This comprehensive guide helps you navigate the landscape of NodeMCU OLED display manufacturers, providing insights into choosing the ideal factory for your project needs. We'll cover key factors to consider, explore different display options, and discuss sourcing strategies to ensure quality and efficiency.

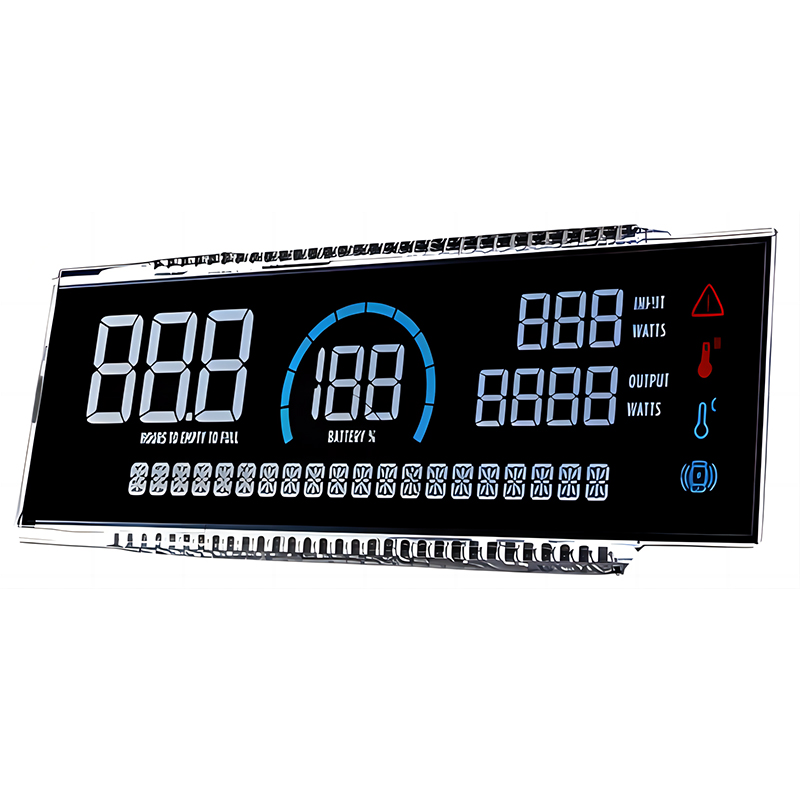

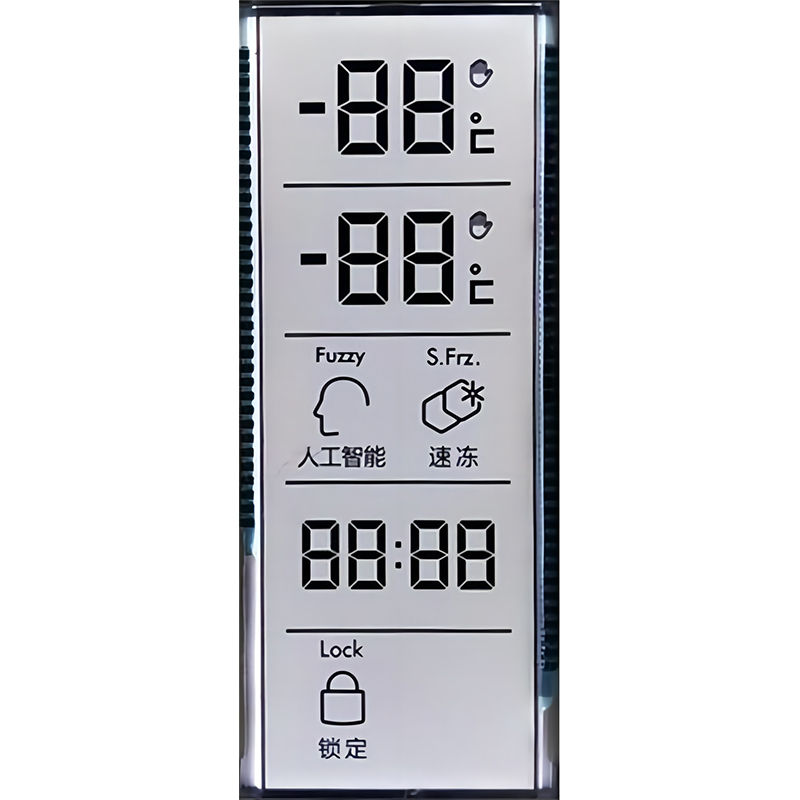

Before embarking on your search for the best NodeMCU OLED display factory, clearly define your project requirements. Consider factors such as screen size (e.g., 0.96-inch, 1.3-inch, 2.2-inch), resolution, color depth (monochrome or color), interface type (I2C, SPI), brightness, power consumption, and operating temperature range. The specific application will dictate these parameters. For example, a small, low-power display might suffice for a simple sensor monitoring application, whereas a larger, higher-resolution display would be suitable for a more complex graphical user interface (GUI).

OLED displays come in various forms. Common types include passive-matrix and active-matrix OLEDs. Active-matrix OLEDs generally offer superior image quality, faster response times, and wider viewing angles but are typically more expensive. Understanding these differences is crucial when selecting a NodeMCU OLED display factory that can meet your technical specifications.

Assess the factory's manufacturing capacity to ensure they can meet your production volume requirements and lead time expectations. A factory with high production capacity is suitable for large-scale projects, while smaller factories might be more appropriate for smaller orders or prototyping. Inquire about their minimum order quantities (MOQs) and average lead times to manage your project timeline effectively. Consider factories with flexible production capabilities to handle fluctuating demands.

Thorough quality control is essential. Look for factories with robust quality management systems (QMS) in place, such as ISO 9001 certification. Inquire about their testing procedures and defect rates to ensure the quality and reliability of the NodeMCU OLED displays they produce. Request samples to assess the display quality firsthand.

Obtain detailed pricing information, including unit costs, setup fees, and shipping charges. Compare quotes from multiple factories to find competitive pricing. Also, clarify payment terms, including payment methods and deadlines.

Effective communication is crucial. Assess the responsiveness and helpfulness of the factory's customer support team. A factory that provides clear, timely, and comprehensive communication will ensure a smoother project execution. Look for factories with multilingual support and readily available contact channels.

Online marketplaces like Alibaba and Global Sources can be a good starting point for finding potential NodeMCU OLED display factories. However, thorough due diligence is vital, including verifying the supplier's credentials and reputation.

Attending industry trade shows and exhibitions provides an opportunity to meet potential suppliers in person, inspect samples, and assess their capabilities firsthand. This direct interaction can facilitate better communication and build stronger relationships.

Directly contacting factories offers a more personalized approach and allows for tailored solutions. This method requires more research and time investment but can potentially lead to more favorable terms and a closer working relationship.

| Factor | Importance |

|---|---|

| Quality Control | High |

| Production Capacity | Medium-High |

| Pricing | Medium |

| Lead Times | Medium-High |

| Communication | High |

Remember to carefully vet any potential NodeMCU OLED display factory before committing to a partnership. Conduct thorough research, request samples, and seek recommendations to ensure a successful project outcome.

For high-quality LCD and OLED display solutions, consider exploring the capabilities of Dalian Eastern Display Co., Ltd. They offer a wide range of display options and are known for their commitment to quality and customer service.