This guide helps you navigate the market for best lvds tester factory, providing crucial factors to consider when selecting a supplier for your LVDS testing needs. We'll explore key features, considerations, and resources to ensure you make an informed decision.

Low-Voltage Differential Signaling (LVDS) is a crucial technology in various electronic devices. Accurate and reliable testing is paramount to ensuring product quality and performance. A high-quality best lvds tester factory provides the equipment and expertise needed for thorough testing procedures. The choice of a best lvds tester factory impacts efficiency, accuracy, and the overall success of your project.

Different best lvds tester factory offer varying testing capabilities. Consider the specific LVDS parameters you need to test, such as signal integrity, data rates, and error rates. Ensure the factory's equipment covers your requirements. Look for factories that can handle various LVDS standards and interface types.

The reputation and quality control processes of the best lvds tester factory are critical. Check for industry certifications, such as ISO 9001, which indicates adherence to quality management systems. High-quality factories will have robust quality control measures in place to ensure accurate and reliable results.

A reputable best lvds tester factory offers technical expertise and support throughout the testing process. Access to knowledgeable engineers is invaluable for troubleshooting and resolving any issues that may arise. Consider the factory's responsiveness and the level of support offered.

Production capacity and turnaround time are essential factors, particularly for large-scale projects. A best lvds tester factory with sufficient capacity and efficient processes can meet your project deadlines effectively. Discuss lead times and production capabilities with potential suppliers.

Compare pricing and cost-effectiveness among different best lvds tester factory. Consider not only the upfront costs but also the long-term value and potential savings associated with accurate testing and reduced product defects. Transparency in pricing is important.

Thoroughly researching potential suppliers is essential. Start by identifying several potential best lvds tester factory and then compare them based on the factors discussed above. This includes examining their online presence, client testimonials, and their capabilities.

Several industry organizations and publications offer insights into LVDS testing and related technologies. These resources can provide valuable background information and help you make an informed decision. Always verify information from multiple sources.

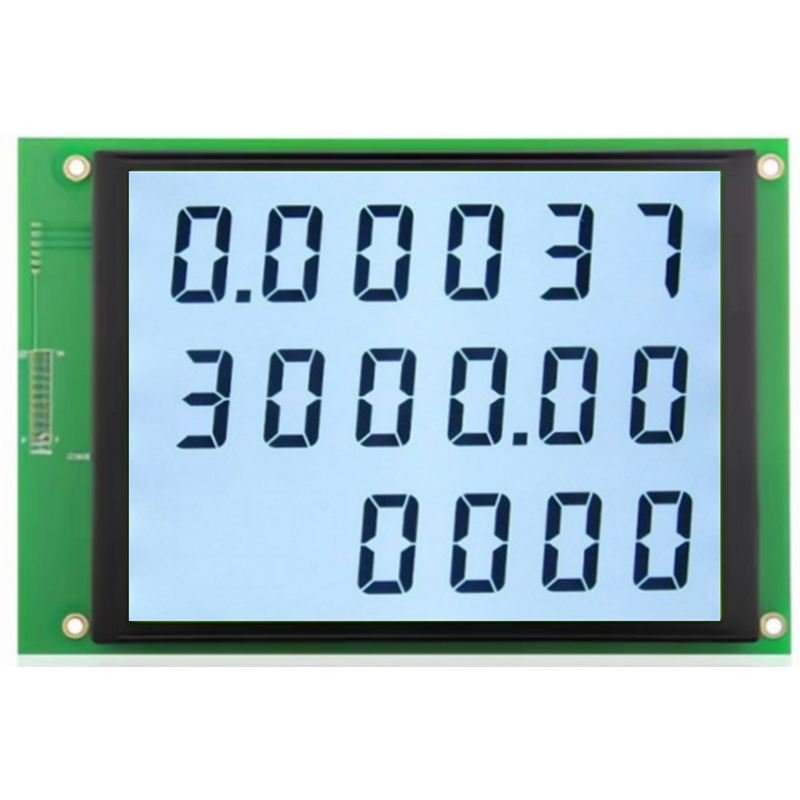

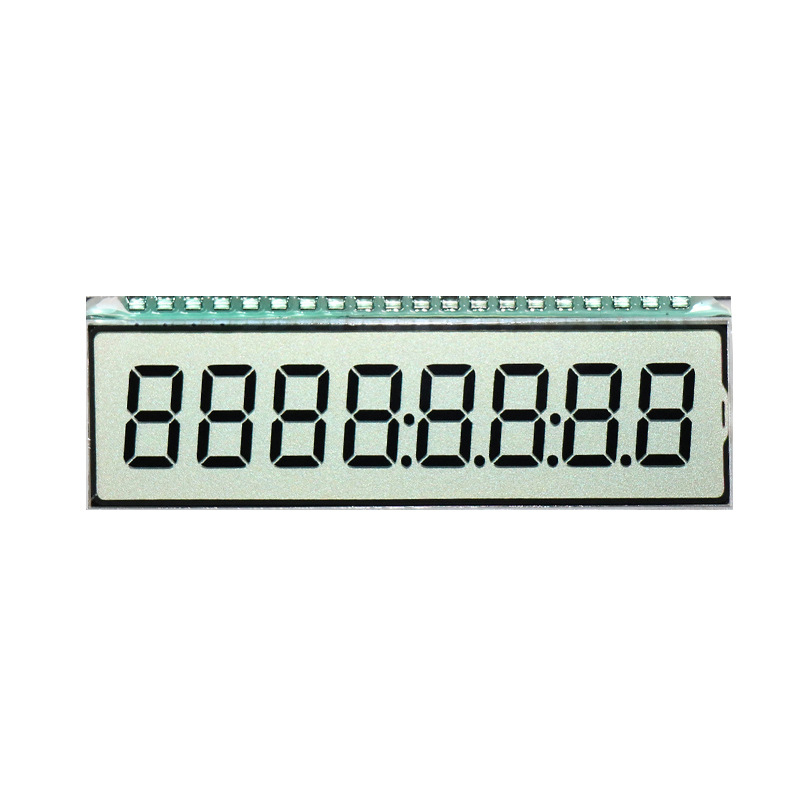

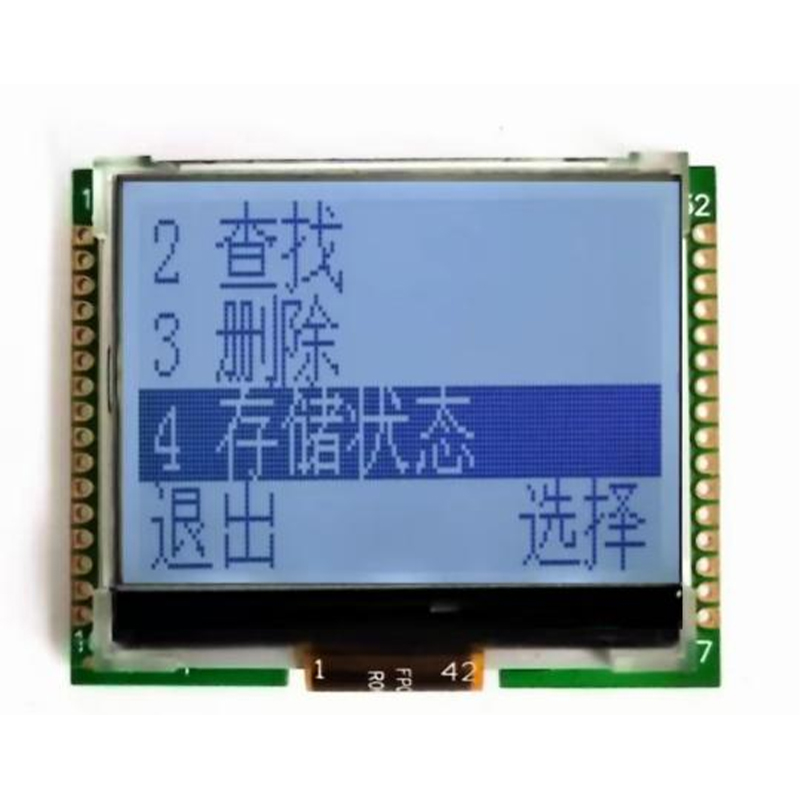

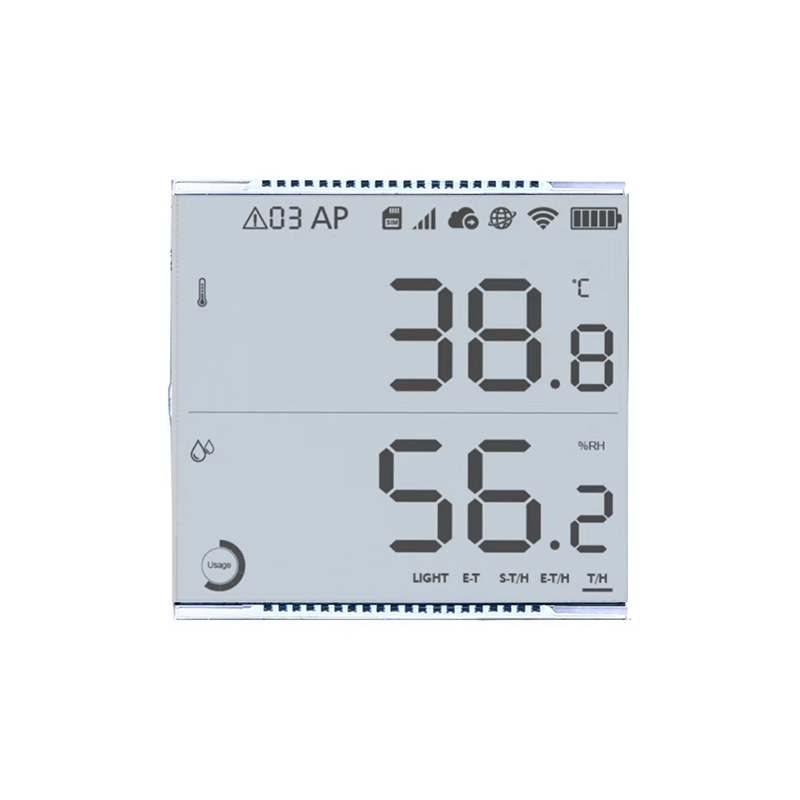

For high-quality LCD and display solutions, consider exploring Dalian Eastern Display Co., Ltd. They provide a comprehensive range of products and services in the display industry.

Choosing the best lvds tester factory requires careful consideration of various factors. By following this comprehensive guide, you can effectively evaluate potential suppliers, ensuring you select a partner that meets your specific needs and contributes to the success of your project. Remember to prioritize quality, reliability, and technical expertise when making your decision.