This guide helps you navigate the landscape of LVDS LCD tester factories, providing crucial factors to consider when selecting a supplier. We'll explore key features, functionalities, and considerations to ensure you find the perfect fit for your needs. Learn how to evaluate different manufacturers and make an informed decision.

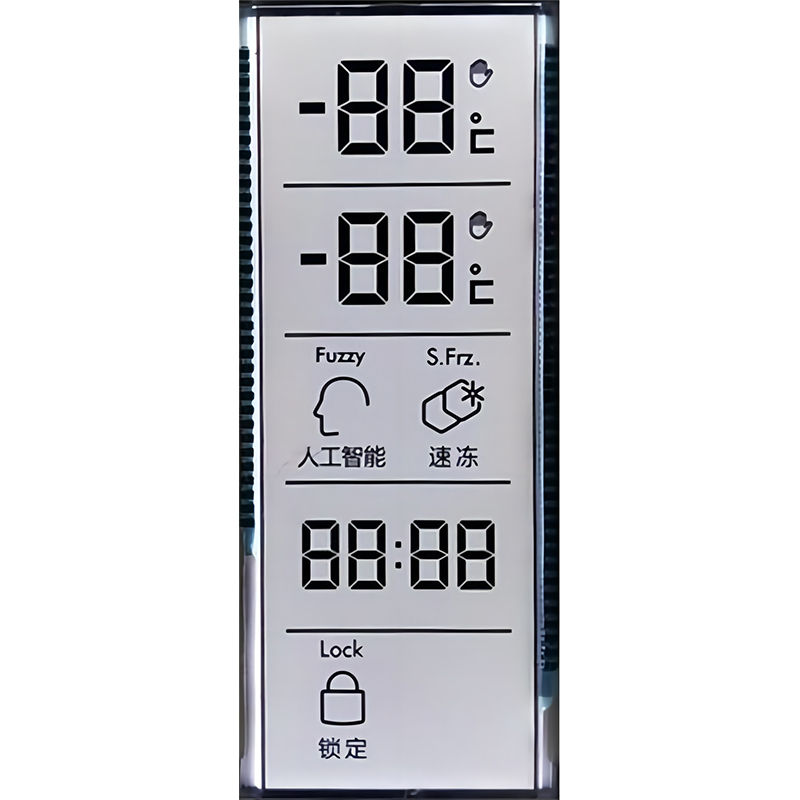

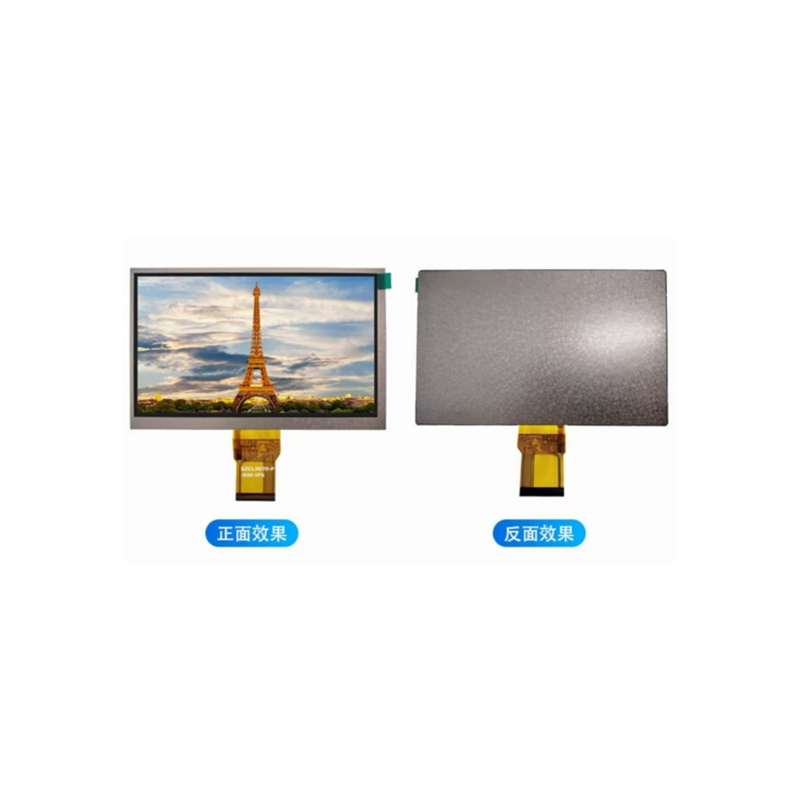

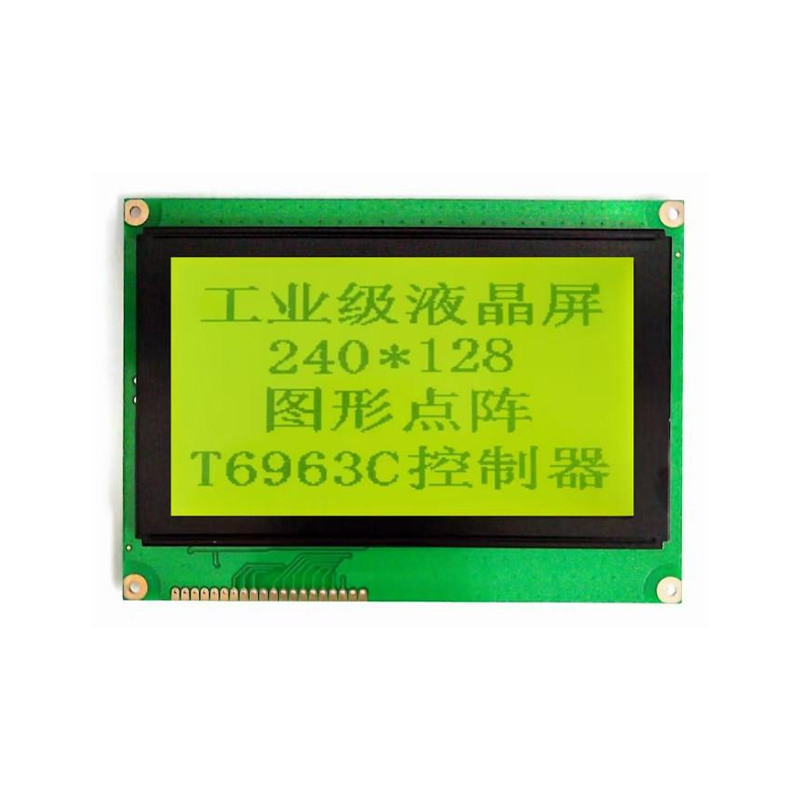

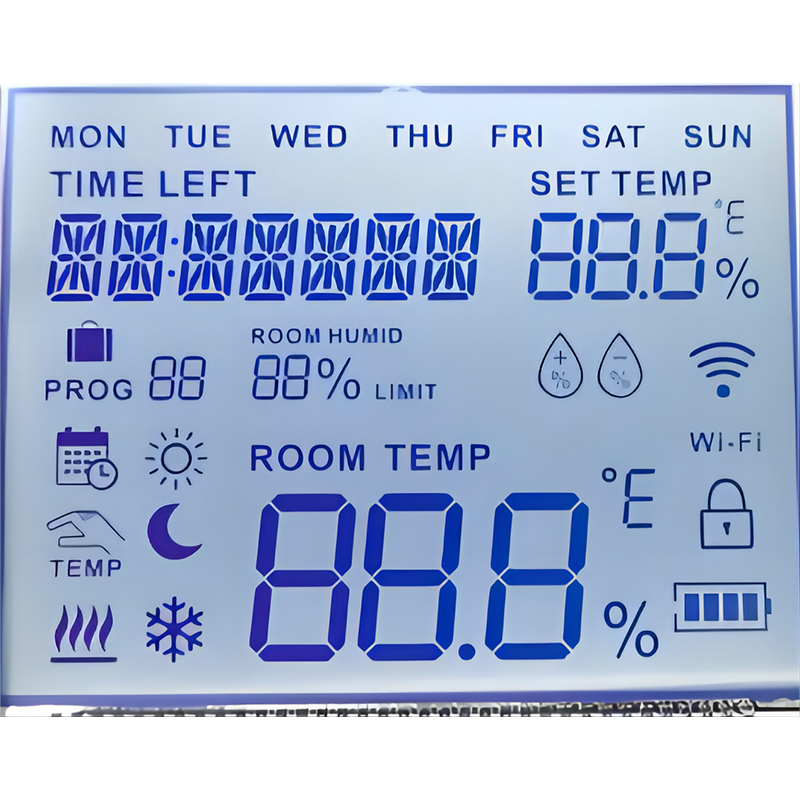

An LVDS (Low-Voltage Differential Signaling) LCD tester is a crucial tool for manufacturers and technicians involved in the production and repair of LCD screens. These testers verify the functionality and integrity of LCD panels, ensuring they meet quality standards. They typically test various aspects, including backlight, image display, and touch functionality (if applicable). The choice of the right Best lvds lcd tester factory is critical for consistent product quality.

When evaluating different LVDS LCD tester factories and their products, consider the following key features:

Selecting the ideal Best lvds lcd tester factory requires careful consideration of several factors. These include:

To make an informed decision, create a comparison table of potential LVDS LCD tester factories, considering factors such as pricing, lead times, capabilities, and customer reviews. Consider looking at online reviews and industry forums for feedback from other users.

| Factory | Testing Capabilities | Price Range | Lead Time |

|---|---|---|---|

| Factory A | High Resolution, Wide Range of Interfaces | $XXX - $YYY | 2-4 weeks |

| Factory B | Limited Resolution, Basic Interfaces | $ZZZ - $WWW | 1-2 weeks |

| Factory C (Dalian Eastern Display Co., Ltd.) | Customizable, High Precision | Contact for Quote | Contact for Quote |

Finding the Best lvds lcd tester factory involves careful research and a thorough evaluation of potential suppliers. By considering the factors discussed in this guide and conducting a comprehensive comparison, you can select a factory that meets your specific needs and ensures the quality of your LCD products. Remember to always prioritize quality, reliability, and strong after-sales support.