This guide explores the world of mechanical dot matrix displays, comparing different types, outlining their applications, and helping you choose the best one for your needs. We'll delve into key features, advantages, disadvantages, and considerations to make an informed decision. Learn about resolution, character size, durability, and more to find the perfect mechanical dot matrix display for your project.

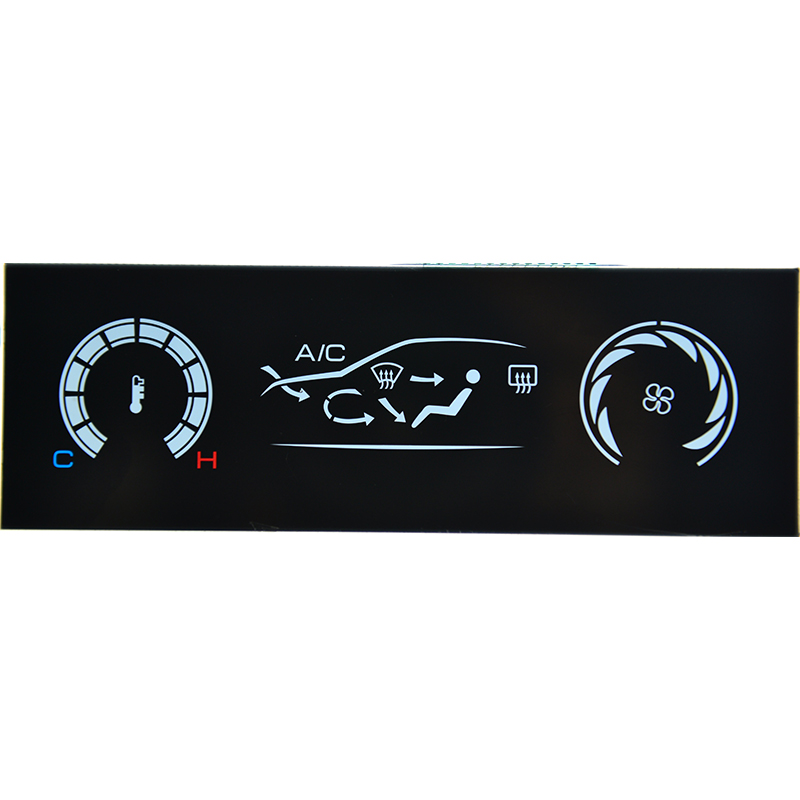

Unlike their LED or LCD counterparts, mechanical dot matrix displays utilize physical components to form characters. These often involve small pins or segments that are mechanically activated to create the desired pattern. This technology, while older, offers unique advantages in specific scenarios. They are known for their robustness and ability to function in harsh environments where electronic displays might fail.

There are several variations in design and implementation. Some common types include those using rotating drums, print heads, and even electromechanical systems. The choice of technology often depends on the required resolution, character size, and overall durability needs. The specific mechanics differ depending on the manufacturer and model, leading to variation in performance characteristics.

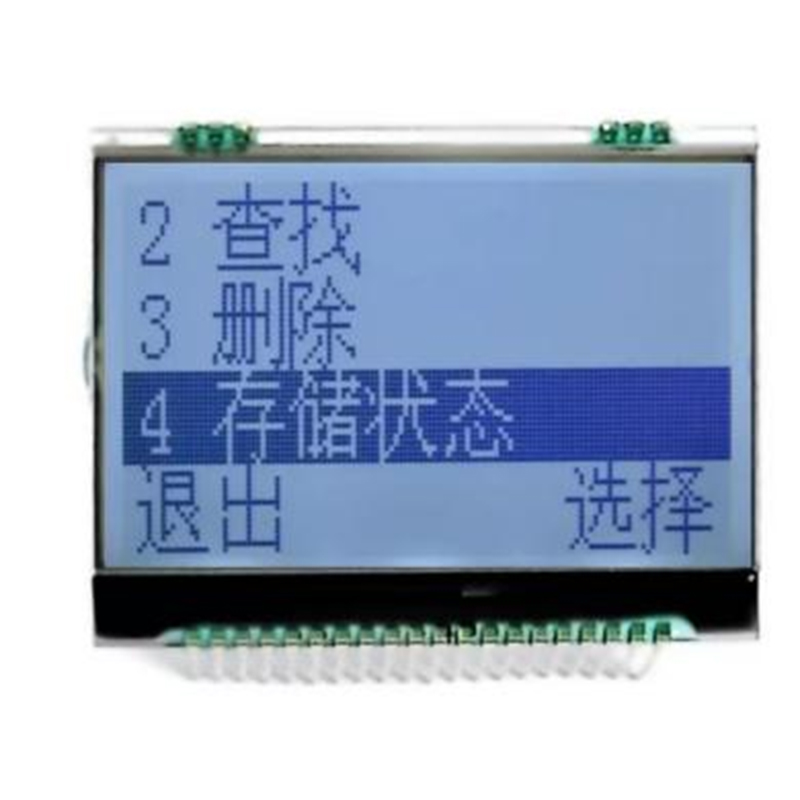

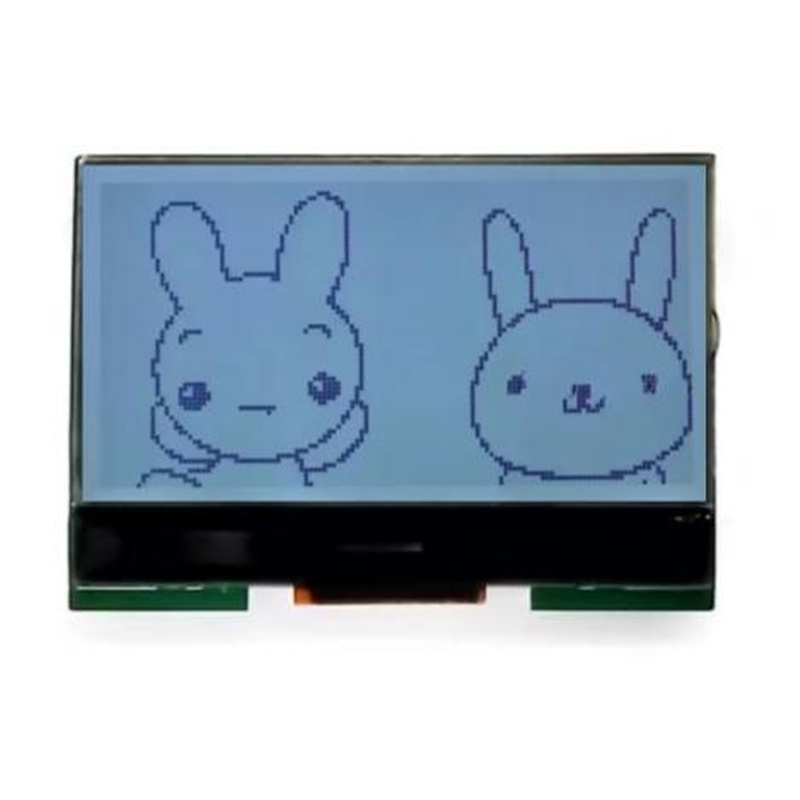

The resolution of a mechanical dot matrix display determines the clarity and detail of the displayed characters. Higher resolution generally results in sharper, more legible text. Character size is another crucial factor, influencing readability from a distance. The ideal resolution and character size depend heavily on the application and viewing distance.

Mechanical dot matrix displays are often praised for their robustness. They can withstand vibration, shock, and extreme temperatures—making them suitable for industrial, outdoor, and other demanding environments. However, their mechanical nature means they may have a limited lifespan compared to electronic counterparts.

Power consumption varies significantly among different mechanical dot matrix display models. It's essential to check the specifications to ensure compatibility with your power supply. Operating voltage is another crucial consideration.

The way a mechanical dot matrix display interacts with the controlling system is another key factor. Understanding the supported interface (e.g., parallel, serial) and communication protocols is essential for seamless integration into your project.

Selecting the appropriate mechanical dot matrix display depends on your specific application. Consider the following factors:

While providing a specific comparison of models requires extensive research and testing, it is important to investigate options from various manufacturers based on your requirements. Look for detailed specifications including the aspects discussed above. Due to the specific nature of manufacturing, information about particular models may be obtained directly from suppliers.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Resolution | (Example: 20x4) | (Example: 16x2) | (Example: 24x8) |

| Character Size | (Example: 5x7) | (Example: 7x9) | (Example: 5x7) |

| Power Consumption | (Example: 5W) | (Example: 3W) | (Example: 7W) |

Note: Model A, B, and C are placeholders. Specific model information should be obtained from manufacturers. This table is for illustrative purposes.

Choosing the best mechanical dot matrix display involves careful consideration of its intended application and operational environment. By understanding the key features and specifications, you can select a solution that meets your exact requirements for reliability, readability, and durability. Remember to consult manufacturer specifications for precise details on specific models.

For more information on custom LCD solutions, explore the possibilities with Dalian Eastern Display Co., Ltd., a leading provider of innovative display technologies.