Best Ways to Handle microSD SPI Interface ExitsUnderstanding and effectively managing the exit conditions of your microSD SPI interface is crucial for robust system design. This guide provides a comprehensive overview of common issues, best practices, and solutions for ensuring reliable data transfer and error handling.

Understanding the microSD SPI Interface

The microSD card, using the SPI interface, communicates with a host controller via four main lines: MOSI (Master Out Slave In), MISO (Master In Slave In), SCK (Serial Clock), and CS (Chip Select). Proper management of these lines, especially during initialization and exit, is key to avoiding data corruption and system instability. A common problem lies in improper

Best microsd spi interface exit procedures. A poorly managed exit can leave the card in an unpredictable state, potentially leading to data loss or requiring a power cycle to recover.

Common Exit Issues

Several factors can lead to problems with

Best microsd spi interface exit: Improper Chip Deselection: Failing to properly deselect the microSD card (CS line high) before switching tasks or powering down can result in ongoing communication attempts, leading to data corruption or system hangs. Incomplete Transfers: Interrupts or unexpected events might interrupt a data transfer, leaving the card in a mid-transaction state. This is especially problematic when writing data. Power Loss During Write Operations: A sudden power loss during a write operation can leave the card's file system in an inconsistent state, resulting in data loss or corruption.

Best Practices for microSD SPI Interface Exit

To mitigate these risks, implementing these best practices is vital:

1. Always Deselect the Card

Before releasing the SPI bus or powering down, ensure the CS line is high, effectively deselecting the microSD card. This prevents unwanted interactions and ensures a clean exit.

2. Implement Proper Error Handling

Include robust error-handling mechanisms to detect and respond to potential issues such as communication errors, write errors, or card removal during operation. This might involve checking status registers and implementing retry mechanisms.

3. Use Write Protection

When possible, utilize the write-protect function of the microSD card to prevent accidental data corruption during the

Best microsd spi interface exit process or in the event of unexpected interruptions.

4. Buffered Writes

For improved data integrity, employ buffered writes. This allows data to be written to a buffer before transferring it to the microSD card. In case of interruptions, the buffer’s contents can be safely written once the system recovers.

Hardware Considerations

The hardware itself can also impact the

Best microsd spi interface exit. Ensuring a stable power supply is critical. Sudden voltage drops can severely compromise data integrity during writing. High-quality components are essential for reliable performance. Using a robust SPI controller with proper error detection capabilities also reduces the risk of issues.

Software Considerations

Appropriate software management plays a crucial role in ensuring a successful and safe

Best microsd spi interface exit. The driver software should carefully manage the CS line and implement robust error handling routines. Consider using DMA transfers for faster and more efficient data transfer.

Troubleshooting Tips

If you encounter problems with your microSD SPI interface, here are some initial troubleshooting steps: Check Power Supply: Ensure the power supply is stable and meets the requirements of the microSD card and its controller. Inspect Wiring: Carefully verify that all SPI connections are properly made and secure. Test the Card: Try the microSD card in another system to rule out a faulty card. Review Code: Thoroughly check your code for potential issues in the

Best microsd spi interface exit routine.

Conclusion

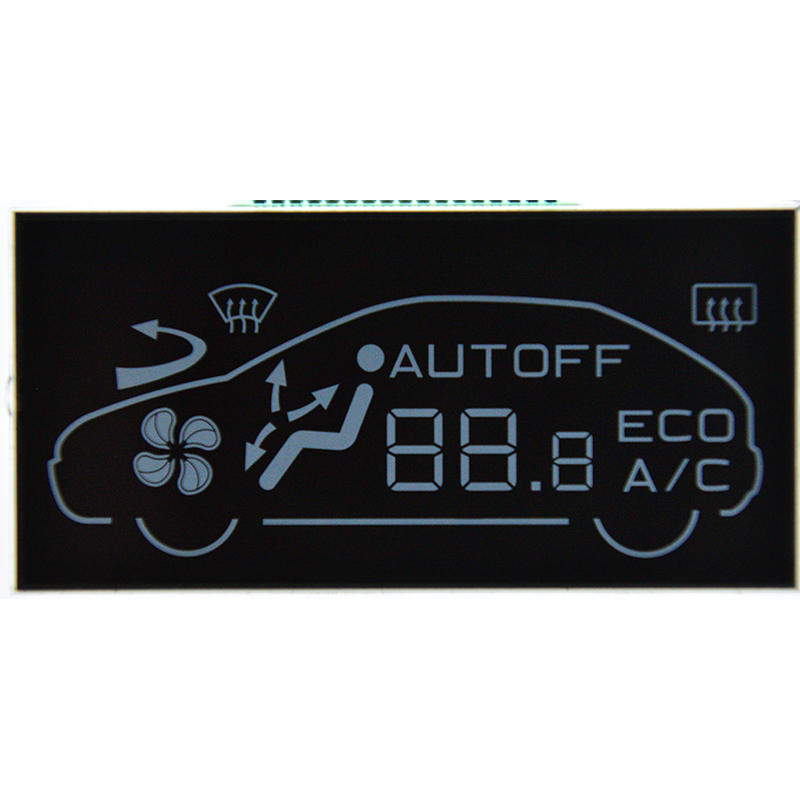

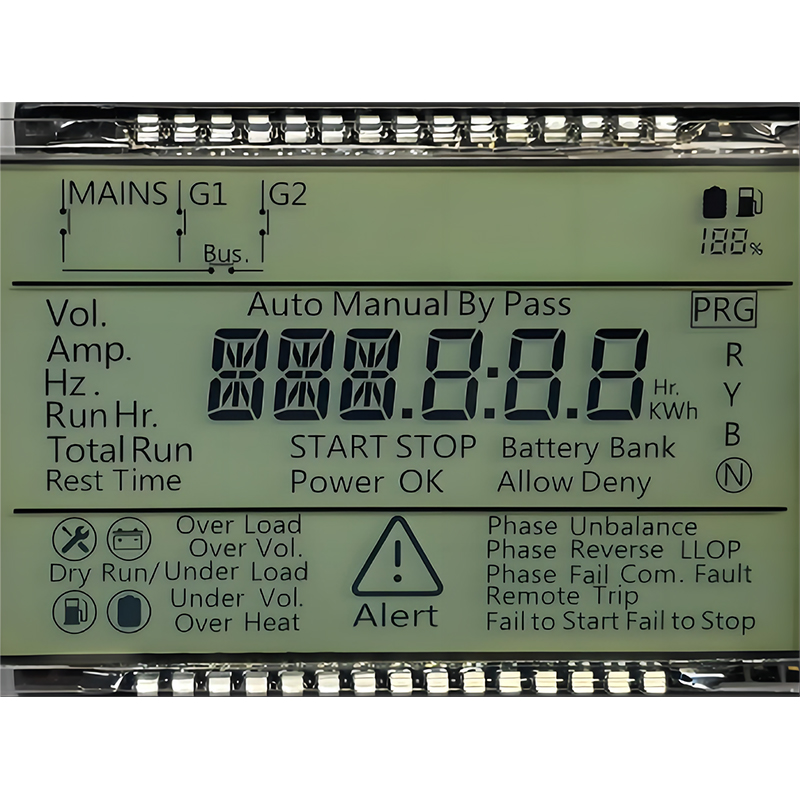

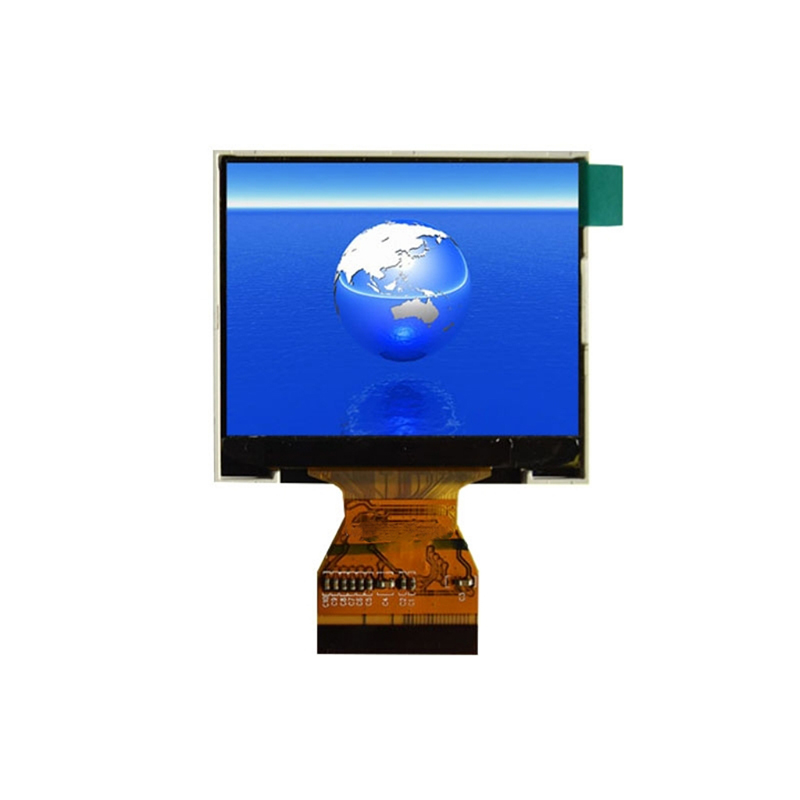

Implementing these best practices and understanding the potential pitfalls helps prevent common problems with the microSD SPI interface. Prioritizing robust error handling and ensuring proper chip deselection procedures are fundamental steps towards reliable and efficient data management. Remember to always refer to the specifications of your specific microSD card and SPI controller for optimal results. For high-quality LCD displays for your embedded systems, consider exploring the capabilities of [Dalian Eastern Display Co., Ltd.](https://www.ed-lcd.com/)

https://www.ed-lcd.com/. Their displays are known for their reliability and performance.