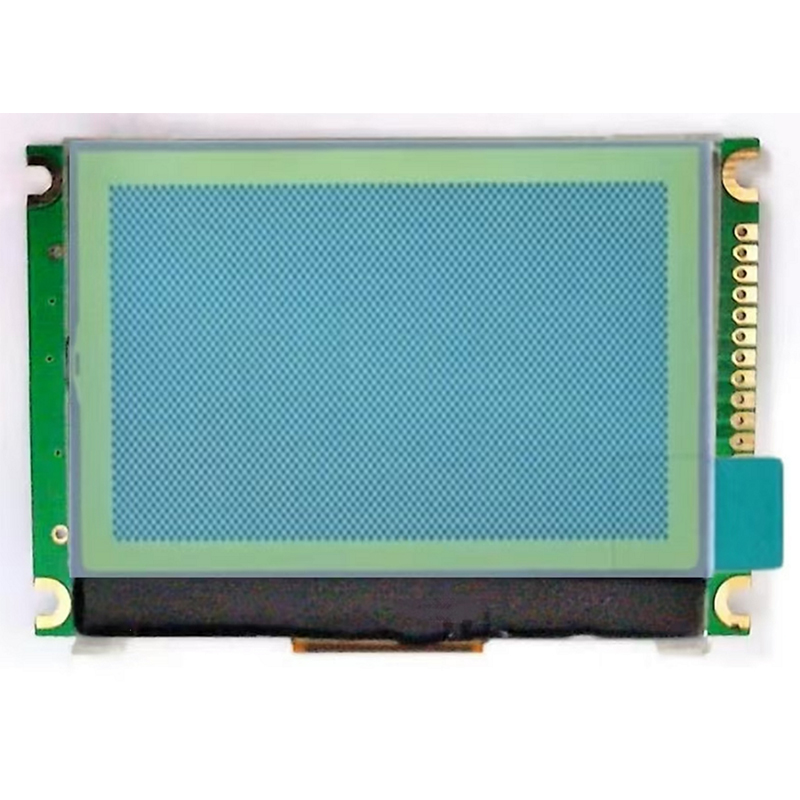

Investigate the potential factory's production process and technological capabilities. Look for certifications like ISO 9001, which indicates a commitment to quality management. Review their equipment and facilities to ensure they can handle your specific LCD requirements. Understanding their technology will help assess whether the Best Low Cost LCD factory matches your need for long-term partnerships.

A reputable Best Low Cost LCD factory will have a robust quality control system in place. Inquire about their testing procedures and defect rates. Request samples to evaluate the quality firsthand. A rigorous quality control process minimizes defects and ensures a consistent product, thus reducing your overall costs due to fewer returns and replacements.

Consider the factory's location and its impact on shipping costs and lead times. A closer factory could reduce shipping expenses and lead times but might not always offer the best price. Explore options that balance cost and logistical efficiency. Negotiating favorable shipping terms and understanding the entire supply chain process is essential for cost-effective procurement.

The cost of LCDs is influenced by several factors:

| Factor | Impact on Cost |

|---|---|

| Screen Size | Larger screens generally cost more. |

| Resolution | Higher resolutions typically increase the cost. |

| Technology (e.g., IPS, TN) | Different technologies offer varying price points. |

| Order Volume | Larger orders often lead to lower per-unit costs. |

Thorough research is crucial. Utilize online resources, attend industry trade shows, and network with other professionals in the field. Don't hesitate to request quotes from multiple manufacturers to compare pricing and services. A reliable and experienced partner is as important as low cost. Consider long-term partnerships, exploring possibilities of collaboration for mutual benefits and growth.

For a reliable and high-quality source of LCD screens, consider Dalian Eastern Display Co., Ltd.. They offer a wide range of options to meet diverse project needs and always strive to provide the Best Low Cost LCD factory experience. Their commitment to quality and customer satisfaction makes them a top choice for various industries.

Remember, the best low-cost factory depends on your specific needs. By carefully evaluating your requirements and conducting thorough research, you can find a reliable and cost-effective supplier for your LCD needs. Choosing a reliable Best Low Cost LCD factory ensures the long-term success of your project.