This guide explores the intricacies of achieving the best possible outcome with OCA full lamination exit, focusing on techniques, troubleshooting, and best practices for achieving superior quality and efficiency. We'll cover various aspects to ensure you understand the process fully and can optimize your results.

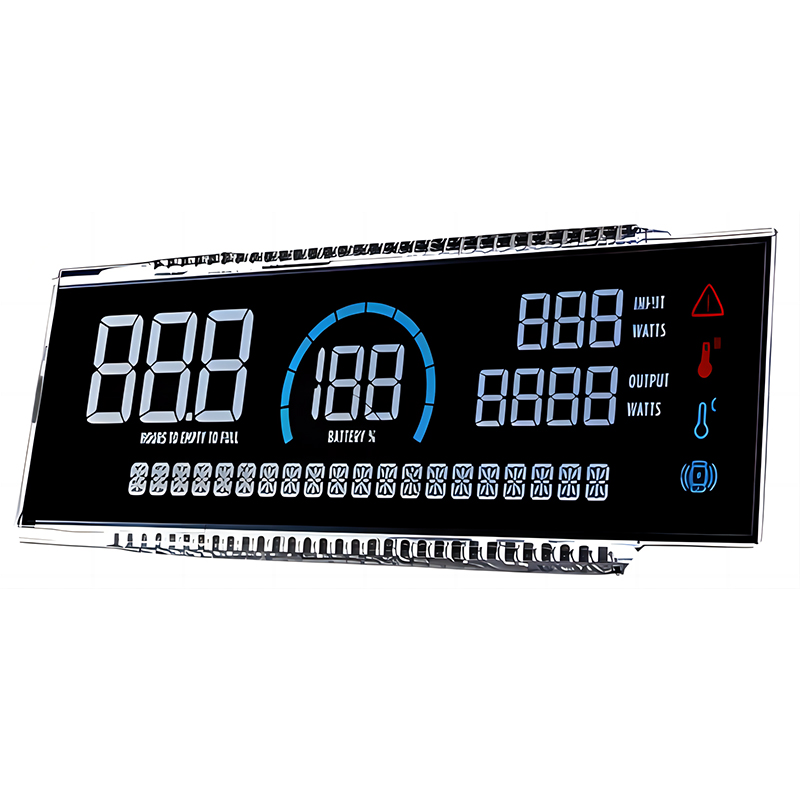

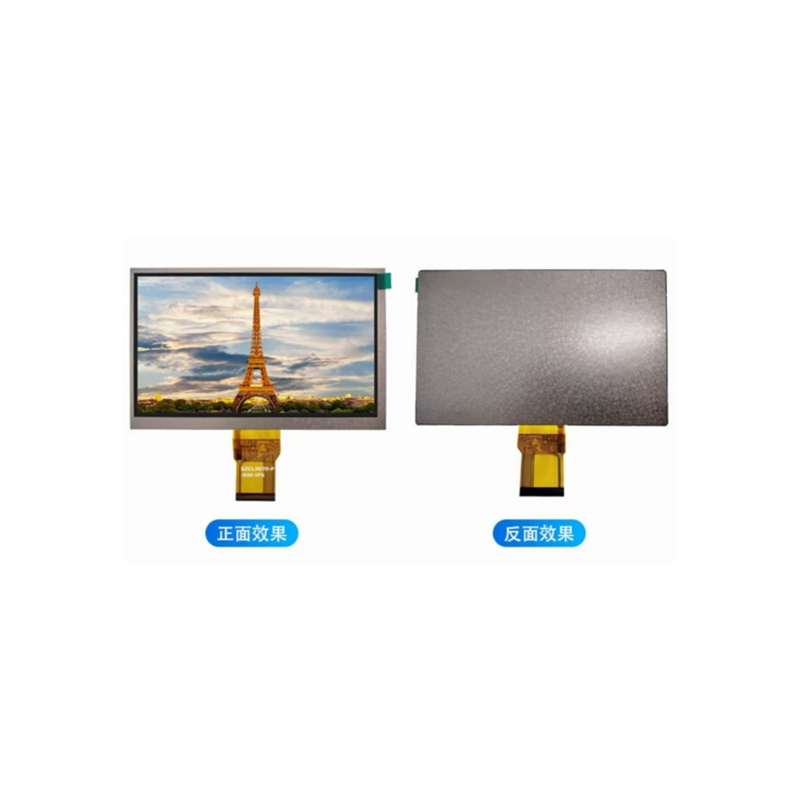

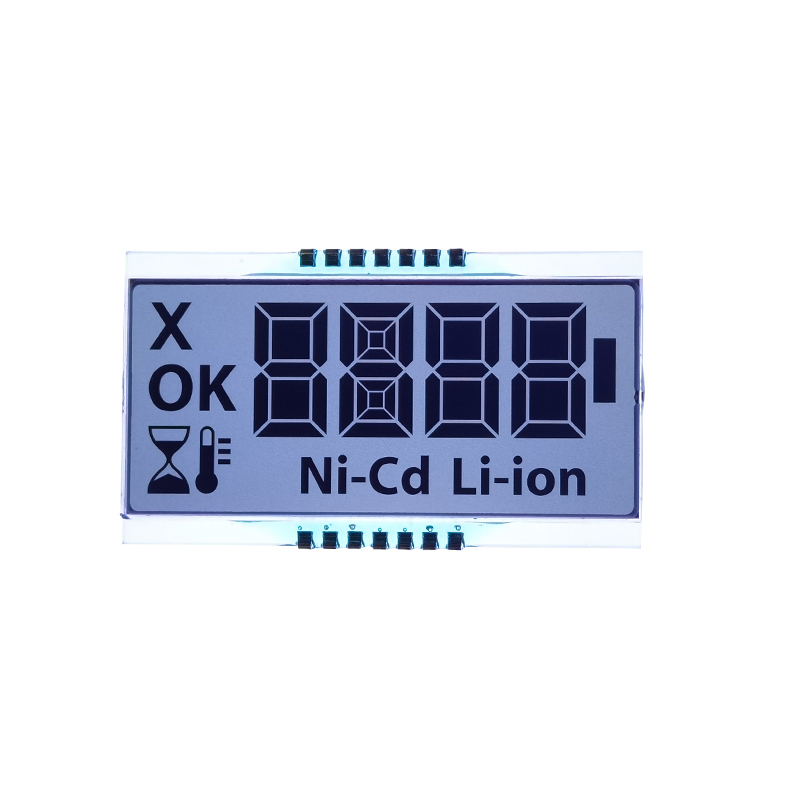

OCA (Optically Clear Adhesive) full lamination is a crucial process in the manufacturing of touch screen displays and other laminated components. It involves bonding two or more substrates, such as glass panels and touch sensors, using a layer of OCA. This creates a robust, optically clear, and pressure-sensitive assembly. The exit refers to the final stage of the lamination process, where the completed laminated assembly is ready for further processing or packaging. A successful OCA full lamination exit signifies a flawless bond, free from bubbles, debris, or other imperfections.

The advantages of OCA full lamination are numerous. It improves the overall visual quality by eliminating air gaps and light reflections, resulting in enhanced clarity and color accuracy. The process also significantly strengthens the assembly, making it more resistant to damage and enhancing its lifespan. Additionally, it contributes to a sleeker and more aesthetically pleasing final product.

Several factors significantly influence the success of OCA full lamination exit. These include pressure, temperature, and time. The precise settings will vary depending on the specific OCA adhesive used and the materials being laminated. Consulting the manufacturer's specifications for both the OCA and the equipment is crucial. Incorrect parameters can lead to issues such as incomplete bonding, bubble formation, or delamination.

The quality of the equipment used plays a vital role in achieving a superior OCA full lamination exit. High-quality lamination machines with precise pressure and temperature control are essential. Additional tools, such as vacuum chambers to remove air pockets and precision alignment systems, contribute to a more efficient and reliable process. For those involved in large-scale production, investing in automated systems is often beneficial.

Despite careful planning, certain issues may arise during the lamination process. Common problems include bubble formation, incomplete bonding, and debris contamination. Understanding the causes of these problems is crucial for effective troubleshooting. For example, bubbles often result from insufficient vacuum or trapped air. Incomplete bonding might be due to inadequate pressure or improper temperature settings. Contamination can be minimized through meticulous cleanliness in the work environment. For comprehensive troubleshooting guidance, referencing the relevant technical manuals is advised.

The choice of OCA adhesive and the quality of the substrates (e.g., glass panels, touch sensors) directly impact the OCA full lamination exit. Selecting high-quality materials from reputable suppliers is paramount. Implementing a robust quality control process throughout the entire lamination process, from material inspection to final product verification, helps ensure consistency and high yields. Regular calibration of the lamination equipment is crucial for maintaining accuracy and avoiding process deviations.

Vacuum lamination significantly enhances the quality of the OCA full lamination exit by effectively removing air bubbles and ensuring complete contact between the substrates and the OCA adhesive. This technique is especially beneficial for larger assemblies or complex laminates.

For high-volume production, automated lamination systems offer significant advantages. These systems ensure consistency, precision, and efficiency, leading to a superior and repeatable OCA full lamination exit. They also reduce the risk of human error.

[Insert a brief, anonymized case study illustrating successful implementation of best practices in OCA full lamination, focusing on achieving a high-quality exit. This could include metrics such as improved yield rates or reduced defect rates.]

For high-quality LCD displays and related components, consider partnering with Dalian Eastern Display Co., Ltd. Their expertise in display technology can help optimize your OCA full lamination process.