This guide provides a comprehensive overview of effective strategies for troubleshooting LVDS (Low-Voltage Differential Signaling) connections, focusing on efficient exit techniques for testers. We explore various testing methods, common issues, and practical solutions to help you quickly identify and resolve problems with your LVDS setup. Learn about advanced techniques and best practices to optimize your testing workflow.

Effective LVDS tester exit strategies begin with understanding potential signal degradation sources. Common issues include impedance mismatches, excessive noise, crosstalk, and connector problems. A thorough understanding of these issues is crucial for effective troubleshooting.

When troubleshooting LVDS signals, pinpointing the faulty component is key. This often involves using specialized equipment like oscilloscopes and logic analyzers to examine signal quality. Systematic testing, isolating sections of the circuit, helps narrow down the problem area. Remember to consider the entire signal path, from source to destination, when identifying the root cause.

A simple yet effective technique is a loopback test. This involves connecting the output of the LVDS tester back to its input. This allows you to verify the functionality of the tester itself, eliminating the tester as a potential source of the problem. Success here indicates the issue lies elsewhere in your system.

An oscilloscope provides invaluable insight into signal characteristics. It allows for precise measurement of voltage levels, rise/fall times, and jitter. Observing these parameters can quickly reveal signal degradation or anomalies. Analyzing these characteristics helps pinpoint the location of the problem within the LVDS signal path.

For digital signal analysis, a logic analyzer is a powerful tool. It captures and displays the digital data being transmitted over the LVDS lines. This allows you to check for errors or inconsistencies in the transmitted data, potentially indicating a problem with the data source or the receiving end.

For complex systems, a systematic approach is crucial. Isolate sections of the LVDS connection, testing each segment individually. This helps to pinpoint the faulty component or connection. If possible, try substituting components (e.g., cables, connectors) to rule out faulty hardware.

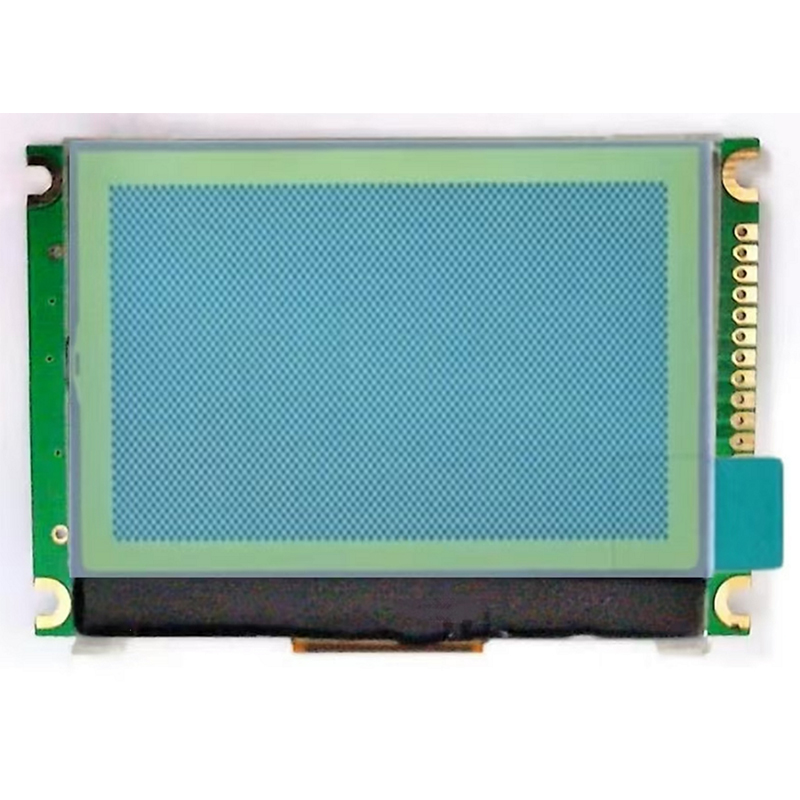

For advanced troubleshooting, consider using specialized LVDS testers designed for comprehensive signal analysis and diagnostics. These tools offer features that extend beyond basic loopback tests, providing more detailed information about the health and quality of your LVDS connections. Many manufacturers, such as those who supply LCD panels, offer support and testing resources.

Selecting the appropriate LVDS tester depends on the complexity of your system and the specific needs of your testing requirements. Consider factors such as the number of channels, bit rates, and any specific features (such as eye diagrams or jitter measurements) that might be beneficial. Always consult the manufacturer's specifications to ensure compatibility with your LVDS system.

For more information about high-quality LCD panels and related technologies, you might find Dalian Eastern Display Co., Ltd. a valuable resource. They offer a range of display solutions.

Successfully exiting an LVDS tester involves understanding the signal path, utilizing appropriate testing tools, and employing systematic troubleshooting methods. By combining these techniques, you can efficiently identify and resolve issues, ensuring the reliable operation of your LVDS systems. Remember to always prioritize safety and follow manufacturer guidelines when working with electronic equipment.